pelletizing iron ore hematite

2022-06-19T16:06:40+00:00

Iron Ore Pelletizing Perantech

Iron Ore Pelletizing As one of the main components of ironmaking equipment such as blast furnaces, iron ore pellets affect the efficiency of these processes In the final step, the Dec 31, 2015 In the iron oreorganic system, cohesion and adhesion are the main forces that exist inside the pellet [32, 33], capillary forces are almost (PDF) Iron ore pelletization ResearchGateJul 11, 2018 The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore Iron Ore Pelletizing Process: An Overview IntechOpen

The Study of Pelletizing of Mixed Hematite and Magnetite

Jan 11, 2019 Hematite ore pellets require a higher induration temperature (>1300 ºC) than magnetite ore pellet because, in magnetite ore, Fe 3 O 4 Nov 26, 2014 In case of pelletization of the magnetite ores, when a pellet starts to oxidize, a shell of hematite is formed while the pellet core is still magnetite Thermal volume changes in Iron Ore Pellets and Pelletization Process – IspatGuruWith Hematite Iron Ore GENERAL: 12MTPA pellet plant adopts gratingkilncooler technology, The main technology equipment have dryer,highpressure roller mill,mixing machine,disc Pelletization Plant With Hematite Iron Ore machineto

Iron Ore Pellets Market to reach $90 Bn by 2032, says

16 hours ago Hematite is projected to account for a significant share of the iron ore pellets market revenues through 2032 as it is present in abundance across the globe and has 70% Hematite and magnetite iron ore pelletizing damp mill Hematite and magnetite iron ore pelletizing damp mill FOB Price 10000 USD / Sets Get Latest Price MOQ: 1 Hematite and magnetite iron ore pelletizing damp millMar 04, 2015 Pelletization of hematite ore requires high fineness and very high induration temperature (~1325 °C) owing to its poor diffusion bonding unlike magnetite ore Further, high Effect of Blaine Fineness on the Quality of Hematite Iron

Iron Ore Pelletization FEECO International Inc

Iron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores This process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the iron oreIron Ore Pelletizing As one of the main components of ironmaking equipment such as blast furnaces, iron ore pellets affect the efficiency of these processes In the final step, the pellets are baked, which binds the hematite particles There are different systems for this, such as vertical shaft kiln, straight/traveling grate system, or Iron Ore Pelletizing PerantechExpert Answers: Pelletizing of iron ore Iron ore pellets are spheres of typically 6–16 mm (024–063 in) to be used as raw material for blast furnaces The process of What is the most common ore of iron? Hematite and magnetite are by far the most common types of ore Pure magnetite contains 724 percent iron, hematite 699 percent For iron ore pellets? Explained by FAQ Blog

