RAW MILL FOR CEMENT CANANA

2021-11-26T13:11:42+00:00

Cement Plants located in Canada The Global Cement Report

Cement Plant Location Information for Canada Cement plant locations and information on Canada can be found below For full access to the database, purchase The Global Cement Report™, 13th EditionA raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the Rawmill WikipediaCCR Vertical Raw Mill Operator in Cement Company : Resume CV catering, chief engineer, computer software, resume: Location Sudan Project 12012010 to 24072010 Cement Process Engineers, Cement kiln process troubleshooter Process calculations for Raw Mill Loesche vertical roller mills for raw and cement investigation of possible Vertical Raw Mill In Barbra Cement In Sudan Crusher

Raw Mill In Cement Plant by China ZK Supplier from China

Raw mill has features such as high capacity, high efficiency, energy saving and environmental protection Raw mill usually is used for grinding various ores and other materials in cement, electric power, metallurgy, chemical industry and other industry Our products special features: 1 Product fineness is adjustable and uniform 2In the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between Prehomogenization and raw milling, and has not been discussed separately by most of the authors However, in my opinion it remains and must remain as of pivotal importance, so far as the quality assurance is consideredRaw Mill Feeding Cement Plant OptimizationRaw Mill In Cement Plant Gearbox Papua New Guinea Raw mill in cement plant gearbox papua new guineaCement cemexCement is a fine powder obtained from the calcination at 1 450 176 c of a mix of limestone clay and iron ore the product of the calcination process is clinkerthe main ingredient of cementthat is finely ground with gypsum and other chemical additives to produce cementRaw Mill For Cement Plant rubberskirting

Raw Mill for Cement Plant Fote Machinery(FTM)

