primary roller crusher for mining

2020-03-08T06:03:15+00:00

Primary Crushing Mineral Processing Metallurgy

Feb 26, 2016 A crusher of these dimensions will break 40 tons per hour to 2½in size with a power consumption of 30 hp On the other hand, a 14in Nov 19, 2019 Crushing to the proper size usually occurs in stages because rapid size reduction, accomplished by applying large forces, commonly results in the production of excessive fines How To Select Your Primary Crusher JXSC MiningJun 25, 2021 Tooth Roller Crusher series in Eight Models, with capacity range of (30 –300 Tons/ Hour), applicable for various industries, including Mining, Metallurgy, Coal, Chemical, Biotechnology, Pharmaceutical, Construction, Roll Crusher Double Roller Crusher DOVE

Primary Crusher Mining Crusher Mills, Cone Crusher, Jaw Crushers

Primary crusher – copper mine polymetallic, Download size: 117 MB, Category: Mining industry – Machinery – mechanical, Type: Autocad drawing Mining Aggregates Bodell Construction ERC ® – a new generation of mining equipment thyssenkrupp’s eccentric roll crusher revolutionizes primary crushing The new eccentric roll crusher (ERC ®) boosts efficiency in Eccentric roll crusher ERC® thyssenkrupp Mining TechnologiesJun 23, 2015 1 – fixed cheek with the rotation axis; 2 – a movable cheek; 3, 4 – the eccentric shaft; 5 – rod; 6 – hinged rear bearing spacer cheeks; 7 – spring; 8, 9 – width adjustment mechanism of the discharge gap; 10 – pull the lock Types of Crushers Mineral Processing Metallurgy

Crushing Outotec

Better throughput and faster maintenance +10% crusher throughput and +23% crusher availability Reduce downtime 69% reduction in primary crushing downtime Improve quality At present, the most advanced crusher technology in limestone mine is to use jaw crusher for primary crushing and doublegeared roller crusher for secondary crushing Compared with primary roller crusher for mining abcwogrodzieplCoal Four Roller Crusher – Best Stone Limestone Primary Apr 12 four roller crusher zy mining 4pgm fourroller crusher is a new type of domestic 4pgm fourbeam crusher developed Primary Roller Crusher For Mining In Rus

