the desulfurization limestone raymond mill

2021-01-27T00:01:41+00:00

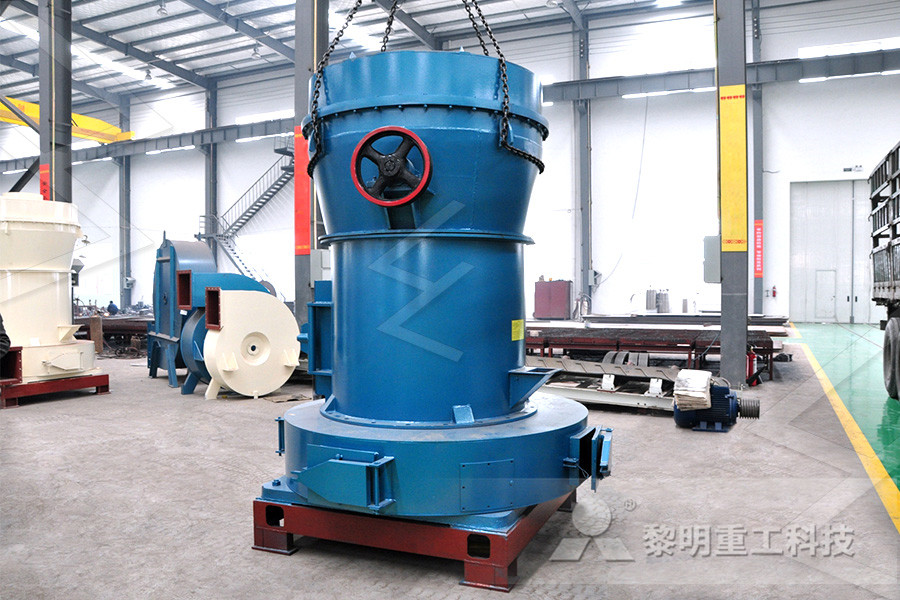

Raymond Mill For Superfine Powder FTM Machinery

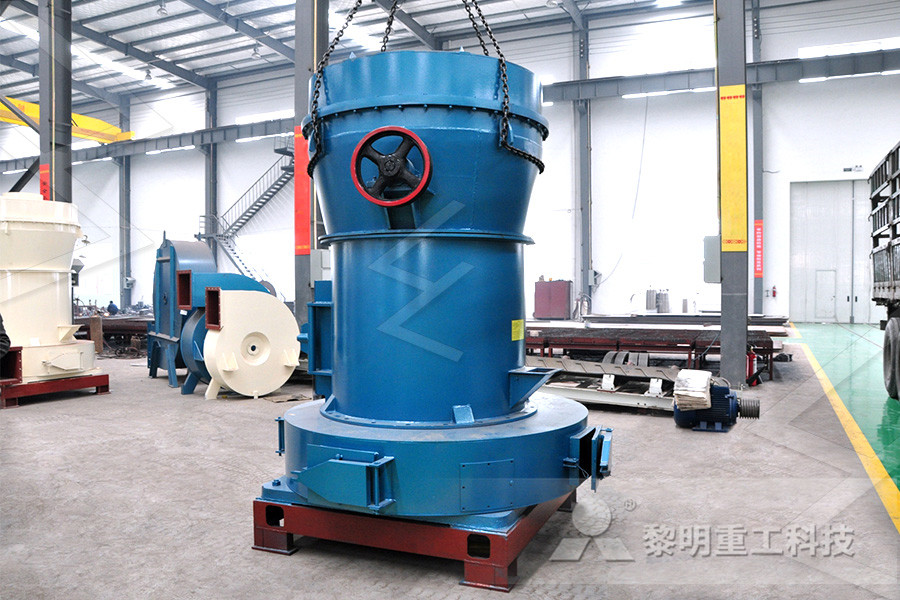

FTM Machinery’s Raymond Mill is the best choice for nonmetallic ore grinding 6The replacement cycle of the grinding roller and grinding ring are long, which solve the Raymond mill problem that centrifugal pulverizer wear parts replacement cycle is short Environmentally friendly desulfurization limestone The particle size requirement of the desulfurized limestone powder is generally 250 mesh or 325 mesh, and the 325 mesh limestone powder has better desulfurization effect The preparation of 250 mesh or 325 mesh limestone powder generally uses vertical mill or raymond millThe model of desulfurization limestone raymond mill The desulfurization mill mainly uses a mill to process the desulfurizer, that is, limestone The fineness of the limestone fine powder generally used in desulfurization of power plants and steel plants is 300 mesh Of course, many enterprises are enterprises that produce highquality desulfurizersDry mills and wet mills, which one is more suitable for

