Hpgr Mining Mill Iron Ore

2023-06-20T22:06:34+00:00

HPGR and Iron Ore Processing SlideShare

18 j ENVIRONMENTAL PROCESSING DESIGN VERIFICATION PRODUCT INNOVATION PROJECT MANAGEMENT OPERATIONS TRAINING SKILLS HIRE Khumani Mine • High grade hematite deposit in South Africa • As an energysaving alternative to the SAG mill, HPGR is particularly suited for the pregrinding of hard, highly siliceous gold ores This will help to HPGR High Pressure Grinding Rolls Mineral The present work studied the performance of a pilotscale HPGR pressing an iron ore concentrate under a variety of conditions that are consistent with pregrinding As already Pressing iron ore concentrate in a pilotscale HPGR Part 1

HPGR CEEC (Coalition for Eco Efficient Comminution)

The High Pressure Grinding Rolls (HPGR) is a relatively new comminution technology that has been shown to be more energy efficient compared to semi autogeneous (SAG) mills An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of Grinding iron ore concentrate by using HPGR and ball Today, the ironore industry uses HPGRs to prepare pellet feed for finishing grinding after wetball milling and filtering The wetball mill product is more readily filtered without the Developments in HPGR technology Mining Magazine

High pressure grinding rolls (HPGR) Outotec

High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores They compress the feed material between two rotating rollers, one of which is in a fixed position and Weir Group wins major HPGR and screens order from iron ore major Ferrexpo Posted by Paul Moore on 29th April 2021 The Weir Group has been awarded a £36 million order to provide industryleading energy saving Weir Group wins major HPGR and screens order Iron ore concentrate regr inding in ball mill and HPGR The iron ore concentrate was re ground and Blaine value increased from 1031 to about 1400, 16 00, 1800 cm 2 /gr by using The effects of iron ore concentrate grinding methods

Enduron® HPGR – the principal choice in iron ore

Weir Minerals’ high pressure grinding roll (HPGR) technology is fast becoming the staple for an increasingly diverse range of hard rock mining applications Although iron ore accounts for the majority of the Enduron® installed base, HPGR technology is also increasingly being adopted for copper and gold applicationsFeatures in ore mining rod mill, ball mill, for an HPGR system is with lower energy consumption for 20 to 50% Significantly improve the followup process like flotation, leaching, etc The segment service life for hardness ore normally is 6,000 to 10,000 hours while for mediumlow hardness iron ore is 10,000 to 18,000 hours The (HPGR) high pressure grinding rolls/rollers for cement, The Coalition for Energy Efficient Comminution (CEEC) has been established and is supported by a broad range of mining sector companies keen to accelerate awareness, knowledge transfer and, by implication, improve energy and cost outcomes in the substantive area of comminution HPGR CEEC (Coalition for Eco Efficient Comminution) Toggle navigationHPGR CEEC (Coalition for Eco Efficient Comminution)

application of hpgr mills in iron ore processing

the applicability for hard rock mining operations Whilst the test results for the HPGR type of VRM) than a ball mill circuit for a similar degree of comminution Key words: CopperGold in Indonesia, CVRD Iron Ore in Brazil, Kudremukh Iron Get Price; considerations for multistage hpgr grinding in iron ore processingLorem ipsum dolor Address: No169, Science (Kexue) Avenue, Tel: 0086371 : [ protected]appliion of hpgr mills in iron ore processing An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particles The effects of grinding mechanisms on generating pellet feed were assessed and pellets and DRIs were producedGrinding iron ore concentrate by using HPGR and ball

The effects of iron ore concentrate grinding methods

PDF On Oct 18, 2020, Seyed Hamzeh Amiri and others published The effects of iron ore concentrate grinding methods (HPGR and Ball mill) on green pellet properties a pilot plant case study Find Ore Blend Grinding at HPGR and Ball Mill The ore blend was ground in a pilotscale HPGR (1 m diameter × 032 m width) at a maximum feed rate of 50 t/h The ground product was recirculated to the HPGR feeding hopper five or seven times, wherein every recirculation steps a sample was gathered for moisture and size distribution measurementDevelopment of a Novel Grinding Process to Iron Ore Thyssenkrupp and Enter Engineering have signed an Agreement of Intent worth €50 million (US$585 million) on building an integrated mining metallurgical complex at Tebinbulak The HPGR plant will be used to help process up to 60 Thyssenkrupp wins €50M Uzbek HPGR project Mining