Iron Ore Pellets Market to reach $90 Bn by 2032, says

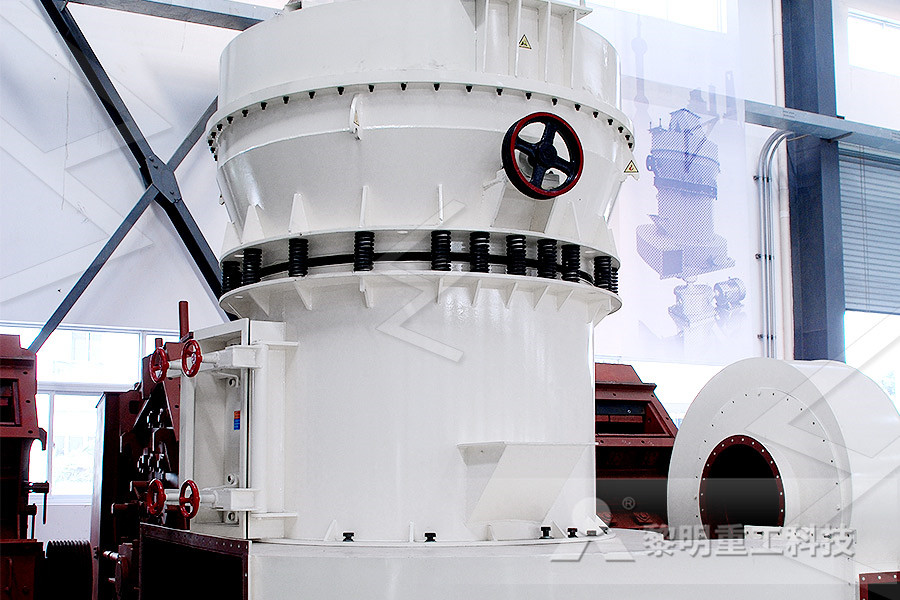

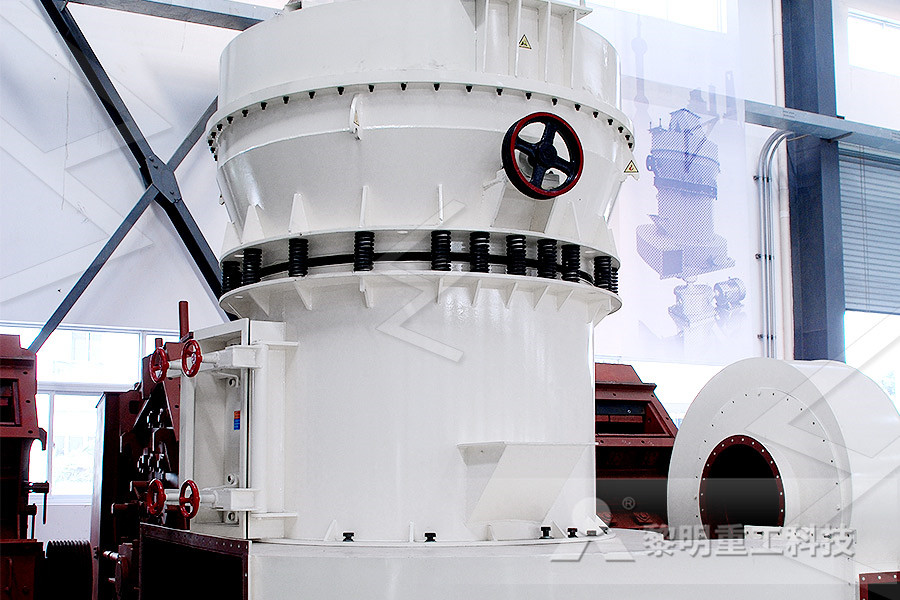

16 hours ago Hematite is projected to account for a significant share of the iron ore pellets market revenues through 2032 as it is present in abundance across the globe and has 70% iron content InWith Hematite Iron Ore GENERAL: 12MTPA pellet plant adopts gratingkilncooler technology, The main technology equipment have dryer,highpressure roller mill,mixing machine,disc pelletizer,travelling grate,rotary kiln,annular cooler,dust extractor and fans Plant Systems: The main production system of newbuild pellet production line include:Pelletization Plant With Hematite Iron Ore machinetoPelletizing of Iron Ores Kurt Meyer Free ebook download as PDF File (pdf), Text File (txt) or read book online for free This book is a reference in the knowledge of iron ore pelletizing He deals with various aspects from raw Pelletizing of Iron Ores Kurt Meyer PDF Iron Ore

Pelletizing Iron Orehematite hadooptrainingchennai

The temperature in iron ore pelletizing process is as high as 1 3001 320 degrees C, so that a significant amount of liquid slag forms in the pellets and more of the limonite was converted to hematite The ore hematite iron ore crusher for sale in brazil In brazilian iron ore hematite In Malawi In Malawi M View Details Send EnquiryAbstract In this study the separation possibility of gangue minerals from a low grade magnetite ore with 45% Fe from an iron ore deposit located near ErzincanTurkey was investigatedLaboratory size pelletizing disc to produce iron ore pellets16 hours ago Selbyville, Delaware, Nov 15, 2022 (GLOBE NEWSWIRE) According to a new research report by Global Market Insights Inc, the global Iron Ore Pellets Market is expected to be valued at around USD Iron Ore Pellets Market to reach $90 Bn by 2032, says Global

pelletizing iron ore hematite

Dec 28, 2015 Iron ore products Pellets LKABs iron ore pellets are made from magnetite and have high iron content, around 67 percent These two factors give a lower environmental impact both during the pelletizing process and during steelmaking, than competing pellets and sintered hematite finesJan 01, 2020 Hematite iron ore fines from Barbil region of Odisha having 64% Fe are used for pellets preparation The particle size distribution of the iron ore fines having the specific gravity 48 with Blaine no2672 cm 2 /gm is used as given in Table 1The anthracite coal is used to maintain uniform temperature throughout the pellets during indurationEffect of additives concentration on pelletization of high grade hematitepelletizing iron ore hematite T11:11:23+00:00 Iron Ore Pellets and Pelletization Process – IspatGuru 26/11/2014 As for the firing of hematite iron ores, more heat is required to be supplied from external sources due to the absence of the following exothermic reaction of oxidation of magnetite 4FeO + O2 = 2Fe2O3 The energy pelletizing iron ore hematite

