explain crushing and grinding processing

2019-03-19T10:03:32+00:00

Crushing Vs Grinding Minerallurgy

The size reduction operation in the plant takes place as a sequence of crushing and grinding processes In crushing, particles are reduced in size to such a level that grinding can be conducted, while grinding allows to achieve the desired liberation sizeThe crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumptionCrushing and Grinding Process JXSC MachineJul 01, 2015 Comminution in the mineral processing plant takes place in a sequence of crushing and grinding (and/or milling) Crushing reduces particle size of runofmine ore to such a level that grinding COMMINUTION: Liberation, Crushing, Grinding

Mineral processing metallurgy Britannica

Yet another development, combining the processes of crushing and grinding, is the roll crusher This consists essentially of two cylinders that are mounted on horizontal shafts and driven in opposite directions The cylinders are pressed together under high pressure, so that comminution takes place in the material bed between themSize reduction by crushing has a size limitation for the final products If further reduction is required, below 5 20mm, grinding processes should be used Grinding is a powdering or pulverizing process using the rock mechanical forces of impaction and attrition The AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator Home » Crushing Grinding CinChemPro has the capacity for processing a wide variety of friable materials in hammer mills, reducing materials from large chunks to products of less than 100 microns Our crushing and grinding operation includes blenders, dust Crushing Grinding CinChemPro, LLC

