maintenance system used in line crusher

2020-10-16T20:10:26+00:00

Maintenance of Cone Crusher Hydraulic System

Nov 03, 2022 Cone crusher is widely used in mine production due to its high crushing efficiency, low maintenance cost and large output capacity Cone crushers are divided Cone crusher hydraulic system routine maintenance precautions cone crusher hydraulic system is mainly used to ensure the normal operation of equipment, maintenance system used in line crusher Maintenance System Used In Line Crusher In order to monitor crusher performance CANTY provides Industrial SolidSier or 3D Rocksier image analysis systems which maintenance system used in line crusher mamluszczycepl

maintenance system used in li ne crusher pappadumscoza

8 Maintenance Notice Templates A maintenance notice is usually a formal document to remind or announce designated recipients about matters relating to property or Development of Dual Stone Crusher System for Slurry Tunnel The proposed Thomson East Coast Line TEL is a 43km long fully The roller crusher system Figure 4 1 also maintenance system used in li ne crusher studio3tpl Portable Limestone Crushing Line Crusher Cone Crusher Line In Indonesia Malaysia 300TPH Impact Crushing Plant Specifications of Portable Crusher Maintenance System Portable In Line Crusher lerepitfr

maintenance system used in line crusher ladresseloungebe

When the pilot line in a pilottoclose valve is pressurized, the check valve is closed, blocking flow in both directions Shutoff valves Shutoff valves are used to isolate one part of a Operations and Maintenance Manual Miller Group A crusher and screening plant operates onsite Aggregate is transported from the active face to the crusher where it is maintenance system used in line crusher fitnessklubcentrumplFri Maintenance System Used In Line Crusher fri maintenance system used in line crusher 8 Construction Working and Maintenance of Crushers for Crushing Bulk maintenance system used in line crusher

Crusher Maintenance Services Crusher Maintenance System

Quality Maintenance to Ensure Safety and Performance Clients of DMMeng have been reaping the benefits of their custom crusher maintenance system for over 30 years, ensuring their crushing machinery is treated to the very best upkeep that results in maximum performance, fewer faults and minimal unwanted down timeNov 03, 2022 Cone crusher is widely used in mine production due to its high crushing efficiency, low maintenance cost and large output capacity Cone crushers are divided into spring cone crushers and Maintenance of Cone Crusher Hydraulic SystemFor more details, contact: parts@kemperequipment Other crusher maintenance priorities It’s true that the way you operate your crushers will determine how often maintenance is needed, both in terms of regular Maintenance of Material Handling Equipment

Avoid Unplanned Downtime: 5 Crusher

Feb 25, 2019 There are three approaches to maintenance: reactive, preventative and predictive Reactive is repairing something that has failed Preventative maintenance is often viewed as unnecessary but 8 Maintenance Notice Templates A maintenance notice is usually a formal document to remind or announce designated recipients about matters relating to property or equipment repair and check up Often a maintenance notice template is used so as to be consistent with format and structure of the information to be related and made known of 28 FREE maintenance system used in li ne crusher pappadumscozaNov 30, 2015 The Computerized Maintenance Management System (CMMS) is a tool used to collect field data and convert it into useful information such that maintenance can determine work needs, control Maintenance Management Systems Procedures

maintenance system used in li ne crusher studio3tpl

Development of Dual Stone Crusher System for Slurry Tunnel The proposed Thomson East Coast Line TEL is a 43km long fully The roller crusher system Figure 4 1 also known as the drum crusher is used to break However maintenance of the dual crusher system has clocked 14 hours out ofOperations and Maintenance Manual Miller Group A crusher and screening plant operates onsite Aggregate is transported from the active face to the crusher where it is mechanically processed through a series of crushers and screen siz The production line equipment configuration is primarily based on stone specification and final product maintenance system used in line crusher fitnessklubcentrumplRock, Concrete, Aggregate Crushers Stedman Machine builds highquality aggregate stone crushing equipment for limestone, sand, and gravel that are used , Rock Concrete Crushers , maintenance maintenance system used in limestone crusher