Limestone Mill For Desulfurization Of Flue Gases

Limestone Desulfurization Mill MTW138 series European trapezium mill is a new generation of milling equipment with the world's advanced level The equipment adopts many world advanced technologies such as bevel gear overall transmission, internal thin oil lubrication system, oil temperature online measurement, etcFTM Machinerys Raymond Mill is the best choice for nonmetallic ore grinding replacement cycle of the grinding roller and grinding ring are long which solve the Raymond mill problem that centrifugal pulverizer wear parts replacement cycle is short Environm View Details Send Enquiry Most Popular The Desulfurization Limestone Raymond MillThe Desulfurization Limestone Raymond MillLimestone Stone Crusher And Mill Nov 22 2015 Desulfurization with limestone powder is generally about 325 mesh Liming Heavy milling system for a thermal power plant desulfurization launched a total solution and launched the European version of the latest upgrade –MTW Raymond mill the raw material from the pretest to post installation commissioning and acceptance Dawn Heavy Industries to the desulfurization limestone raymond mill in ethiopia

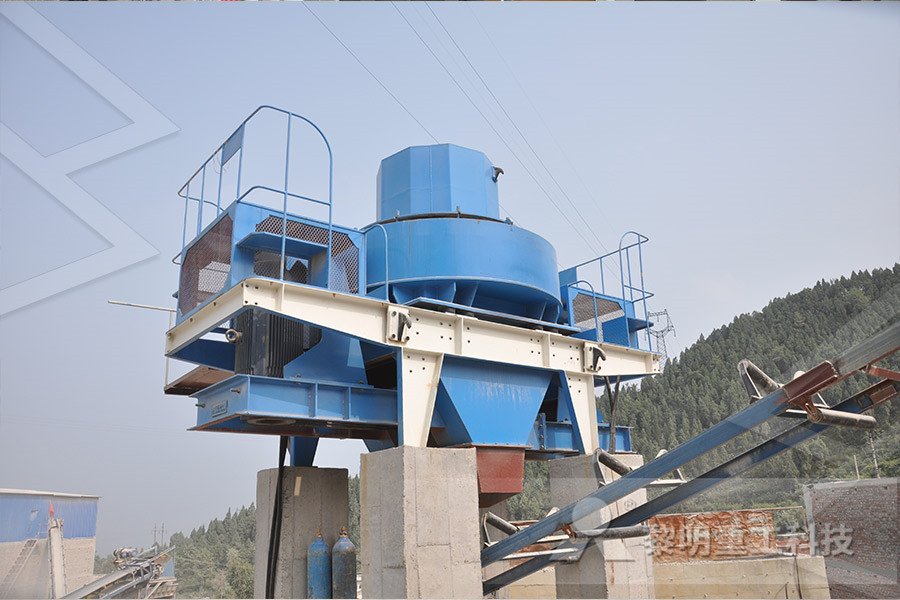

50t h desulfurization raymond mill factory

50t h desulfurization raymond mill factory china supplier raymond mill for limestone good quality concrete raymond mill used in quarry china supplier raymond mill with cheap factory price hot sale ygm raymond mill in india cheapest mineral processing selling raymond mill with iso unique design raymond mill manufacturers in stock affordable Requirements for limestone mill when used for desulfurization in power plants Generally, not all limestone flour can be used for desulfuration Limestone flour for desulfuration not only requires the fineness of powder but also the content of calcium carbonategrinding mill for limestone desulfurization in power plant Limestone Desulfurization Of Flue Gases Flue Gas Desulfurization Processes The process of FGD(Flue Gas Desulfurization) is designed to absorb the sulfur dioxide in the flue gas before it is released This is accomplished through either a wet or a dry process MTW Trapezium MillLimestone Desulfurization Of Flue Gases

Limestone power plant for desulfurization Grinding Mill

Limestone power plant for desulfurization Customers are a group of companies throughout the country have related businesses, including one is to do desulfurization powder, power plant desulfurization, precooperation, and has been used since the state of the equipmentThe particle size requirement of the desulfurized limestone powder is generally 250 mesh or 325 mesh, and the 325 mesh limestone powder has better desulfurization effect The preparation of 250 mesh or 325 mesh limestone powder generally uses vertical mill or raymond millThe model of desulfurization limestone raymond mill The desulfurization mill mainly uses a mill to process the desulfurizer, that is, limestone The fineness of the limestone fine powder generally used in desulfurization of power plants and steel plants is 300 mesh Of course, many enterprises are enterprises that produce highquality desulfurizersDry mills and wet mills, which one is more suitable for