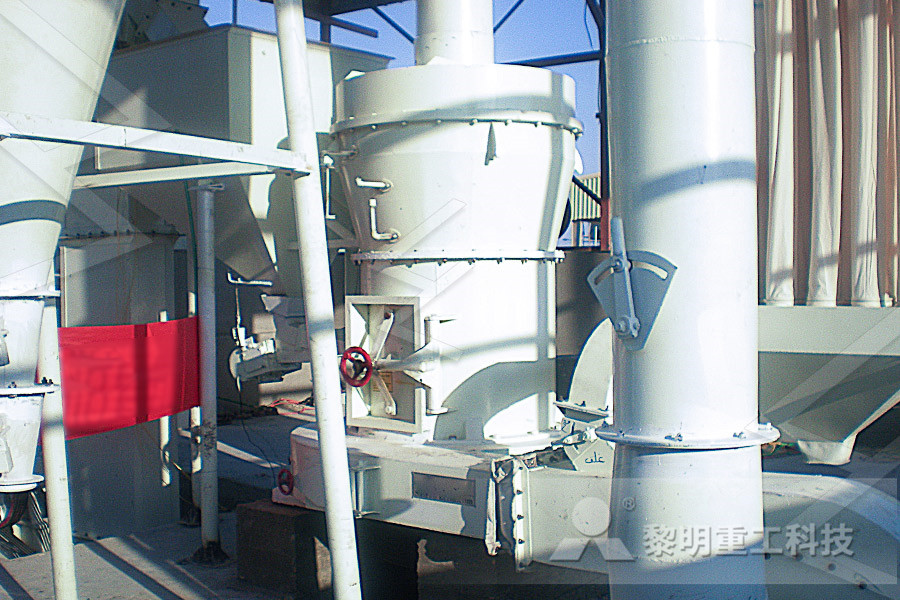

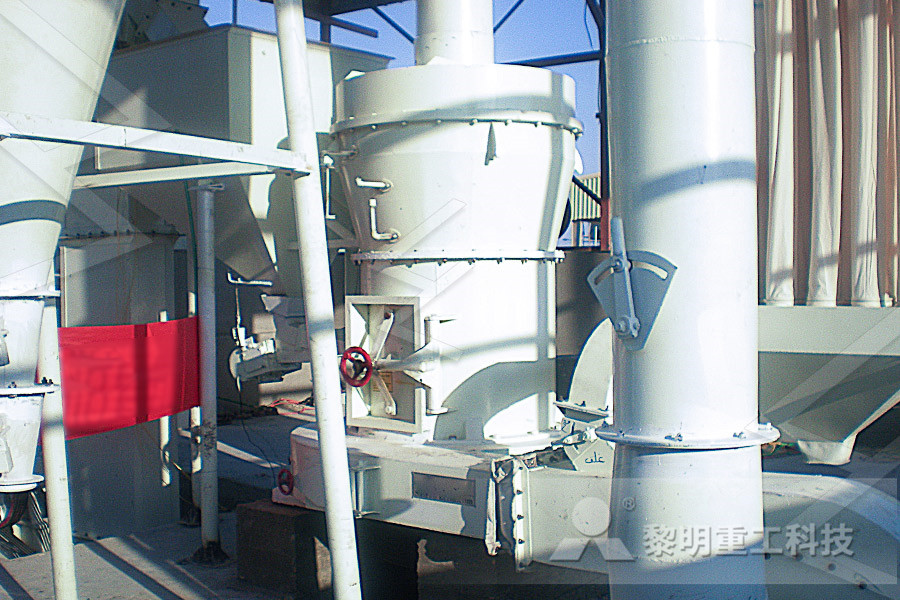

Roller Crusher Mineral Crushing Aggregate

JXSC mining roller double crushers are simple in design and construction, low maintenance cost, low water requirement, reliable performance, less power consumption, less dust, low noise, and the discharging particle size can be Crushing material efficiently in a compact space, the Williams MineSizer Primary Crusher can reduce material as large as 60” in diameter down to 1012” in one pass at high tonnages up to 5002000 tons per hour, while taking up less MineSizer Primary Crusher RunofMine CrusherNov 19, 2019 Crushing to the proper size usually occurs in stages because rapid size reduction, accomplished by applying large forces, commonly results in the production of excessive fines So primary crushers should be solidly built in order to receive large lumps of rock directly from the mines and designed for large tonnage throughputsHow To Select Your Primary Crusher JXSC Mining

Primary Crushing Mineral Processing Metallurgy

Feb 26, 2016 A crusher of these dimensions will break 40 tons per hour to 2½in size with a power consumption of 30 hp On the other hand, a 14in gyratory crusher, working as it should at full capacity, will crush 100 tons per hour to Home Shop Roller crusher roller crusher Symons cone crusher coke, limestone, iron ore, quartz stone and sulfur ore in cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, coal mines MODEL Widely used in the primary crushing process Capacity : 1800 tph, Feeding size 1251000mm,roller crusher BTMARoller crusher or roll crusher feed size: up to 1200 mm in size Roller crusher or roll crusher product sized to: typical products are 100 mm, 50 mm, 38 mm, Aggregate Secondary amp; Tertiary Crusher for sale,Aggregate primary crusher roller marks sizer Mining Quarry Plant

Mining Stone Crushing Equipment Energy Saving Primary Jaw Crusher

We have more than 500 workers, including more than 20 middle and senior technicians Baichy is mainly focus on 4 series products: stone crusher machines, sand making equipment, powder grinding mills, mineral processing equipment and their spare parts Every year, Baichy can turn out 1,000 sets of crushers and 10,000 tons of crusher partsPrimary Crusher Selection amp Design How you select your primary crusher will be based on factors like moisture content maximum rock lump size material density SG abrasion index degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2 000 lbs and are based on crushing limestone weighing loose about 2 Primary Crusher For MiningBetter throughput and faster maintenance +10% crusher throughput and +23% crusher availability Reduce downtime 69% reduction in primary crushing downtime Improve quality 70% increase in the required feed for grinding with optimized crusher liners Reliable, energy efficient crushing solutions for mining applicationsCrushing Outotec

primary roller crusher for mining abcwogrodziepl

At present, the most advanced crusher technology in limestone mine is to use jaw crusher for primary crushing and doublegeared roller crusher for secondary crushing Compared with other secondary crushers, the lump forming rate of the output of the doublegeared roller crusher is increased by 15% 25% (3cm ~ 9cm blocks), which can improve the Growing demand for roller crushers in various sectors such as mining, infrastructure amp building, highways and railways etc are anticipated to drive the global roller crusher market The surge in mining activities in the emerging economies such as Asia Pacific and Latin America have resulted in the increasing usage of roller crushers in the Primary Roller Crusher For Mining monobetplJun 23, 2015 1 – fixed cheek with the rotation axis; 2 – a movable cheek; 3, 4 – the eccentric shaft; 5 – rod; 6 – hinged rear bearing spacer cheeks; 7 – spring; 8, 9 – width adjustment mechanism of the discharge gap; 10 – pull the lock device; 11 – bed; 12 – still cone; 13 – cone moving; 14 – traverse; 15 – hinge suspension rolling cone; 16 – cone of the Types of Crushers Mineral Processing Metallurgy

