process of chrome ore

2023-09-18T02:09:50+00:00

Top 3 Chrome Ore Processing Methods that Get Higher

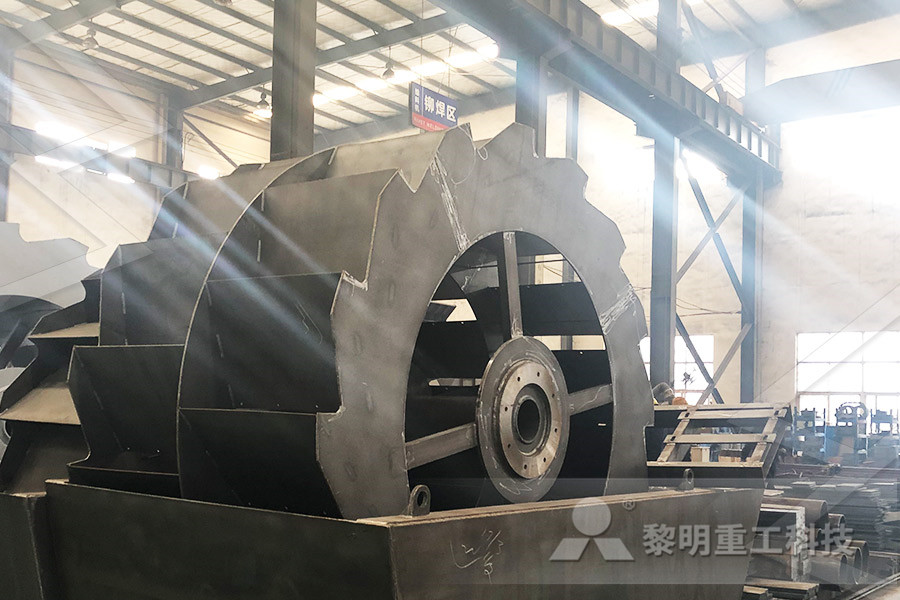

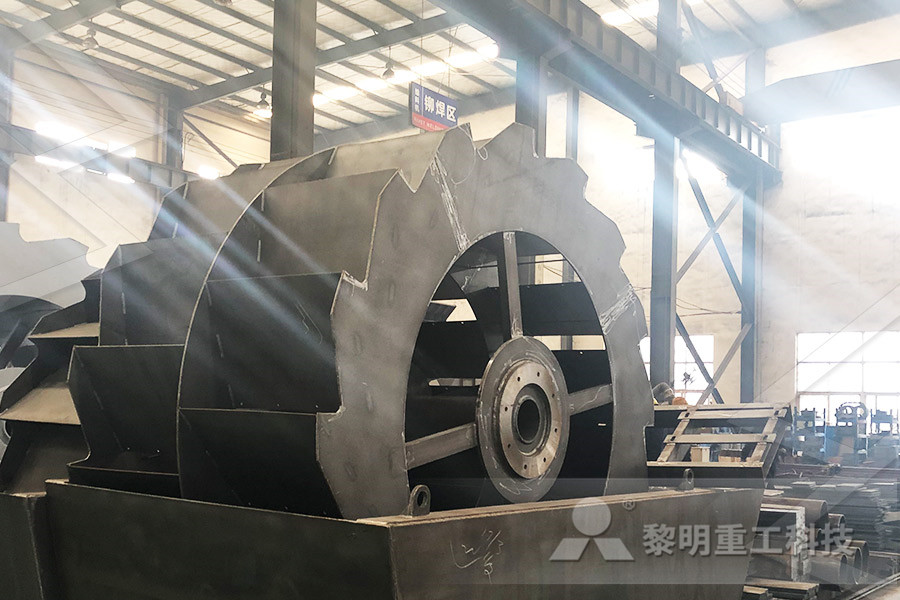

A general chromite ore mining process consists of two sections: 1 Comminution Chrome lump ore must be crushed and ground into powder due to medium and fine Most chrome ore must be processed by the chrome ore processing plants the mainly chrome ore beneficiation method is gravity separation So the mainly used chrome ore concentrating equipments are ore washbox Chrome Ore, Chrome Recovery, Chrome Chrome Ore Process The mainly process of chrome ore processing is gravity separation Sometimes low intensity magnetic separation or highintensity magnetic separation will Chrome Ore Process Plant JXSC Mineral

How to process Chrome ore with Mining

Then go to chrome ore separation machine and concentration machine( chrome ore shaking table, chrome ore spiral chute, chrome ore jig separator,ect) Below Some mine site pictures of our 5TPH capacity The beneficiation process of chrome ore For the processing of chrome ore, there are various methods such as gravity separation, flotation, magnetic separation, etc Chromite Processing Methods,beneficiation process of After this first firing, the resultant product is crushed, ground, mixed with chrome ore, and fired for a second time at a lower temperature Further improvement occurred when both Chrome Ore an overview ScienceDirect Topics