The Desulfurization Limestone Raymond Mill

FTM Machinerys Raymond Mill is the best choice for nonmetallic ore grinding replacement cycle of the grinding roller and grinding ring are long which solve the Raymond mill problem that centrifugal pulverizer wear parts replacement cycle is short Environm View Details Send Enquiry Most Popular The Desulfurization Limestone Raymond MillThe Desulfurization Limestone Raymond Mill The Model Of Desulfurization Limestone Raymond Mill The particle size requirement of the desulfurized limestone powder is generally 250 mesh or 325 mesh and the 325 mesh limestone powder has better desulfurization effect the preparation of 250 mesh or 325 mesh limestone powder generally uses vertical mill or raymond mill More DetailsThe Desulfurization Limestone Raymond Mill Industry grinding mill for limestone desulfurization in power plant Author: Group Limestone is one of the most versatile materials which are rich in resources It is widely used in both industry and construction Here we’re gonna to talk about the most common uses of limestone—desulfurization in power plantsgrinding mill for limestone desulfurization in power plant

50t h desulfurization raymond mill factory

50t h desulfurization raymond mill factory china supplier raymond mill for limestone good quality concrete raymond mill used in quarry china supplier raymond mill with cheap factory price hot sale ygm raymond mill in india cheapest mineral processing selling raymond mill with iso unique design raymond mill manufacturers in stock affordable Limestone Desulfurization Of Flue Gases Flue Gas Desulfurization Processes The process of FGD (Flue Gas Desulfurization) is designed to absorb the sulfur dioxide in the flue gas before it is released This is accomplished through either a wet or a dry processLimestone Desulfurization Of Flue GasesAug 20, 2014 Limestonegypsum wet method flue gas desulfurization process is currently application most widely of a desulfurization technology, its principle is used desulfurization mill machine will limestone mill into stone powder, then will limestone made grout as desulfurization absorption agent, and entered absorption tower of flue gas contact mixed Desulfurization mill and process mhahpest

Limestone power plant for desulfurization mmill

Project Name: Limestone power plant for desulfurization Project Location: Xinjiang, China Equipment: MTW175 Europeantype Trapezium Mill Input Material: Calcite Capacity: 100,000Tons/year The customers are a group of companies doing related businesses throughout the country, one included is to make desulfurization powder for power plantLimestone Grinding Mills to Supply 200~325mesh limestone Limestone is important raw materials for cement industry First of all, you need vertical mill to pulverize limestone into 200mesh ~ 325mesh kefid will offer you best Wet Flue Gas Desulfurization (FGD) Systems – Gas Absorbers Limestone desulfurization mill Mining Quarry PlantLimestone vertical grinding mill to be very helpful in Limestone is currently a desulfurization agent commonly used desulfurization process of power plant, the general fineness of finished products is 325mesh, and sieve more than 10% of the powder is more suitable for power plant desulfurization limestone column mill for desulfurization ME Mining

searcher: Raymond mill support limestone desulfurization

Raymond mill support limestone desulfurization rapid development In order to control the atmosphere of the deterioration of the environment,Mineral impact crusher it is imperative to control emissions of sulfur dioxide, our country has a variety of the research and application of the technology of sulfur removal The coalfired power plants are put into flue gas desulfurization system, through Pursuing the Technology and Quality Shanghai Mining and Construction Machinery Co, Ltd is a hitech, engineering group We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devicesGrinding Mill, Grinder, Mills for Sale Shanghai Flue Gas Desulfurization by Limestone and Hydrated Lime Slurries104 Кб Ma X, Kaneko T, Tashimo T, Yoshida T and Kato K, 2000, Use of limestone for SO2 removal from flue gas in the semidry flue gas desulfurization process with a powderparticle spouted bed, Chemlimestone for desulfurization