Mineral processing Wikipedia

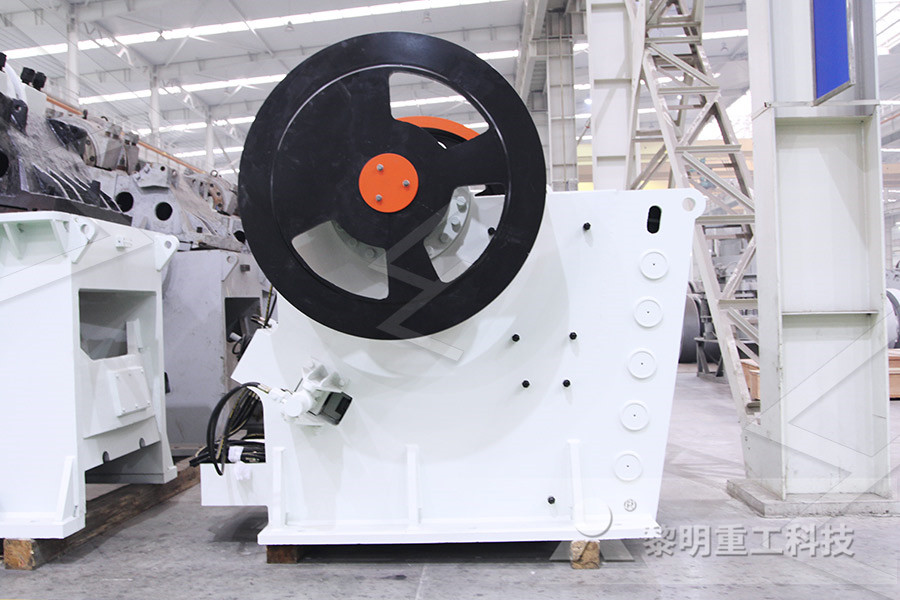

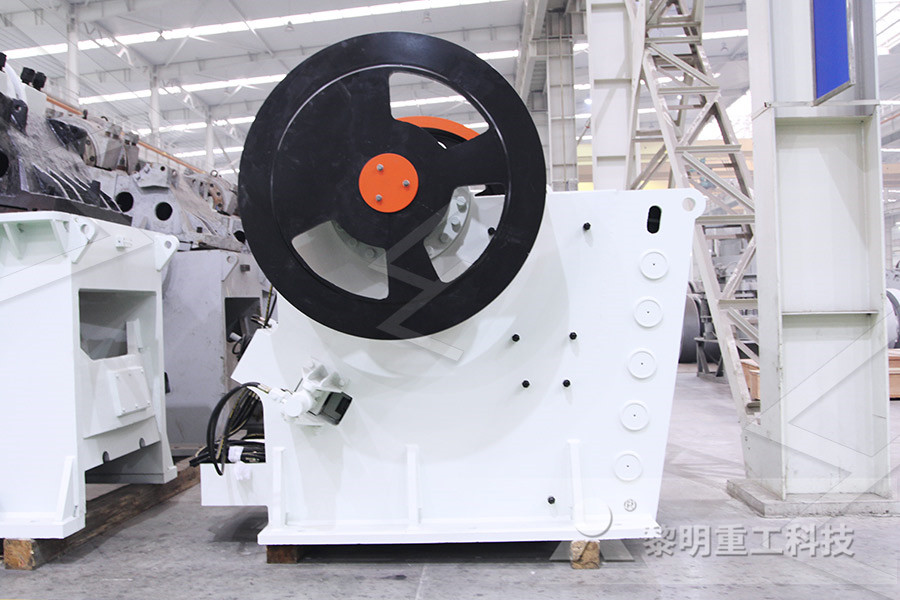

The primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more In cement: Crushing and grinding containing a charge of steel grinding balls This grinding is done wet or dry, depending on the process in use, but for dry grinding the raw materials first may need to be dried in cylindrical, rotary dryersGrinding materials processing BritannicaThe Grinding Process Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling Grinding employs an abrasive product, usually a rotating wheel Basics of Grinding Manufacturing

grinding iron ore flow process in colombia

grinding iron ore flow process in colombia and detailed iron ore mining process flow chart please contact our customer service they will be detailed to you to explain the process and provide detailed As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc When making comparisons of the efficiencies of different grinding and crushing machines it is desirable to be able to estimate the work actually done in crushing the ore from a given size of feed to a given size of product, the screen analysis of both feed and product being determined Messrs Klug and Taylor, in a paper on this subject, published in the monthly journal of the Chamber of Mines Difference between Crushing and GrindingCrushing and Grinding Crushing and Grinding Our crushers are designed and built with advanced technology and stringent quality control at every stage of the manufacturing process, to meet the rigorous demands of aggregate operations A leading supplier to the aggregate industry Crushing and Grinding The Weir Group

Basics of Grinding Manufacturing

The Grinding Process Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling Grinding employs an abrasive product, usually a rotating wheel CinChemPro has the capacity for processing a wide variety of friable materials in hammer mills, reducing materials from large chunks to products of less than 100 microns Our crushing and grinding operation includes blenders, dust collectors, and packaging equipmentCrushing Grinding CinChemPro, LLCIn cement: Crushing and grinding containing a charge of steel grinding balls This grinding is done wet or dry, depending on the process in use, but for dry grinding the raw materials first may need to be dried in cylindrical, rotary dryersGrinding materials processing Britannica

process of crushing gold theselahprojectcoza

crushing and grinding processing gold mine crushing and grinding processing gold mine (a unit process of mining) with crushing and grinding (processing steps) has been the key factor in the discovery of major copper and gold deposits Read More Can you tell me the gold ore Crushing process the machine or the 2 AnswersPosted in topics A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand (eg, via a hand crank), working animal (eg, horse mill), wind or water ()Mill (grinding) WikipediaCrushing is the largest process operation in minerals processing The goal is to pr oduce rock or (more seldom) mineral fractions to be u sed as rock fill or ballast material for concrete and a sphalt(PDF) SIZE REDUCTION BY CRUSHING METHODS

Crushing in Mineral Processing

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Objectives At the end of this lesson students should be able to: Explain the grinding process Distinguish between crushing and grinding Compare and contrast different type of equipment and their components used for grinding Identify key variables for process control Design features of grinding equipment (SAG, BALL and ROD MILLS) []AMIT F135 – Mining Mill Operator TrainingComminution (ie, the breaking of rock to facilitate the separation of ore minerals from waste) combines blasting (a unit process of mining) with crushing and grinding (processing steps) Insitu mining, which is treated under a separate heading in this chapter, is a special case that combines aspects of mining and processing but does not 3 Technologies in Exploration, Mining, and Processing