Primary Roller Crusher For Mining nieuwvelserduinnl

Primary Roller Crusher For Mining 2342 limestone roller crusher products are offered for sale by suppliers on alibabacom of which crusher accounts for 28 mine mill accounts for 3 a wide variety of limestone roller crusher options are available to you there are 793 suppliers who sells [ protected]Jan 07, 2022 A roll crusher is a device that crushes materials with compression It consists of two parallel cylinders that rotate in opposite directions The ore is drawn between the two cylinders and crushed by compression The degree of fineness and the size of the crushed product determine the amount of distance between the two rollsBTMAWhat is the principle of a roller crusher? BTMACrushing material efficiently in a compact space, the Williams MineSizer Primary Crusher can reduce material as large as 60” in diameter down to 1012” in one pass at high tonnages up to 5002000 tons per hour, while taking up less MineSizer Primary Crusher RunofMine Crusher

Roller Crusher Single/Double Roll Crushers JSXC

Rock Roll crusher is fine crusher equipment that similar to the hammer crusher It can crush the compressive strength of less than 160 MPA of materials Medium feed size, and adjustable discharge size With the characteristic of low Dec 23, 2015 Traylor –Fuller Size:–56” x 72” Type: H Toggle Type Double HP:–400 Minimum Jaw Gap : 6” + Birdsboro Size:–56” x 72” TypeC Double Toggle Type 400 HP both with Amsco as the liner supplier The rated capacity Primary Crusher Selection Design Mineral Home Shop Roller crusher roller crusher Symons cone crusher coke, limestone, iron ore, quartz stone and sulfur ore in cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, coal mines MODEL Widely used in the primary crushing process Capacity : 1800 tph, Feeding size 1251000mm,roller crusher BTMA

Primary Crushers Crusher Mills, Cone Crusher, Jaw Crushers

primary crushers,Primary crusher working,maintenance,parts liming Primary crusher Primary crusher used:construction industry,road building,quarrying,mining Get Price TEL:+8621Double Shaft Roll Crusher For Primary Crushing Mining Equipment, Trio Crusher, Crusher manufacturer supplier in China, offering Mining Equipment Primary Stone Jaw Crusher 2436, PE2436 Primary Jaw Crusher for River Stone Crushing, 4 Feet Cone Crusher Klf1160 for Pebble Crushing and so onThe first shaft is a pivoting shaft on the top of the crusher, Primary Roller Crusher For Mining irenelindersnlRoller crusher or roll crusher feed size: up to 1200 mm in size Roller crusher or roll crusher product sized to: typical products are 100 mm, 50 mm, 38 mm, Aggregate Secondary amp; Tertiary Crusher for sale,Aggregate primary crusher roller marks sizer Mining Quarry Plant

Mining Stone Crushing Equipment Energy Saving Primary Jaw Crusher

We have more than 500 workers, including more than 20 middle and senior technicians Baichy is mainly focus on 4 series products: stone crusher machines, sand making equipment, powder grinding mills, mineral processing equipment and their spare parts Every year, Baichy can turn out 1,000 sets of crushers and 10,000 tons of crusher partsPrimary Crusher Selection amp Design How you select your primary crusher will be based on factors like moisture content maximum rock lump size material density SG abrasion index degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2 000 lbs and are based on crushing limestone weighing loose about 2 Primary Crusher For MiningAt present, the most advanced crusher technology in limestone mine is to use jaw crusher for primary crushing and doublegeared roller crusher for secondary crushing Compared with other secondary crushers, the lump forming rate of the output of the doublegeared roller crusher is increased by 15% 25% (3cm ~ 9cm blocks), which can improve the primary roller crusher for mining abcwogrodziepl

Primary Roller Crusher For Mining monobetpl

Growing demand for roller crushers in various sectors such as mining, infrastructure amp building, highways and railways etc are anticipated to drive the global roller crusher market The surge in mining activities in the emerging economies such as Asia Pacific and Latin America have resulted in the increasing usage of roller crushers in the Primary Gyratory Crusher In Cost The primary operating costs of a crusher are parts and labour for maintenance which can vary approximately twice as much as the power for the motor Gyratory crushers generally cost less than 1500 per hour to run while Jaw crushers cost less than 200 including electricity Infomine 2008 getCost Of Primary Crushers Facty Mining Machinery Doubleroller crusher is a primary crusher developed by our company for open pit mines, being matched with crushing equipment in openpit mine semimobile crushing station or selfmovable crushing station which is used for primary crushing of raw coal or overburdening material in openpit mines with output above 10 million tonsprimary roller crusher for mining

BTMAWhat is the principle of a roller crusher? BTMA

Jan 07, 2022 A roll crusher is a device that crushes materials with compression It consists of two parallel cylinders that rotate in opposite directions The ore is drawn between the two cylinders and crushed by compression The degree of fineness and the size of the crushed product determine the amount of distance between the two rolls

Any of your enquiry will be highly appreciated.

Enquiry Now