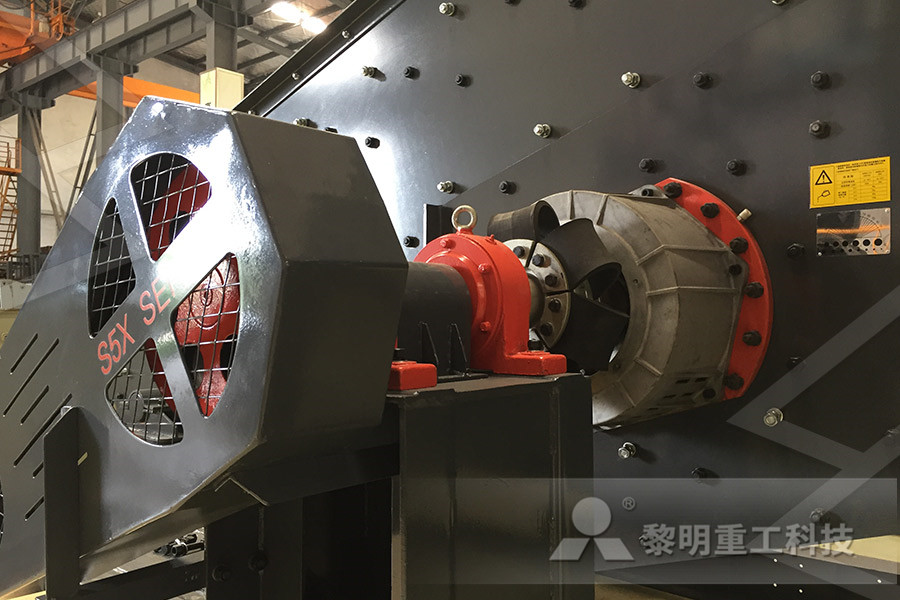

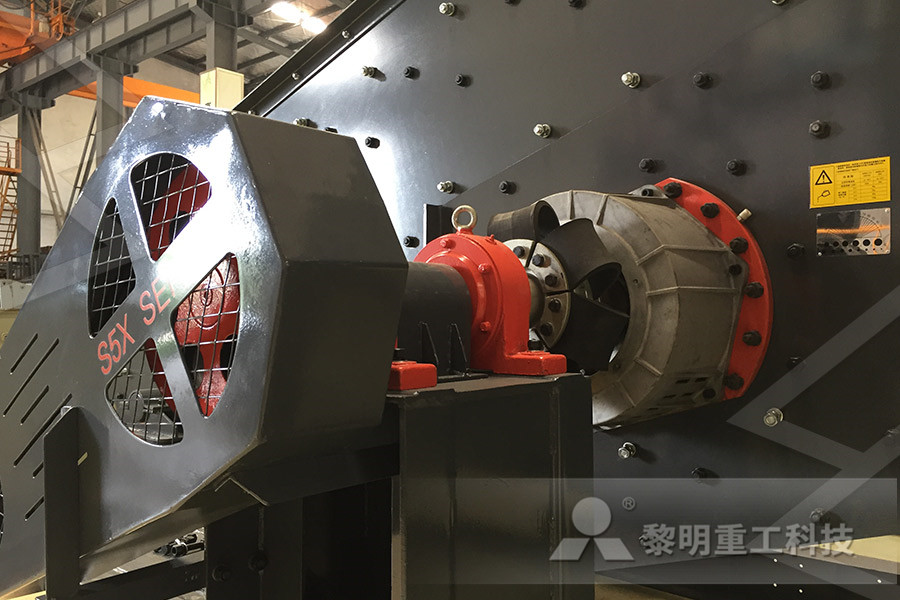

(HPGR) high pressure grinding rolls/rollers for cement,

Features in ore mining rod mill, ball mill, for an HPGR system is with lower energy consumption for 20 to 50% Significantly improve the followup process like flotation, leaching, etc The segment service life for hardness ore normally is 6,000 to 10,000 hours while for mediumlow hardness iron ore is 10,000 to 18,000 hours The 10 los colorados operation iron ore the crushing and preconcentration plant is located near the mine after rail transport to the pellet plant, the magnetic preconcentrate is ground in ball mills to pellet feed fineness and further concentrated by wet magnetic separation figure 1 shows a schematic flow sheet of the los colorados hpgr circuithpgr screens and hpgr crushers in iron ore plants croatiaThe process of highpressure grinding and the properties of its product are very different from those of conventional crushers or grinding mills, and the industry has learned to use this to its advantage in new applications Today, the ironore industry uses HPGRs to prepare pellet feed for finishing grinding after wetball milling and filteringhpgr crushers in iron ore mines bhaktibe

HPGR CEEC (Coalition for Eco Efficient Comminution)

HPGR HPGR Coarse vertical stirred mill applications Ballantyne, Foggiatto, Staples, Lane Presented at the AusIMM Mill Operators Conference June 2021 ABSTRACT This trend is being driven by reductions in footprint and operating cost 20Jul2021 Ore hardness effect on design of comminution circuits which use competing technologies: Lorem ipsum dolor Address: No169, Science (Kexue) Avenue, Tel: 0086371 : [ protected]appliion of hpgr mills in iron ore processingthe applicability for hard rock mining operations Whilst the test results for the HPGR type of VRM) than a ball mill circuit for a similar degree of comminution Key words: CopperGold in Indonesia, CVRD Iron Ore in Brazil, Kudremukh Iron Get Price; considerations for multistage hpgr grinding in iron ore processingapplication of hpgr mills in iron ore processing

Grinding iron ore concentrate by using HPGR and ball

An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particles The effects of grinding mechanisms on generating pellet feed were assessed and pellets and DRIs were produced Thyssenkrupp and Enter Engineering have signed an Agreement of Intent worth €50 million (US$585 million) on building an integrated mining metallurgical complex at Tebinbulak The HPGR plant will be used to help process up to 60 million tons of iron ore per year, said the companiesThyssenkrupp wins €50M Uzbek HPGR project Mining

Any of your enquiry will be highly appreciated.

Enquiry Now