USA Pelletizing of iron ore Google Patents

indurated iron oxide pellets are made by an improved process comprising oxidizing green pellets formed from finely divided iron oxide solids and finely divided reduced iron solids the amount of iron oxide and reduced iron is proportioned so that oxidation of the green pellets will generate sufficient heat to sustain the oxidation and induration processIron Ore Pelletizing As one of the main components of ironmaking equipment such as blast furnaces, iron ore pellets affect the efficiency of these processes In the final step, the pellets are baked, which binds the hematite particles There are different systems for this, such as vertical shaft kiln, straight/traveling grate system, or Iron Ore Pelletizing PerantechExpert Answers: Pelletizing of iron ore Iron ore pellets are spheres of typically 6–16 mm (024–063 in) to be used as raw material for blast furnaces The process of What is the most common ore of iron? Hematite and magnetite are by far the most common types of ore Pure magnetite contains 724 percent iron, hematite 699 percent For iron ore pellets? Explained by FAQ Blog

Pelletizing of Iron Ores Kurt Meyer PDF Iron Ore

Pelletizing of Iron Ores Kurt Meyer Free ebook download as PDF File (pdf), Text File (txt) or read book online for free This book is a reference in the knowledge of iron ore pelletizing He deals with various aspects from raw With Hematite Iron Ore GENERAL: 12MTPA pellet plant adopts gratingkilncooler technology, The main technology equipment have dryer,highpressure roller mill,mixing machine,disc pelletizer,travelling grate,rotary kiln,annular cooler,dust extractor and fans Plant Systems: The main production system of newbuild pellet production line include:Pelletization Plant With Hematite Iron Ore machineto16 hours ago Hematite is projected to account for a significant share of the iron ore pellets market revenues through 2032 as it is present in abundance across the globe and has 70% iron contentIron Ore Pellets Market to reach $90 Bn by 2032, says

Effect of additives concentration on pelletization of high grade hematite

Jan 01, 2020 Hematite iron ore fines from Barbil region of Odisha having 64% Fe are used for pellets preparation The particle size distribution of the iron ore fines having the specific gravity 48 with Blaine no2672 cm2 /gm is used as given in Table 1 The anthracite coal is used to maintain uniform temperature throughout the pellets during indurationJun 16, 2022 Some factors have contributed to this fact like as: depletion of highgrade iron ore reserves, expansion of Chinese steel production, growth of direct reduction, better performance of pellets in EVOLUTION AND GROWTH OF IRON ORE PELLETIZING16 hours ago Some of the major players operating in the iron ore pellets industry are Evraz, Anglo American, BHP Billiton, Bahrain Steel, ClevelandCliffs Inc, FERREXPO, and Jindal SAW LtdSelbyville Iron Ore Pellets Market to reach $90 Bn by 2032, says Global

pelletizing iron ore hematite

Dec 28, 2015 Iron ore products Pellets LKABs iron ore pellets are made from magnetite and have high iron content, around 67 percent These two factors give a lower environmental impact both during the pelletizing process and during steelmaking, than pelletizing iron ore hematite T11:11:23+00:00 Iron Ore Pellets and Pelletization Process – IspatGuru 26/11/2014 As for the firing of hematite iron ores, more heat is required to be supplied from external sources due to the absence of the following exothermic reaction of oxidation of magnetite 4FeO + O2 = 2Fe2O3 The energy pelletizing iron ore hematiteindurated iron oxide pellets are made by an improved process comprising oxidizing green pellets formed from finely divided iron oxide solids and finely divided reduced iron solids the amount of iron oxide and reduced iron is proportioned so that oxidation of the green pellets will generate sufficient heat to sustain the oxidation and induration processUSA Pelletizing of iron ore Google Patents

The Study of Pelletizing of Mixed Hematite and Magnetite

Pelletizing of magnetite and hematite ores with different mixing ratios have been studied [4, 69] Some problematic ore sources can be used by this method and the firing operation can be done at standard or expected temperatures In this study two iron oxide sources, magnetite and hematite ore concentrates were used in pelletizing testsAbstract In this study the separation possibility of gangue minerals from a low grade magnetite ore with 45% Fe from an iron ore deposit located near ErzincanTurkey was investigatedLaboratory size pelletizing disc to produce iron ore pelletsUSA US7008A USA USA US A US A US A US 7008 A US7008 A US 7008A US A US A US A US A US A US A Authority US United States Prior art keywords iron ore sintering pellet pellets concentrates Prior art date Legal status (The legal status is an USA Pelletizing of iron ore for sintering Google Patents

Any of your enquiry will be highly appreciated.

Enquiry Now