SKD hematite iron ore beneficiation plant

2022-07-01T12:07:41+00:00

Hematite iron ore beneficiation plant with hematite ore crushing

The hematite ore beneficiation process includes hematite ore crushing, magnetic separation and flotation This passages tells you how to produce iron ore concentrate and the hematite beneficiation equipments Hematite iron ore beneficiation plant Raw Hematite beneficiation technology 083120; 1,751 Views; icon 1; Hematite beneficiation technology With the rapid economic development, the iron ore resources of the Hematite beneficiation technology,processing of iron mineral,ore Forui has HEMATITE iron ore beneficiation machines of crusher, ball mill, rod mill, vibrating screen, classifier, magnetic separator, floatation separator to form a whole Hematite Iron Ore Beneficiation Flow Chart frjig

HEMATITE BENEFICIATION PROCESS, HEMATITE

Overview Hematite is a kind of iron oxide ore, the main component is Fe2O3, it is dark red, the specific gravity is about 526, and it contains 70% Fe and 30% OHematite Ore Beneficiation Flow Chart The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral Hematite Ore Beneficiation Flow Chart ore processingRio Tinto Iron Ore's lowgrade ore beneficiation plant in the Pilbara was commissioned in 1979 Initial engineering, design, and construction were undertaken by KBR (Kellogg Ore Beneficiation an overview ScienceDirect Topics

Hematite Iron Ore Beneficiation Plant machineto

And Equipped with Feeder, Elevator and Conveyor, a full set of hematite iron ore Beneficiation plant can be made It has advantages such as High efficiency, Low Hematite Iron Ore/Magnetite Ore/Gold/Chrom/Copper beneficiation plantFlotation Machine;Magnetic Separator;Wet Ball MillShanghai Mactec Engineering Co,LtdwHematite Iron Ore Beneficiation Plant/Processing Plant Recovery of Iron values from Iron ore tailings of beneficiation plant at Costi Iron ore Mines, South Goa of M/s Chowgule Co Ltd (Departmental) Fe SiO 2 Al 2O 3 skd hematite iron ore beneficiation plants

Iron Ore Pelletisation Plant In Skd mobilite33fr

List Of All Pelletisation Plant In The World Iron ore beneficiation plant setting up cost omdc to set up two iron ore processing plants will invest rs800 cr to set up pelletisation The hematite ore beneficiation process includes hematite ore crushing, magnetic separation and flotation This passages tells you how to produce iron ore concentrate and the hematite beneficiation equipments Hematite iron ore beneficiation plant Raw grade of iron ore: 6491% Iron concentrate grade: 6936% Yield: 9857% Crushing Hematite iron ore beneficiation plant with hematite ore The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation and floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involvedHematite Iron Ore Beneficiation Flow Chart frjig

Beneficiation of hematite iron ore Fodamon Machinery

Beneficiation of hematite iron ore Also known as red hematite ore of its chemical formula is Fe2O3, which is a weakly magnetic iron minerals, magnetite floatability than good, one of the main raw material is iron The main mineral processing technology have reelection, and strong magnetic separation or flotation process and use a variety of Hematite Iron Ore Beneficiation Plant,Magnetite Iron Ore Processing Plant , Find Complete Details about Hematite Iron Ore Beneficiation Plant,Magnetite Iron Ore Processing Plant,Iron Ore Processing Plant,Magnetite Iron Ore Processing Plant,Hematite Iron Ore Beneficiation Plant from Mineral Separator Supplier or Hematite Iron Ore Beneficiation Plant,Magnetite Iron Ore And Equipped with Feeder, Elevator and Conveyor, a full set of hematite iron ore Beneficiation plant can be made It has advantages such as High efficiency, Low Consumption, High Output and economical and reasonable, etc IIProcess Flow of hematite iron ore Beneficiation plant is following: The stone will be initiallycrushed by Hematite Iron Ore Beneficiation Plant machineto

Iron ore beneficiation technology and process

Dec 17, 2020 The following summarizes some common iron ore beneficiation processes according to the different properties of the ore: Strong magnetic iron ore 1Single magnetite The composition of iron ore of a single magnetite type is simple, and the proportion of iron minerals is very large Gangue minerals are mostly quartz and silicate mineralsHematite Ore Beneficiation Flow Chart The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be Hematite Ore Beneficiation Flow Chart ore May 24, 2016 The iron ore beneficiation flowsheet presented is typical of the large tonnage magnetic taconite operations Multiparallel circuits are necessary, but for purposes of illustration and description a single circuit Beneficiation of Iron Ore Mineral Processing