maintenance system used in line crusher

Fri Maintenance System Used In Line Crusher fri maintenance system used in line crusher 8 Construction Working and Maintenance of Crushers for Crushing Bulk Materials Gyratory Crushers Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher Apr 16, 2014 MPF series impact crusher has simple structure, high strength of wearresistant parts, and convenient maintenance It is suitable for crushing various coarse, medium and fine materials with compressive strength not higher than 350MPa It is widely used in various ore crushing, railways, and highwaysMaintenance System Used In Limestone Crusher KeracoonEasy Maintenance jaw crushing production line supplier mining use complete details about easy maintenance jaw crusher,mining use jaw crusher,stone crusher jaw,stone crusher jaw,mining use jaw crusher,easy maintenance jaw crusher from crusher supplier or manufacturer zhejiang zhekuang heavy industries china jaw crusher pe400x600, view maintenance system used in line crusher stalhoogeelmtenl

used in line crusher

Maintenance system used in line crusher construction waste crusher construction waste refers to the construction construction units or individuals to construct lay or demolish all kinds of buildings structures and pipe networks etc and generate the spoil spoil waste residual mud and other wastes generated during the repairing processDuring use, it can avoid many unnecessary wear problems and reduce the trouble of frequently changing parts 8 notes of jaw crusher routine maintenance 1 Check the heat of the bearing The temperature of rolling bearings doesn’t exceed 70 ° C If exceeds the specified temperature, it must stop and immediately check and troubleshoot 25 Types Of Stone Crushers Application and Maintenance JXSC Rock CrusherCustom Crusher Maintenance Services One of the most important pieces of machinery on any mining site is the crusher, responsible for breaking down larger rocks excavated from the ground into smaller rocks, rock dust or gravel There are numerous types of crushers, including jaw, gyratory, cone crusher and impact crusherCrusher Maintenance Services Crusher Maintenance System

Maintenance of Cone Crusher Hydraulic System

Nov 03, 2022 Cone crusher is widely used in mine production due to its high crushing efficiency, low maintenance cost and large output capacity Cone crushers are divided into spring cone crushers and Feb 01, 2014 To prevent crusher damage, downtime and difficult maintenance procedures, the hydraulic overload relief system opens the crusher when internal forces become too high, protecting the unit against costly component failure After relief, the system automatically returns the crusher to the previous setting for continued crushingJaw crusher maintenance : Pit QuarryJul 18, 2015 For easy of Operation Maintenance, all Rock Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for oil level, FLOW METERS in the oil lines and/ or VISUAL ACCESS to the discharge point of the oil circuit This is to allow the operator to gauge the oil flow visuallyCrusher Lubrication System Operation Maintenance

maintenance system used in li ne crusher studio3tpl

Development of Dual Stone Crusher System for Slurry Tunnel The proposed Thomson East Coast Line TEL is a 43km long fully The roller crusher system Figure 4 1 also known as the drum crusher is used to break However maintenance of the dual crusher system has clocked 14 hours out ofThe regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts, regular inspection of the hammer, lining plate, bearing temperature, etcMaintenance is a process of doing necessary repairing and service of something to keep that in good working maintenance system used in li ne crusherJun 03, 2020 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries Inside the crusher, a piece of steel, known as the mantle, rotates eccentricallyA Detailed Overview of Cone Crushers and What You Need to

Maintenance System Used In Limestone Crusher

limestone crushers maintenance Us / Print; Sprinkler Systems Maintenance CONSTRUCTION INDUSTRIAL TOOLS EQUIPMENT Todd Cummings used crushing system used crushing system India mining to buy Maintenance System Used In Limestone Crusher Limestone crusher,Limestone hammer crusher,stone production Rock, Concrete, Aggregate Crushers Stedman Machine builds highquality aggregate stone crushing equipment for limestone, sand, and gravel that are used , Rock Concrete Crushers , maintenance maintenance system used in limestone crusherMaintenance system used in line crusher construction waste crusher construction waste refers to the construction construction units or individuals to construct lay or demolish all kinds of buildings structures and pipe networks etc and generate the spoil spoil waste residual mud and other wastes generated during the repairing processused in line crusher

Grease Lubricating System Used in Different Types of Stone Crusher

Oct 23, 2021 Normally, operating an oillubricated crusher with contaminated lubricating oil (old, dirty oil) is a common mistake followed by maintenance people As a thumb rule, operators should use gear lubricants added with extreme pressure additive with a minimum oil viscosity of 22 CST at the bearing operating temperature An important engine part on limestone crusher machine that is part of the initial material or hopper receiver, motor or drive system, material feeding section or feeder Part crushing system or Hammer, and parts box cover which is named by chasing the crusher Limestone Crusher that used in this research described by Figure 41 ContactMaintenance System Used In Limestone CrusherAug 23, 2021 2 Maintenance of the roll crusher (1) Roll crushers require frequent maintenance of the roll surface while in operation (2) Smooth roll crushers are sometimes equipped with grinding wheels on the frame, so that when the roll surface is worn out with pits or grooves, the roll surface can be repaired by grinding on the machine without Roll crusher installation, operation and maintenance