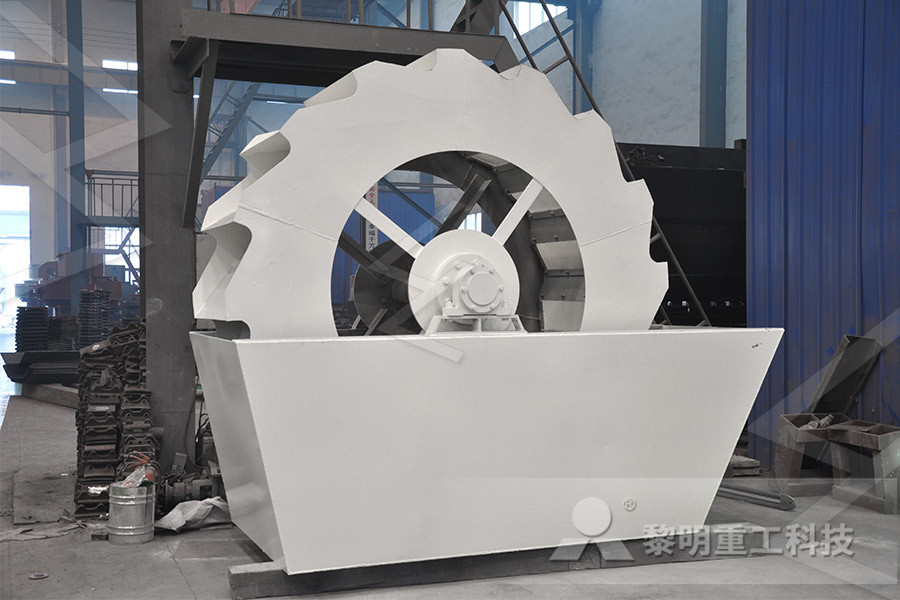

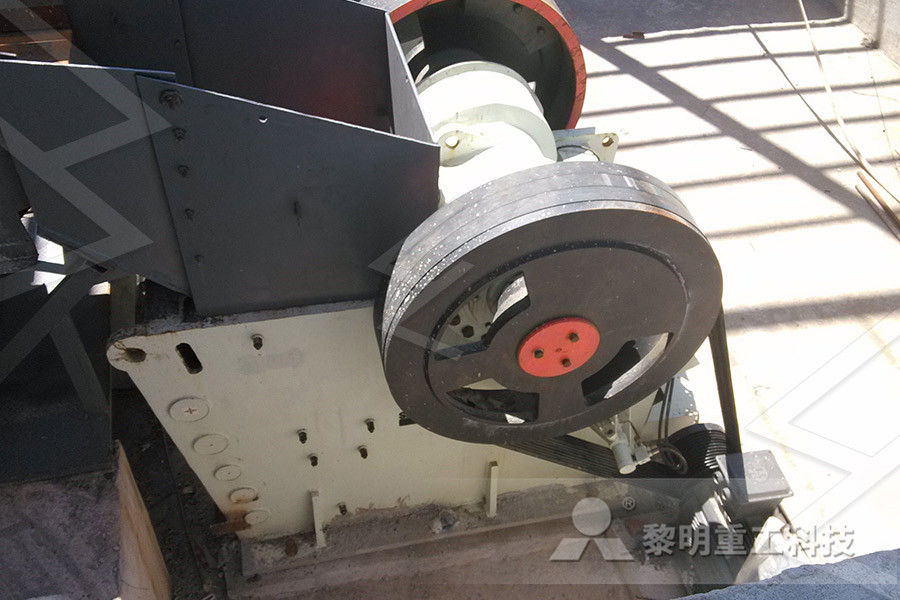

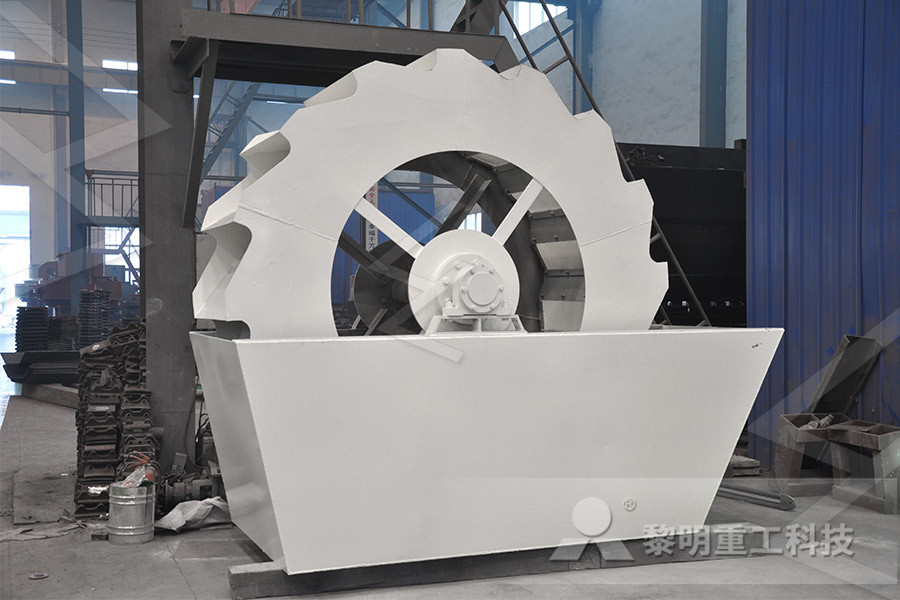

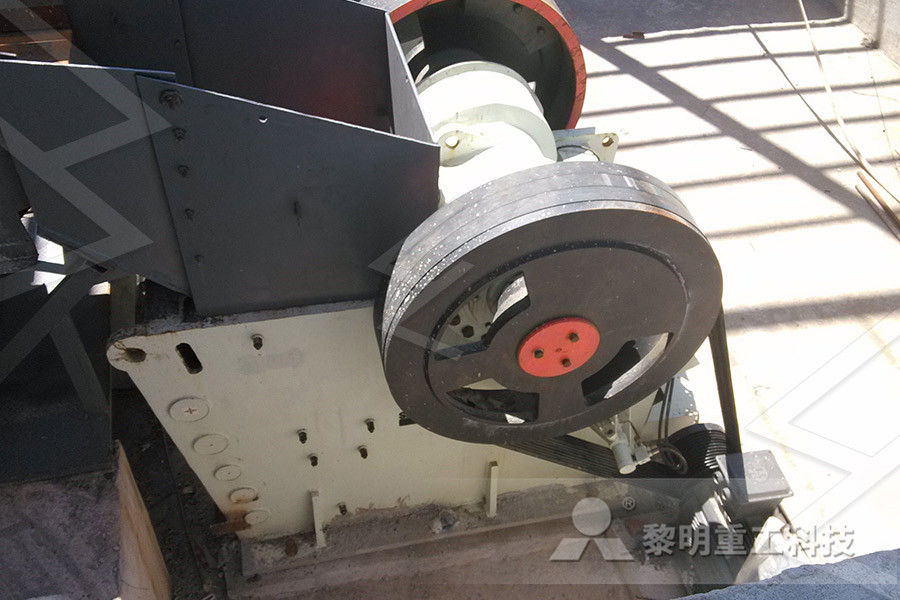

What is Raw Mill? Raw mill is also called raw material mill, which is the essential equipment in the production process of cement It has large application such as raw mill in cement plant, building materials, metallurgy, electric power and chemical industry, which is mainly used for the grinding as well as drying of cement raw materials and other materialscement raw mill ball mill grinding indonesia Cement Mill Grinding MediaPage 1 of 1 Nov 01 2017 re Cement Mill Grinding Media H there These are just the basics if you want to accurately do it you have to fill it up to 80 BC and then do a longitudinal sieving and then correct the BC based on the resultscement raw mill ball mill grinding indonesiaRawmill WikipediaOverviewHistoryMaterials groundControl of minor elementsWet rawmillsDry rawmillsA raw mill is the equipment used to grind raw materials into qraw mill on cement kiln stockalperturmch