Chrome Mining Process

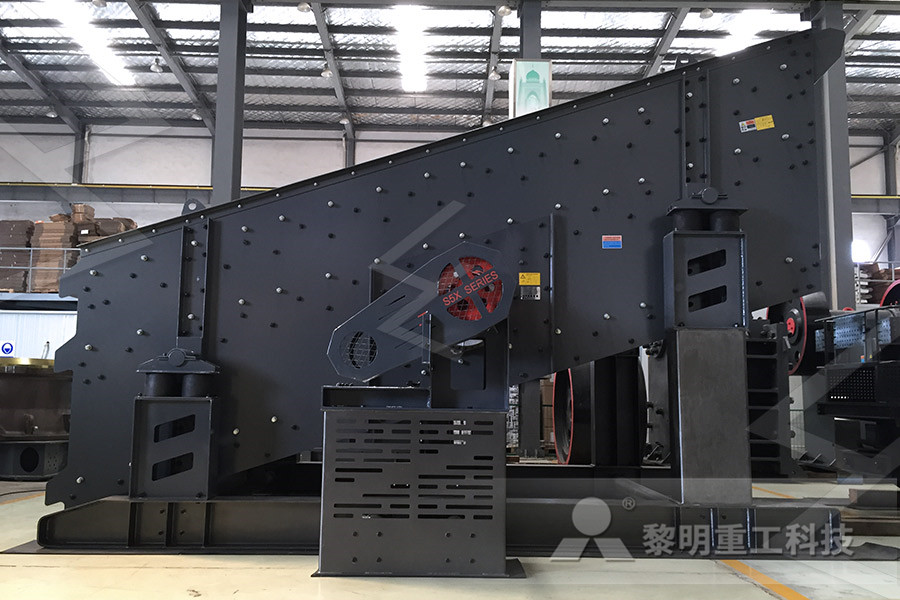

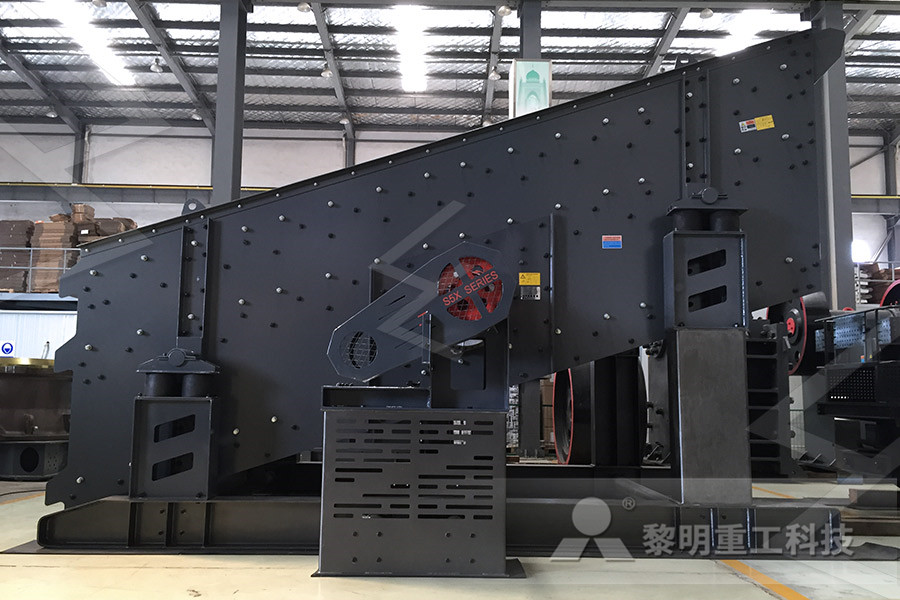

2 天前 Process: First use hopper and vibration screen feeding stone chrome to preliminary crusher, then to fine crusher, Then use a belt to a hopper, underside the hopper has a In this article, the performance of an operating chromite beneficiation plant is evaluated based on mineralogical characterization of samples from around the circuit Process optimization of a chrome ore gravity Before it is fed to the 4’x 8′ Peripheral Discharge Rod Mill, the minus ¼” chrome ore is removed from the grinding circuit by means of a 4’x 12′ Dillon Vibrating Screen This minus ¼” product is then ready for Chromite Beneficiation Process Mineral

Chrome Ore, Chrome Recovery, Chrome

Process Description For chrome processing technology, there are gravity separation, flotation, magnetic separation and other methods Xinhai will determine the final processing technology according to the ore 2 天前 process: first use hopper and vibration screen feeding stone chrome to preliminary crusher, then to fine crusher, then use a belt to a hopper, underside the hopper has a feeder, feeder 020mm size to ball mill, ball mill working together with a spiral classifier, then get 01mm size to shaking table, shaking table also has twostage, one for Chrome Mining Process Before it is fed to the 4’x 8′ Peripheral Discharge Rod Mill, the minus ¼” chrome ore is removed from the grinding circuit by means of a 4’x 12′ Dillon Vibrating Screen This minus ¼” product is then ready for Chromite Beneficiation Process Mineral

