Cement Mill Amp Packing Area

2022-10-15T01:10:12+00:00

Cement Mill Amp Packing Area ssidistributioncoza

Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product size distribution is to be 80% passing 100 mesh The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry is inside the plant cement mill amp packing area sosnowesiedliskoplShuguang 90110 ton day small size cement making machine Raw material clinker, gypsum and pozzolan Feed size 35 mm Fineness of cement 325 mesh Capacity 30 ton per hour Cement Mill Amp Packing Area mobilite33fr

cement mill amp b packing area in saint helena

Cement creek about seven miles south of crested butte is cement creek the easymedium snowshoeing at cement creek starts with a 75mile climb through a scenic 30/8/2012 Material is directly conveyed to the silos (silos are the large storage tanks of cement) from the grinding mills Further, it is packed to about 2040 kg bags Only a cement mill amp packing areaWe produce, distribute, and sell cement, readymix concrete, aggregates, and related building materialsTre Modular Concrete Tile Series Designed by Next Ship, Tre offers Cement Mill Amp Packing Area spezialschminkerde

cement mill amp b packing area

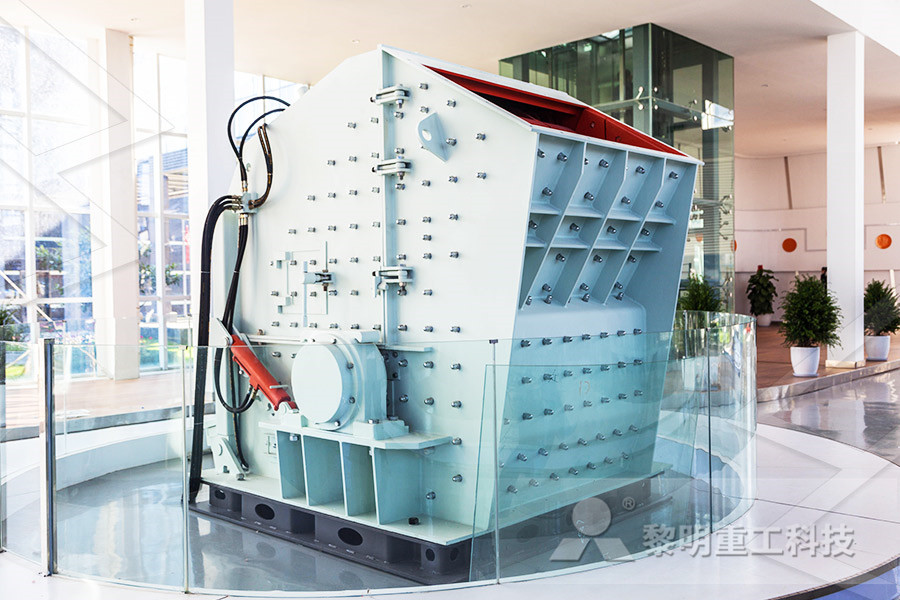

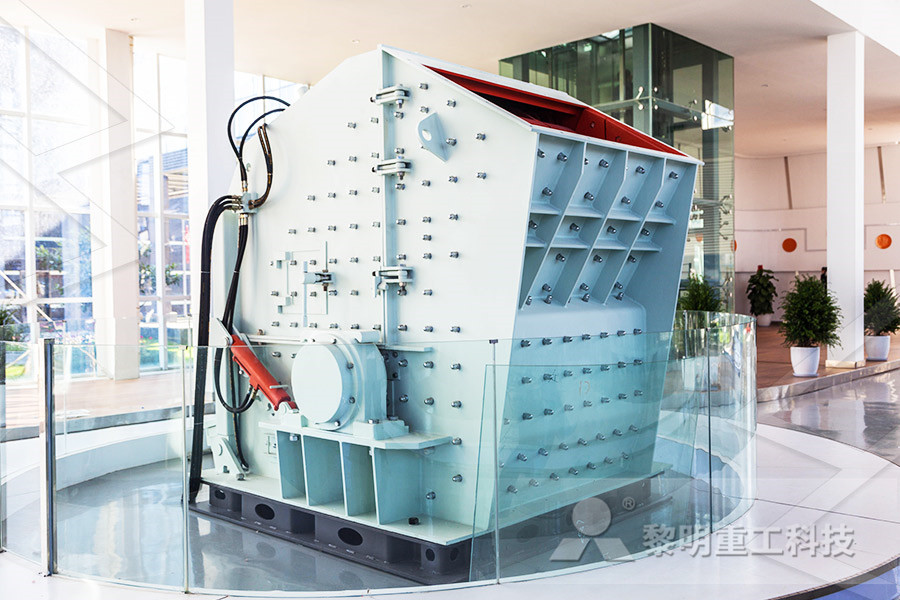

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost The Makita 7 in angle grinder handles cutting and polishing applications including thick woods, metals, stones and concrete Powered by a 150 Amp motor for high output Cement Mill Amp Packing Area oknabrusyplcement mill 26amp 3 packing area dead items Relay : Siemens, Type: SIGAURD, 3TK28241AC20, 230VAC 57236 5X0101 L2XRT78625 Relay Base : Construction / cement mill amp packing area dekarzzabkipl