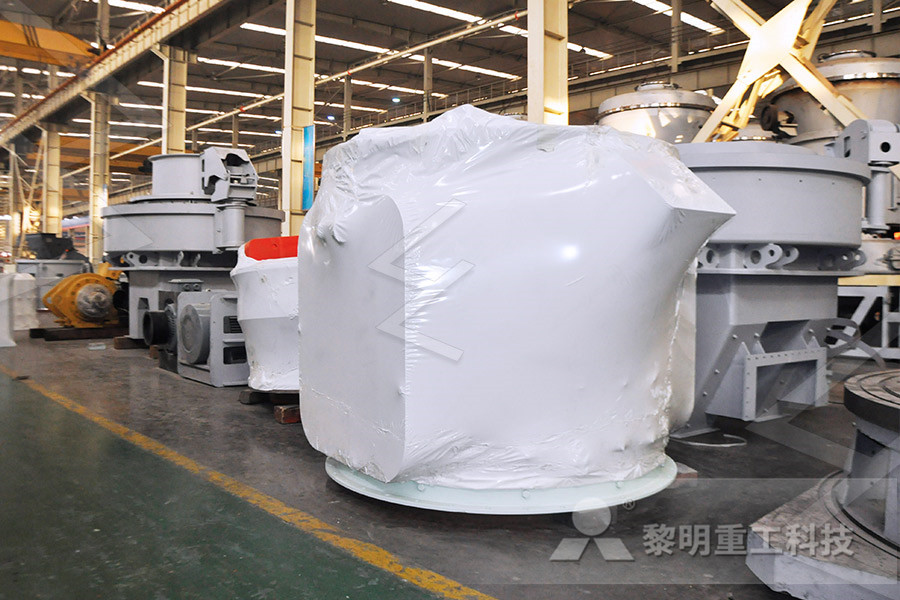

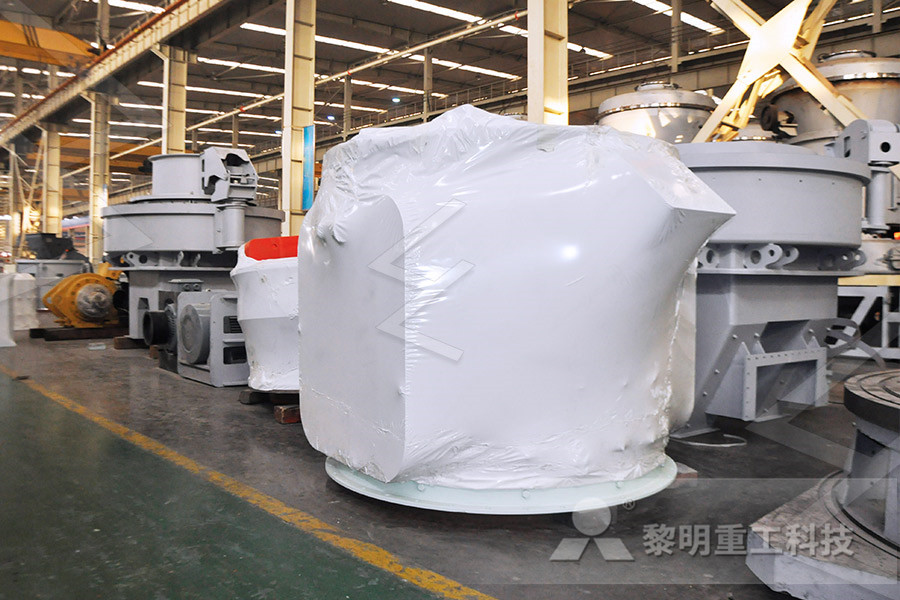

Crushers All crusher types for your reduction needs Outotec

Crushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in mining operations Outotec offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers – optimized for any size reduction need

Any of your enquiry will be highly appreciated.

Enquiry Now