investigation of the effect of intensive ball milling in a

2023-01-26T17:01:56+00:00

Investigation of the effect of intensive milling in a

Abstract The kinetics of thermal decomposition of basic nickel carbonate NiCO 3 Ni (OH) 2 nH 2 O and the effect of intensive milling in a planetary ball mill on its parameters, have been investigated The values of the reaction heat and of the activation The kinetics of thermal decomposition of cadmium carbonate CdCO3 and basic zinc carbonate ZnCO3?nZn(OH)2 and the effect of intensive milling in a planetary ball mill on Investigation of the effect of intensive ball milling in a Made available by US Department of Energy Office of Scientific and Technical Information Investigation of the effect of intensive milling in a

Investigation of the effect of intensive milling in a

The values of the reaction heat and of the activation energy of thermal decomposition have been determined Investigations of the thermal decomposition of the products of ball Abstract The kinetics of thermal decomposition of cadmium carbonate CdCO3 and basic zinc carbonate ZnCO3nZn (OH)2 and the effect of intensive milling in a Investigation of the effect of intensive ball milling in a The kinetics of thermal decomposition of cadmium carbonate CdCO 3 and basic zinc carbonate ZnCO 3 nZn(OH) 2 and the effect of intensive milling in a planetary ball mill Investigation of the effect of intensive ball milling in a

Investigation of the effect of intensive milling in a

The kinetics of thermal decomposition of basic nickel carbonate NiCO 3 Ni(OH) 2 nH 2 O and the effect of intensive milling in a planetary ball mill on its parameters, have been The kinetics of thermal decomposition of cadmium carbonate CdCO 3 and basic zinc carbonate ZnCO 3 nZn(OH) 2 and the effect of intensive milling in a planetary ball mill Investigation of the effect of intensive ball milling in a This study presents a novel derived theoretical model for MAassisted leaching in investigating the effects of ball mill parameters on the particle sizes (retained and Effect of Ball Mill Parameters’ Variation on the Particles of

Effects of shorttime vibratory ball milling on the shape of

Studies of the effect of ball milling on the ultrastructure of wood cell walls, by Maurer and Fengel , showed that the compound middle lamellae and the cell corners are Investigation of the effect of intensive milling in a planetary ball mill on the thermal decomposition of basic nickel carbonate May 2011 Journal of Physics Conference Series 289(1):Investigation of the effect of intensive milling in a In machining of Inconel 718, various difficulties such as increased tool wear and poor machined surface quality are frequently encountered due to its high temperature strength and poor thermal properties This work considers the effect of number of passes and the machining environment on the machined surface quality in ball end milling of Experimental Investigation into the Effect of Ball End