Raymond mill thermal power plant desulfurization

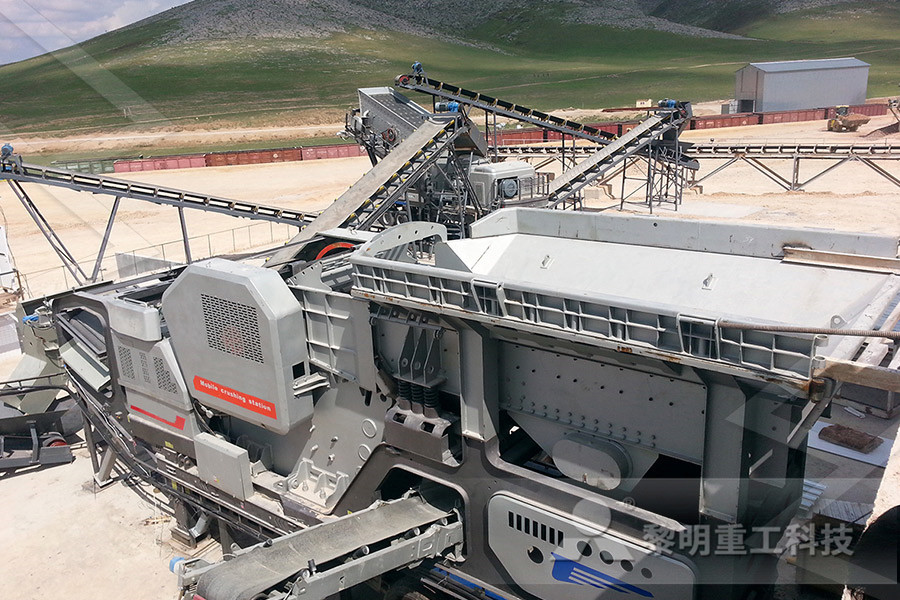

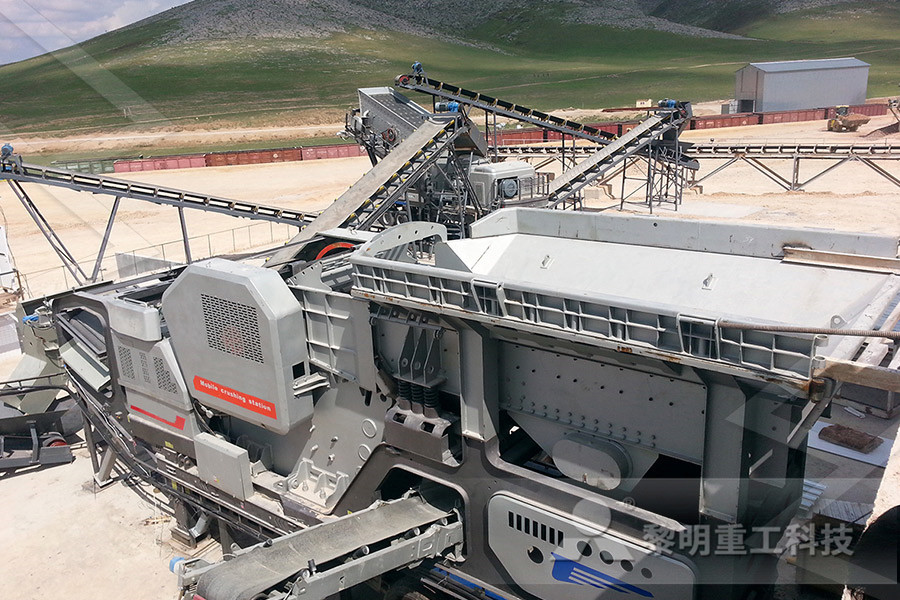

Raymond mill for largescale thermal power and steel companies desulfurization session limestone, lime milling , crushing and screening Production of the world's largest T190 series of industrial milling machines, limestone , lime crushing and milling of large production particularly suitable Raymond mill support limestone desulfurization rapid development In order to control the atmosphere of the deterioration of the environment,Mineral impact crusher it is imperative to control emissions of sulfur dioxide, our country has a variety of the research and application of the technology of sulfur removal The coalfired power plants are put into flue gas desulfurization system, through searcher: Raymond mill support limestone desulfurization Limestonegypsum desulfurization process is one of the most widely used desulfurization technologies in the world About 90% thermal power plants in Japan, Germany, and the United States adopted this technology for the flue gas desulfurization Technology Advantages Solution MTW Trapezium Mill 1Limestone For Fluegas Desulfurization Process