is grinding a mixture of processes explain

Explain special features of grinding processGrinding abrasive cutting wikipedia grinding is a mixture of processMachining material removal processesWhile typically used to improve the surface finish of a part abrasive machining can still be used to shape a workpiece and form featuresThe most common abrasive machiningThe two m ain purposes for a grinding process are: The processing like crushing will disintegrate and unlock the values from the waste, so that the methods of separation will be able to part (PDF) SIZE REDUCTION BY GRINDING METHODSRoller mill With a roller mill, a product is compressed and reduced between two counterrotating rotating rollers A major advantage of this process is that the proportion of fine particles (powders or dust) remains minimal compared to other grinding principles and that a nice homogeneous grainsize distribution is achievableMilling Grinding Process Technology Contact us

How it Works: Crushers, Grinding Mills and Pulverizers

Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can be classified into to two basic types, crushers and grindersAs is known to all, the dressing operation consists of three stages: predressing, dressing and postdressing The preparatory work before mineral dressing generally includes crushing and screening, grinding classification, hand sorting and washing, among which grinding classification is the followup technology of crushing and screening and also an important process in the predressing stageDo You Understand The Grinding And Classifying Process In CinChemPro has the capacity for processing a wide variety of friable materials in hammer mills, reducing materials from large chunks to products of less than 100 microns Our crushing and grinding operation includes blenders, dust collectors, and packaging equipmentCrushing Grinding CinChemPro, LLC

crushing process grinding in france

crushing process grinding in france Crushing and Grinding Crushing is the first mechanical stage in the process of comminution in which the main objective is the liberation of the valuable minerals from the gangue In the nature minerals are usually intergrowth with other mineral species In order to separate them they must be unlocked through comminution crushing and grindingCrushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rockscrushing and grinding mineral processingHow to choose limestone crushing and milling process Today we will explain to everyone about the limestone crushing or milling process, and how to choose the right processing technology to obtain allround utilization of materials During the same rotation process between the blade and the grinding roller, the material is shoveled and How to choose limestone crushing and milling process

Grinding Process Mineral Processing Metallurgy

In the previous chapter, the various “laws” of comminution which have been propounded have been studied in relation to the physical process of size reduction and to the available results of experiments into the fracture of homogeneous and heterogeneous materials by impact and by slow compression In this study it is seen that no satisfactory “law” of comminution has yet been deduced crushing and grinding manufacturing process diagram GIF is used extensively in the paper manufacturing industry A process flow diagram for kaolin mining and dry processing is presented in Figure 11251 and Figure 11252 illustrates the wet processing of kaolincrushing and grinding manufacturing process diagram ME Crushing and grinding process samac samac coal surface mining gold ore crusher and grinding machine is widely used in gold rock gold grinding get p south africa s best herb grinding machine samac crushing and grinding process samac each possible mineral recovery process has a certain size range of best rajasthan line mill in southcrushing and grinding process samac

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

Explain typical flowsheets of grinding circuits involving single or combination of equipment; Reading Lecture Size reduction by crushing has a size limitation for the final products If further reduction is required, below 5 20mm, grinding processes should be used Grinding is a powdering or pulverizing process using the rock mechanical Chapter 3 Aggregates changing their nature during the process of production such as crushing and grinding Some examples in this category are sand, crushed limestone, and gravel proportion since sand gradation has the largest effect on workabilityeffects of crushing and grinding in samplesThe grinding process, that will need to be improved and carefully revised to reduce ore transportation, crushing, grinding, classification by size, direct flotation, must be considered as well, although Sphalerite (1 %) contents were too low tosphalerite crushing grinding process

Pulverization 1: Definition and purpose THINKY USA

Oct 31, 2019 “Pulverization” (comminution, crushing, grinding) is the process of applying an external force to a (solid) material of a certain size to destroy it and reduce it into pieces that are smaller than the original size Pulverization has long been done for many materials, including ore, glass, ceramics, grains, paints, and medicines

Any of your enquiry will be highly appreciated.

Enquiry Now