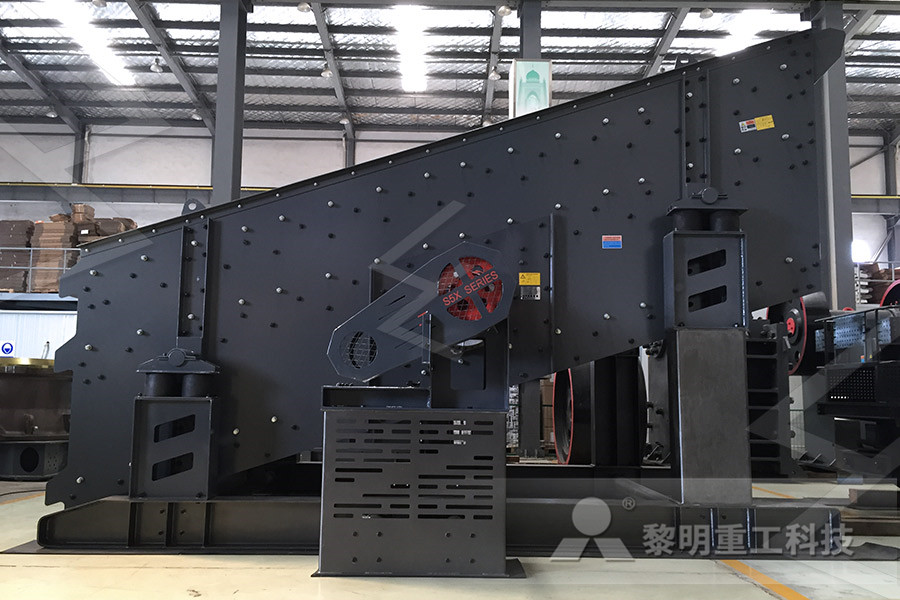

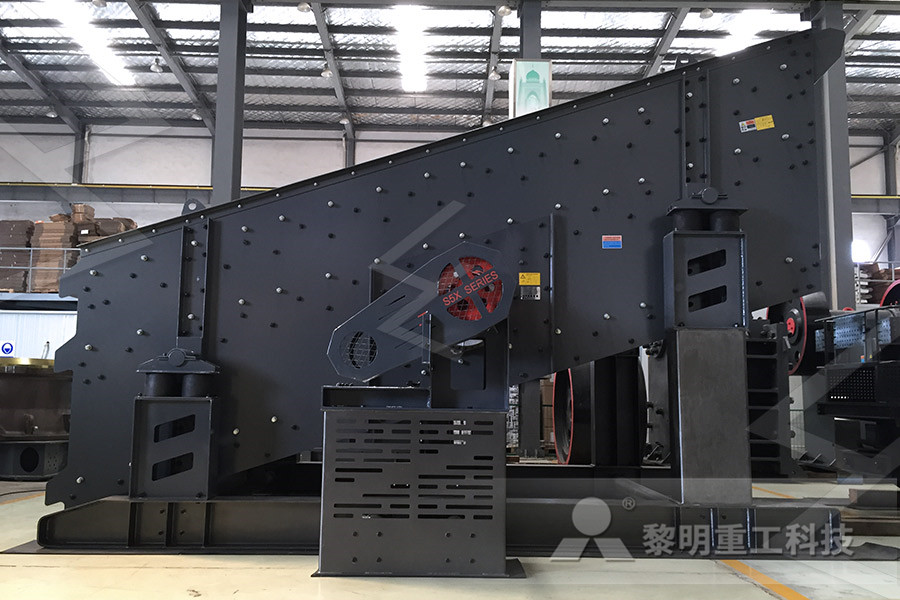

Investigation of the effect of industrial ball mill liner type

The mill shell liner type, rotation speed and the amount of its loading are the key factors influencing the charge behavior, consequently the comminution mechanism In this paper, milling operation of industrial ball mills using Discrete Element Method (DEM) is investigated First, an industrial scale ball mill with a Smooth liner type is simulated Then, by changing The kinetics of thermal decomposition of basic nickel carbonate NiCO 3 Ni(OH) 2 nH 2 O and the effect of intensive milling in a planetary ball mill on its parameters, have been investigated The values of the reaction heat and of the acInvestigation of the effect of intensive milling in a The geometry of 5axis milling operations can be modelled using three coordinate systems as shown in Fig 1The first one is a fixed coordinate system, MCS, formed by the (X), (Y) and (Z) axes of the machine toolThe second coordinate system is the process coordinate system, FCN, consisting of feed (F), crossfeed (C) and surface Investigation of lead and tilt angle effects in 5axis ball

Ball Milling Intensive facetofacepl

The Effect Of Grinding Time On The Specific wet grinding and/or the use of small milling balls (eg stirring ball mills) is favorable for the generation of new and additional surfaces, while, dry grinding and/or the use of larger milling balls (eg vibratory and/or planetary mills) brings about intensive bulk disorder in the milled material 11 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a laboratoryscale mill The mill was simulated at different critical speeds with different mill fillings In total, 165 scenarios were simulatedEffects of Ball Size Distribution and Mill Speed and Their Investigation of the effect of industrial ball mill liner investigated First, an industrial scale ball mill with a Smooth liner type is simulated Then, by changing liner type, ie Wave, Rib, Ship lap, Lorain, Osborn, and Step liners, six other independent simulations are performed Effects of mill shell liner type on charge shoulder, toe, +[investigated the effect of ball milling on the]

investigated the effect of ball milling on the

The kinetics of thermal decomposition of basic nickel carbonate NiCO 3 Ni(OH) 2 nH 2 O and the effect of intensive milling in a planetary ball mill on its parameters, have been investigated The values of the reaction heat and of the activation energy of thermal decomposition have been determinedThe effect of ball mill on the morphological and structural features of cellulose has been described by Okajima and coworkers 20 They treated microcrystalline cellulose derived from cotton linters in a planetary ball mill at 200 rpm for 4–8 Ball milling: a green technology for the Based on the isolation yield and structure features, milling time with 3 and 7 h were sufficient to isolate the representative lignin (with yield over 30%) in the cell wall of bamboo residues and poplar sawdust, respectively, while more than 7 h should be carried out to isolate the representative lignin in larch sawdustThe Effect of Ball Milling Time on the Isolation of Lignin in

Ball milling: a green technology for the

The effect of ball mill on the morphological and structural features of cellulose has been described by Okajima and coworkers20 They treated microcrystalline cellulose derived from cotton linters in a planetary ball mill at 200 rpm for 4–8 Drastic temperature rise at rapid ball milling leads to increase in plasticity and local melting of treated powder particles that result in their adherence to the surfaces of milling balls and mill cylinder walls Mass of aluminum powder adhered to the ball surface is proportional to the total surface area of all balls loaded in millInvestigation of Influence of Input Energy during Ball Results revealed that the ball milling process and the refinement of tungsten particle and grain can be largely influenced by these two parameters The milling efficiency was found to be highest with the milling speed of 700 rpm and additive amounts of 8% PCAMetals Free FullText Effect of Ball Milling Parameters on

Effects of Ball Size Distribution and Mill Speed and Their

A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a laboratoryscale mill The mill was simulated at different critical speeds with different mill fillings In total, 165 scenarios were simulated For example, Turner (1979) has demonstrated an overall increase in capacity of almost 800 percent by ball addition to an ore of extreme difficulty to grind in the autogenous mode, and attributes the increased efficiency to both Factors Affecting Ball Mill Grinding Efficiency Effect of the milling time on the structure, morphology, and electromagnetic parameters of Fe 3 O 4 were studied, and the absorption properties and mechanism of Fe 3 O 4, for different milling times were Effect of Ball Milling on the Absorption

Investigation of cutting force behaviour considering the

Investigation of cutting force behaviour considering the effect of cutting edge radius in the microscale milling of AISI 1045 steel IS Kang, JS Kim, YW Seo, 2011 Reviewers Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture Impact Factor: 2759 / 5Year Impact Factor: 2573 JOURNAL HOMEPAGE According to the MC hotspot theory, during milling, when a ball hits another ball or the jar wall compressing a small amount of powder, on the contact surface the temperature rises up toDioxins reformation and destruction in secondary copper

Any of your enquiry will be highly appreciated.

Enquiry Now