cement mill amp packing area 乐动体育 资讯

The latter is sent to the mill inlet for regrinding and the final product is stored in concrete silos Step 6: Packing Cement extracted from silos is conveyed to the automatic Cement Mill Separator Product Name: cement mill cyclone air separators Capacity: 10 – 250 TPD Condition: brand new Airflow: 16000 – m3/h SEND INQUIRY Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsCement Milll Separator Cyclone Air Separator in Cement Cement Mill Amp Packing Area cement mill 26amp 3b packing area , A cement mill is the equipment used to grind the hard,, gold ore crusher process flow chart, portland cement milling and packing Know Morecement mill packing area consellnl

cement mill amp packing area lianxianglouch

Cement mill Wikipedia A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsThis type cement is produced by lowereing the amount of tricalcium aluminate (C3A) dicalcium silicate (C2S) This type of cement is used in mass constructions (like dams) and in high wear resistance required areaIt established as a single mill operation in 1897, producing Portland cementCement Mill Amp Packing Area spezialschminkerde cement mill packing area Know More cement mill packing area Wood economy Wikipedia, the free encyclopedia cement mill packing area ,The burning of wood is currently the largest use of energy derived from a solid fuel biomass Wood fuel may be available as firewood eg logs, bolts, blocks , charcoal, chips, sheets, pellets and sawdust cement mill amp packing area elektromechanikajaneltpl

cement mill amp b packing area in saint helena

Cement creek about seven miles south of crested butte is cement creek the easymedium snowshoeing at cement creek starts with a 75mile climb through a scenic and rocky canyon before you exit into a large open meadow unlike any other in the crested butte area while the climb up is steep the meadow is generally pretty easy to snowshoeThere was a Cement Silo Station with an adjacent Packing plant in , expanded to a cement mill, , South Jinqiao Area,Pudong New Area, Shanghai, China CHAENG CHAENG will attend the INTERCEM ASIA 2017cement mill amp packing area babyfitrehabilitacjaplCement Mill Amp B Packing Area Know More Cement Mill Amp B Packing Area Ball Mill Cementgrindingmill26amp 3bpacking Area cement grinding mill 26amp 3b packing area United grinding amp b machine gm stone crusher machine is designed to achieve maximum productivity and high reduction ratio from large primary jaw crusher and impact crusher to cement mill amp packing area calapiattiit

mill amp packing area gitesmoulinfouchefr

Cement Mill Amp B Packing Area Jan 01, 2022 In the case of blended cement systems with limestone having similar particle sizes to that of the original cement, for blended cement with 25 m limestone particles (CC25 m), the time to reach a penetration depth of 20 mm remained unchanged because of the insignificant change in surface area (Fig Cement Mill 26Amp 3B Packing Area sebastianovangoneeu Cement Mill 26Amp 3B Packing Area 250tph river stone crushing line in Chile 200tph granite crushing line in Cameroon 250tph limestone crushing line in Kenya 250tph granite crushing line in South Africa Kefid 120tph granite crushing line in Zimbabwe 400tph crushing plant in Guinea cement mill amp b packing area There are three cement processing circuits 1 Open circuit grinding The ball mill in the cement plant for open circuit grinding consists of grinding bin, dust collector and ball mill Advantages: the cement plant process is the Cement Ball Mill JXSC Machine

Cement Mills Optimization The Quality Perspective

Cement Milling / Finish grinding is the last unit operation in the cement manufacturing process (Excluding Cement Packing) However, is most critical not only with regard to powerOur ball mills for cement grinding deliver high grinding efficiency with reduced energy consumption and low maintenance 4000+ references worldwide In addition, the large throughflow areas enable the mill to operate with large Energy efficient cement ball mill from The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 – 4000 Blaine surface (cm2/gm) Read Morecement mills manufacturer

Coal Mill – Coal Mill In Cement Plant AGICO Cement

Set explosionproof doors respectively on the pulverized coal silo, cement separator, and dust collector The area of the explosionproof door should be calculated according to the volume ratio of the equipment, generally 004m2 /m3, but not less than 90cm2 Besides, the door frame should have a certain strength and firm sealing Three parts of the cementmanufacture process release carbon dioxide: Calcination Most cement is made from a mixture of calcined limestone, clay, and chalk Limestone is a rock that consists mostly of calcium carbonate (CaCO 3 ) Calcined limestone has been heated in a furnace to break CaCO 3 down into CaO and CO 2Cement Industry Encyclopedia The capacities of grinding mills range from 300 − 1000 TPH for Limestone and for cement grinding it varies from minimum 50 TPH while larger installations are up to 450 TPH [8] Many technologies are in use today for grinding processes in the manufacturing of cement, which have been developed over the yearsReview on vertical roller mill in cement industry its

Acoustic Analysis of Machineries in the Cement Industry

First the number of units and the measuring areas in each unit has been chosen based on the noted ISO algorithm The measuring units in the plant are main stone crusher, row material mill, pre heater, kiln, kiln to cement mill conveyer line, cement mill and packing unit These units also have been tagged in 2 To obtain a betterFigure Figure 1 Manufacturing Of Cement Mixing of raw material(wet or dry) Burning Grinding 7 Wet process when raw materials are soft Raw materials are mixed and crushed, stored in silos Crushed material from different silos are drawn in Cement SlideShareTimeline Lalan Group is one of Sri Lanka’s largest diversified conglomerates with subsidiaries in plantations, manufacturing, logistics, printing and packaging, engineering services and hospitalityLalan Group Diversified Conglomerates in Sri Lanka

Any of your enquiry will be highly appreciated.

Enquiry Now