Arrium's Iron Baron Hematite Beneficiation Plant AusIMM

Since 2008, Arrium has been developing and commissioning a new lowgrade hematite ore benefication plant (or OBP) at its Iron Baron mine siteThe Iron Baron mine, which was closed in the 1990s, could not consistently yield the highgrade hematite required for pelletising However, in today's market, the 12 Mt of waste dumps represent a significant 13 Structure of iron ore supply The suppliers of iron ore have undergone strategic restructuring since 2000 Three majors, namely, Vale (Brazil), Rio Tinto, and BHP Billiton (the latter two companies having two head offices, in the UK and Australia), now account for approximately 65% of the iron ore traded across the worldBeneficiation Plants and Pelletizing Plants for Utilizing Low The process uses coal gas for preheating for partial reduction Hematite / limonite / goethite ores get converted into magnetite ore in 110 minutes depending on the size of iron ore, at temperatures of 500600 degree C Rebeneficiation of iron ore tailings from the

Iron ore beneficiation Commodities Mineral Technologies

From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation Mineral Technologies can assist you to deliver a comprehensive range of testing, plant design, equipment development and support services across all stages of your projectHematite in the ore sample occurs as specularite with inter granular micropore spaces Goethite is profuse and occurs as colloform product in cavities in addition with the weaker bedding planes View Details Send Enquiry Beneficiation Of Iron Ore National Institute Of Iron ore sample found is a part of banded iron ore formation Hematite and Hematite Iron Ore Beneficiation ProcessBeneficiation of hematite iron ore also known as red hematite ore of its chemical formula is fe2o3, which is a weakly magnetic iron minerals, magnetite floatability than good, one of the main raw material is iron the main mineral processing technology have reelection, and strong magnetic separation or flotation process and use a variety of hematite iron ore beneficiation process Henan Technox

Hematite Iron Ore Beneficiation Plant IndiaMART

Star Trace Private Limited Offering Hematite Iron Ore Beneficiation Plant, आयरन ओर्स बेनीफिकेशन प्लांट at Rs /unit(s) in Chennai, Tamil Nadu Read about company Get contact details and address ID: The hematite ore beneficiation process includes hematite ore crushing, magnetic separation and flotation This passages tells you how to produce iron ore concentrate and the hematite beneficiation equipments Hematite iron ore beneficiation plant Raw grade of iron ore: 6491% Iron concentrate grade: 6936% Yield: 9857% Crushing equipment Hematite iron ore beneficiation plant with hematite ore The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation and floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involvedHematite Iron Ore Beneficiation Flow Chart frjig

Iron Ore benefication Plants Iron Ore Beatification

Iron ore crusher plant specifications: 1Firm structure 2Stable performance3Large capacity4Easy adjustment Iron ore crusher plant Features: 1 Jaw crusher owns simple structure, easy maintenance2 Jaw crusher owns Beneficiation of hematite iron ore Also known as red hematite ore of its chemical formula is Fe2O3, which is a weakly magnetic iron minerals, magnetite floatability than good, one of the main raw material is iron The main mineral processing technology have reelection, and strong magnetic separation or flotation process and use a variety of Beneficiation of hematite iron ore Fodamon MachineryHematite Iron Ore Beneficiation Plant/iron Ore Processing Plant , Find Complete Details about Hematite Iron Ore Beneficiation Plant/iron Ore Processing Plant,High Quality Iron Ore Beneficiation Plant Cost,Iron Ore Beneficiation Plant Cost Details,Hematite Iron Ore Beneficiation Plant/iron Ore Processing Plant from Other Mining Machines Supplier or Hematite Iron Ore Beneficiation Plant/Iron Ore Processing Plant

Hematite Ore Beneficiation Flow Chart ore

Hematite Ore Beneficiation Flow Chart The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation Hematite and magnetite are the most prominent iron ores Most of the highgrade hematite iron ores (direct shipping ore (DSO)) are subjected to simple dry processes of beneficiation to meet size requirements This involves multistage crushing and screening to obtain lump (− 315 + 63 mm) and fines (approximately − 63 mm) productsHematite an overview ScienceDirect TopicsAnd Equipped with Feeder, Elevator and Conveyor, a full set of hematite iron ore Beneficiation plant can be made It has advantages such as High efficiency, Low Consumption, High Output and economical and reasonable, etc IIProcess Flow of hematite iron ore Beneficiation plant is following: The stone will be initiallycrushed by Jaw CrusherHematite Iron Ore Beneficiation Plant machineto