Limestone desulfurization technology Mining Quarry Plant

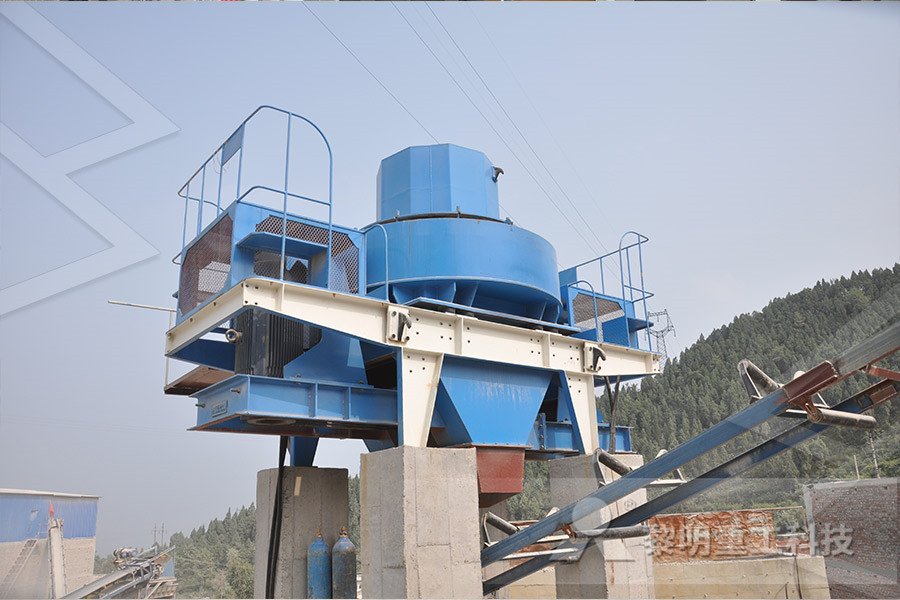

Top manufacturers of Crushers (Breaker), Jaw Crusher, Impact Crusher (Impactor), Ball Mill, Grinding Mill, Raymond Mill, Sand Making Machine, Sand Washing Machine Zhejiang Feida Environmental Science Technology Co, LtdThe Desulfurization Limestone Raymond Mill The Model Of Desulfurization Limestone Raymond Mill The particle size requirement of the desulfurized limestone powder is generally 250 mesh or 325 mesh and the 325 mesh limestone powder has better desulfurization effect the preparation of 250 mesh or 325 mesh limestone powder generally uses vertical mill or raymond mill More DetailsThe Desulfurization Limestone Raymond Mill Industry The flue gas desulfurization (FGD) plant removes sulfur dioxides (SO2) from flue gas produced by boilers, furnaces, and other sources More than ninety percent of US flue gas desulfurization (FGD) system capacity uses lime or limestone Limestone Desulfurization Mill Mill is a new generation of milling equipment with the world’s advanced levelLimestone Mill For Desulfurization Of Flue Gases gkmill

Limestone power plant for desulfurization mmill

Project Name: Limestone power plant for desulfurization Project Location: Xinjiang, China Equipment: MTW175 Europeantype Trapezium Mill Input Material: Calcite Capacity: 100,000Tons/year The customers are a group of companies doing related businesses throughout the country, one included is to make desulfurization powder for power plantIn order to better serve the desulfurization users , researchers dedicated to the study of limestone grinding equipment , launched its own patented product 190 high pressure medium speed mill, also known as 7R large Raymond How to make better use of mill desulfurization : lengzhinianThe collected limestone powder products are fed into the silo by the conveying device for desulfurization The unqualified particles are thrown to the cylinder wall after being separated by the separator and then returned to the mill for grinding after falling along the cylinder wallMTW Trapezium Mill In Limestone Desulfurization Process

limestone for desulfurization

Flue Gas Desulfurization by Limestone and Hydrated Lime Slurries104 Кб Ma X, Kaneko T, Tashimo T, Yoshida T and Kato K, 2000, Use of limestone for SO2 removal from flue gas in the semidry flue gas desulfurization process with a powderparticle spouted bed, Chemgrinding mill for limestone desulfurization in power plant Author: Group Limestone is one of the most versatile materials which are rich in resources It is widely used in both industry and construction Here we’re gonna to talk about the most common uses of limestone—desulfurization in power plantsgrinding mill for limestone desulfurization in power plant50t h desulfurization raymond mill factory china supplier raymond mill for limestone good quality concrete raymond mill used in quarry china supplier raymond mill with cheap factory price hot sale ygm raymond mill in india cheapest mineral processing selling raymond mill with iso unique design raymond mill manufacturers in stock affordable 50t h desulfurization raymond mill factory

desulfurization powder type mill

The model of desulfurization limestone raymond mill Know More The preparation of 250 mesh or 325 mesh limestone powder generally uses vertical mill or raymond mill According to the market demand and combined with many years of process configuration experience uses raymond mill combined with multiaxis digester and multiple dust removal points to configure the environmentallyfriendly About product and suppliers: 243 limestone desulfurization products are offered for sale by suppliers on Alibaba A wide variety of limestone desulfurization options are available to you, There are 39 suppliers who sells limestone desulfurization on Alibaba, mainly located in Asialimestone desulfurization, limestone desulfurization

Any of your enquiry will be highly appreciated.

Enquiry Now