116 Portland Cement Manufacturing

Aug 17, 1971 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and theseCement mill (cement ball mill) is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics, etc in cement plant, cement grinding station and other cement industries Cement mill can grind ore or other materials by wet process or by dry Cement mill,Cement mill price,Raw material mill,China Raw mill is used widely for grinding (both drying and grinding) cement raw material and other materials in buinding material, metallurgical, electric and chemical industries Sorts and features: Common raw mill: It is used for small mediumsized raw materials grinding system which generally is cycle flow system with material separating system Raw Mill In Cement Plant Equipment Manufacturer Buy Raw

Cement and Raw Mill A TEC Innovative Technologies for

Cement and Raw Mill Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power consumption HURRICLON® , installed after the mill classifier, again proves to be the best technology for the mill product collection, providing top separation Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary grinding after crushing And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding Raw mill is mainly used in grinding raw materials and end products in cement plantRaw Mill,Raw Mill In Cement PlantThis is the 3rd part in a cement plant The process is mentioned in the enclosed movie Here, the raw mixture is ground in a vertical mill The gasses however goes through the 3Raw Mill, Ducting Complex Gas Conditioning (Cement

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

The strategy has been successfully implemented in 33 cement grinding mills and 6 raw grinding mills in a number of cement plants in America and Canada The feedback received from the plants has shown increases in production and reduction in specific energy consumptionCement and Raw Mill Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power consumption HURRICLON® , installed after the mill classifier, again proves to be the best technology for the mill product collection, providing top separation Cement and Raw Mill A TEC Innovative Technologies for Cement mill (cement ball mill) is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics, etc in cement plant, cement grinding station and other cement industries Cement mill can grind ore or other materials by wet process or by dry Cement mill,Cement mill price,Raw material mill,China

Raw Mill In Cement Plant Equipment Manufacturer Buy Raw

Raw mill is used widely for grinding (both drying and grinding) cement raw material and other materials in buinding material, metallurgical, electric and chemical industries Sorts and features: Common raw mill: It is used for small mediumsized raw materials grinding system which generally is cycle flow system with material separating system 13 rows Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary Raw Mill,Raw Mill In Cement PlantDec 16, 2013 Lafarge Canada Inc is Canada's largest cement company, with slightly less than onethird of the nation's capacity The next 2 largest producers, St Lawrence Cement Inc and St Mary's Cement Co, combine to account for an additional 37% of Canada's capacity Canadian cement plants tend to be modern and larger than other North American facilitiesCement Industry The Canadian Encyclopedia

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

The strategy has been successfully implemented in 33 cement grinding mills and 6 raw grinding mills in a number of cement plants in America and Canada The feedback received from the plants has shown increases in production and reduction in specific energy consumptionNatural Resources Canada's Office of Energy Efficiency Leading Canadians to Energy Efficiency at Home, at Work and on the Road FOREWORD With support from Natural Resources Canada (NRCan), the Cement Association of Canada (CAC) commissioned an energy benchmarking study of Canada's Portland grey cement industry in 2007The study builds on other sector benchmarking initiatives CANADIAN CEMENT INDUSTRY ENERGY BENCHMARKING Inside, at 1400 degrees C, the raw material is transformed into clinker: small, dark gray nodules 34 centimeters in diameter 9 Cement milling The clinker is ground by differentsize steel balls while it works its way through the mill’s two chambers, with gypsum being added to extend cement setting times 10 Cement packaging and shippingCement Plant Great Wall Corporation

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsHowever, new cement kilns are of the 'dry process' type Dry process kilns In a modern works, the blended raw material enters the kiln via the preheater tower Here, hot gases from the kiln, and probably the cooled clinker at the far end of the kiln, are used to heat the raw meal As a result, the raw meal is already hot before it enters the The cement kilnRawmill Wikipedia, the free encyclopedia A medium sized dry process roller mill A rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement 1970 the situation has changed dramatically, and new wet process plant is now rarely installedraw mill process in cement plant

How Cement Is Made HeidelbergCement Group

The desired raw mix of crushed raw material and the additional components required for the type of cement, eg silica sand and iron ore, is prepared using metering devices Roller grinding mills and ball mills grind the mixture to a fine powder at the same time as drying it, before it is conveyed to the raw meal silos for further homogenisationShree Cement places order with Gebr Pfeiffer for raw mills, cement mills and mills, enabling the plant to keep a pool of shared spare parts Read more Cement In the cement manufacturing industry, limestone or dolomite raw materials for the production of raw mill feed and also in the pregrinding of cement clinkerparts of raw mill in cement plantThe course content will be suitable for a wide range of personnel within a cement manufacturing company including junior/middle management, technicians, production and control room staff, etc and also for others who wish to gain a comprehensive understanding of the complete cement Cement Manufacturing Technology Course

Any of your enquiry will be highly appreciated.

Enquiry Now