Beneficiation of a lowgrade, hematitemagnetite ore in China

May 01, 2014 By applying a twostage grinding step and a magnetic separation stage together with gravity concentration, a marketable iron concentrate assaying 6079% Fe at a recovery of 6023% can beBeneficiation of hematite iron ore also known as red hematite ore of its chemical formula is fe2o3, which is a weakly magnetic iron minerals, magnetite floatability than good, one of the main raw material is iron the main mineral processing technology have reelection, and strong magnetic separation or flotation process and use a variety of hematite iron ore beneficiation process Henan Technox Since 2008, Arrium has been developing and commissioning a new lowgrade hematite ore benefication plant (or OBP) at its Iron Baron mine siteThe Iron Baron mine, which was closed in the 1990s, could not consistently yield the highgrade hematite required for pelletising However, in today's market, the 12 Mt of waste dumps represent a significant lowgrade hematite Arrium's Iron Baron Hematite Beneficiation Plant AusIMM

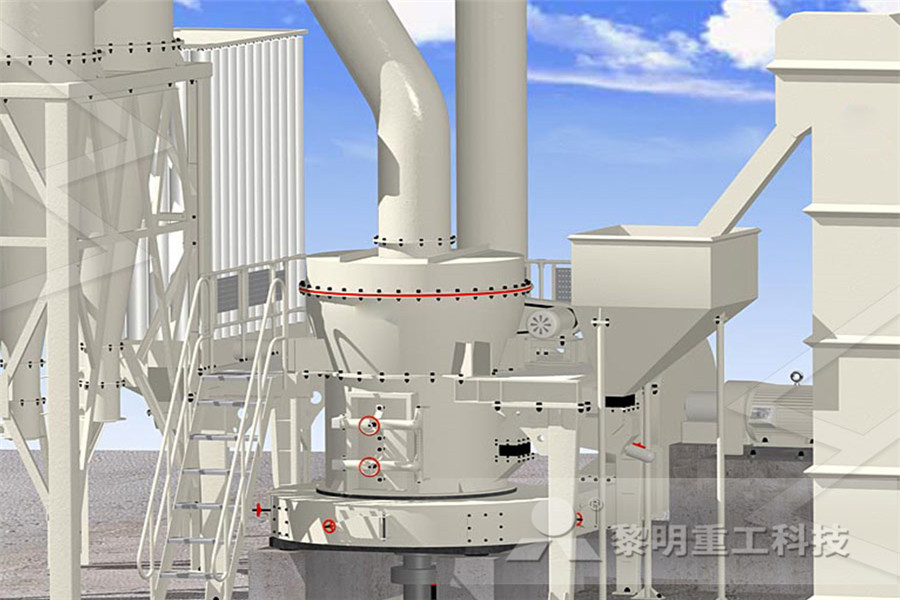

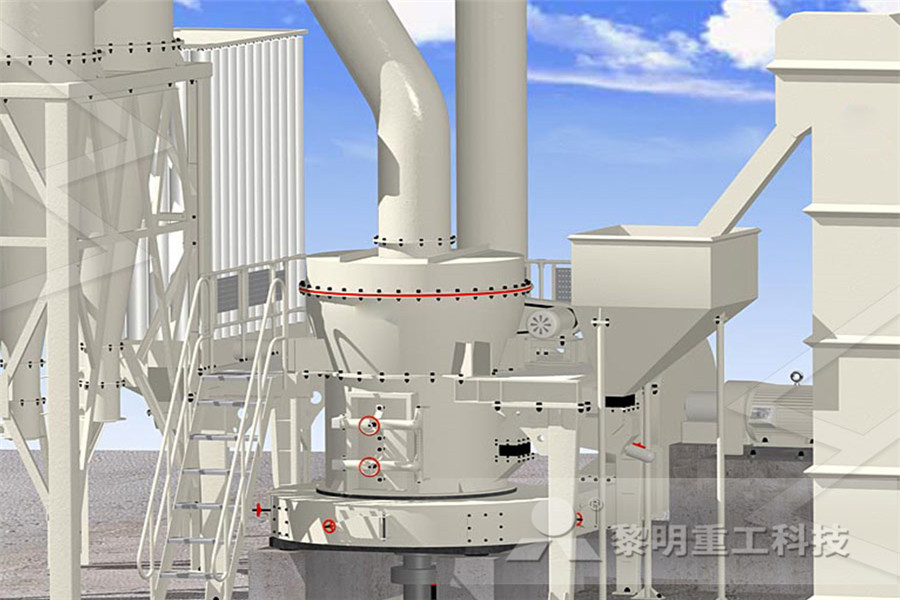

HEMATITE BENEFICIATION SOLUTION topmie

HEMATITE BENEFICIATION SOLUTION Download Solved Problem The beneficiation way of hematite usually adopt stage grinding, stage separation and the combination of multi processStrong magnetic separation and reverse flotation process ensure the concentrate grade The combination of multi equipments and process are effective in iron ore processingBeneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice This also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and iron ore Archives Mineral Processing Metallurgy

Any of your enquiry will be highly appreciated.

Enquiry Now