Production process of chrome ore abcsoleilbe

Production Process Ferrochrome (FeCr) is a corrosionresistant alloy of chrome and iron containing between 50 and 70 chrome Ferrochrome production is essentially a carbothermic reduction operation taking place at high temperatures Cr Ore an oxide of chromium and iron is reduced by coal and coke to form the ironchromium alloyA conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: Communition (for preparing the material for the subsequent unit operations) ConcentrationProcess optimization of a chrome ore gravity Keramat and Garmsiri (2018) utilized the Slon magnetic separator to concentrate finegrained (180 µm) chromite ores with a Cr2O3 = 35%, that obtained concentrate with a grade of about 42% andChrome ore beneficiation challenges

Smelting chrome ore ScienceDirect

SMELTING REACTIONS In the smelting process the electric furnace is charged with the chrome ore, a carbon reducing agent, and a flux, usually quartz Reaction of these materials produces slag and liquid ferrochrome, which are withdrawn from the hearth, and carbon monoxide, which rises through the descending charge Ore is a sandlike mineral that is mined from a ore deposit or is made from lean ore by beneficiation Metallurgical grade chrome ore is mainly used to smelt various ferrochrome alloys The chromium ore used for ferroalloy smelting is divided into several grades according to different smelting purposes Metallurgical grade chromite can also be What is the use of metallurgical grade chrome oreChromite is an oxide mineral composed of chromium, iron, and oxygen (FeCr 2 O 4 ) It is dark gray to black in color with a metallic to submetallic luster and a high specific gravity It occurs in basic and ultrabasic Chromite: The only mineral ore of chromium

Five Chrome Extraction Process to Teach you the Chromite

At present, the common chrome extraction processes mainly include gravity separation, magnetic separation, electric separation, flotation, gravitymagnetic separation process Below, let’s takeChrome ore sand is obtained from chromite (chrome iron ore), which is processed into chromite sand with the aid of liquid binders after extraction from natural deposits EKCAG: Procurement and logistics of chrome ore (chromite) About two thirds Chrome ore EKCAGa process for extracting chromium in the form of a chromate from ore or concentrate by the suspension oxidation thereof to the chromate state which comprises suspending finely crushed ore or concentrate containing the chromium in a molten liquid bed of an alkali metal salt in the ratio of 1 part by weight of ore to 5 to 20 parts by weight of salt Production process of chrome ore abcsoleilbe

process of chrome ore

Chrome Ore Beneficiation Technical ProcessBAILING® Machinery Chrome Ore Beneficiation Technical Process Conspectus of Mineral Processing Chromite (FeCr2O4), specific gravity 4346, hardness 5575, is the only useful mineral for chrome ore beneficiation, which also can be used as high grade refractory Get Price Get Quote WhatsApp Chrome ore beneficiation process mainly includes gravity separation process, magnetic separation process, flotation process, combined separation process, chemical separation process and so on Usually, the industry adopts single gravity separation process, single magnetic separation process, and gravity separation magnetic separation processQuestions about Chrome Ore Beneficiation Miningpedia The IMSBC Code part 17 has the following definition: Concentrates means materials obtained from a natural ore by a process of enrichment or beneficiation by physical or chemical separation and removal of unwanted constituents However, cargoes with “Concentrate” in the given Bulk Cargo Shipping Names (BCSN) listed within the IMSBC Code are Carriage of Chrome Ore Concentrate westpandi

chromeprocesses Chrome Developers

onUpdatedWithMemory chromeprocessesonUpdatedWithMemoryaddListener ( callback: function, ) Fired each time the Task Manager updates its process statistics, providing the dictionary of updated Process objects, indexed by process ID Identical to onUpdate, with the addition of memory usage details included in each Process objectContribute to jidafang2022/en development by creating an account on GitHuben/chrome ore crushing processmd at main Cost analysis of chrome ore reduction is one of the important issues facing ferrochrome producers in today’s competitive environment Much of this depends on quality and various ratios in the actual ore The latter can have a direct bearing on electricity consumption and optimum efficiency of the furnacesEFFECT OF CHROME ORE QUALITY ON FERROCHROME

Effect of Chrome Ore Quality on Ferrochrome

ore has positive correlation with Cr2O3, the MgO/Al2O3 ratio increases with reduction in Cr2O3 content Thus, as the Cr2O3 and Al2O3 decreases, the MgO increases Table 1 Chemical composition of chrome ore used Item Main ore, mass% Ore 2, mass% Ore 3, mass% Cr2O3 40 – 52 33 – 41 34 – 38 Cr/Fe Ratio 28 – 35 23 – 25 23 – 25

Any of your enquiry will be highly appreciated.

Enquiry Now