magnetic seperator for tin metal process

2019-11-25T00:11:31+00:00

Tin reduction process of magnetic prominetech

Tin reduction process of magnetic tailings flotation 121020; 3 Views; icon 0; In the ball mill grinding process, the raw ore is ground to 0074mm, accounting for 60%, and the magnetic separator is used for magnetic rough separationThe magnetic field strength is 96kA/m The obtained coarse concentrate is reground to 0045mm, accounting for 787 %, the iron ore produced by magnetic Whether you’re responding to a metal contaminant situation, or positioning yourself to avoid metal contamination and recalls, incorporating MAGNATTACK ™ magnetic separators is a smart and efficient addition to your powder processing system Each MAGNATTACK ™ item has superior design elements to provide the best product protectionMAGNATTACK™ Magnet Separators Powder ProcessSolutionsMagnetic Separation We make permanent Magnetic Separation Equipment for any application, suitable for almost any industry; Metal Detection Designed to monitor gravityfed products, pneumatically conveyed materials on belts, liquids and slurries in pipes; Material Handling Equipment A large lineup of material handling equipment for the Recycling, Metal Stamping, Plastics and Food industriesMagnetic Separation Equipment Magnetic Separators

magnetic seperator for tin metal process in brazil

magnetic seperator for tin metal process in brazil We are here for your questions anytime 24/7, welcome your consultation Get Price 702 tin ore magnetic separator products are offered for sale by suppliers on of which mineral separator accounts for 91 A wide variety of tin ore magnetic separator options are available to you such as newAs a Africa Egypt Tin / Coltan Processing Machine / Belt Type Threedisc Electromagnetic Separator is a Dry Intensified Magnetic Separator/High Intensity Magnetic Separator, applicable for separations of tin, tungsten, tantalumniobium, ilmenite, rare earth ore, chromite ores, limonite, columbium, zircon, rutile, monazite, andalusite, garnet, kyanite, feldspar, quartz and other minerals with magnetic separator tin systemwallnlAusmelt Tin Magnetic Separatormagnetic Separator Milliconecrusher dry magnetic separator tin ore dry magnetic separator tin ore china mining equipment co ltd sidebar in the 1800s tin was an ordinary material particularly popular with the working class because of its low cost and bright luster dry magnetic separator manufacturers aggregate production dry process ball mill for dry grinding dryTin Process Equipments For Tin Ore Separator

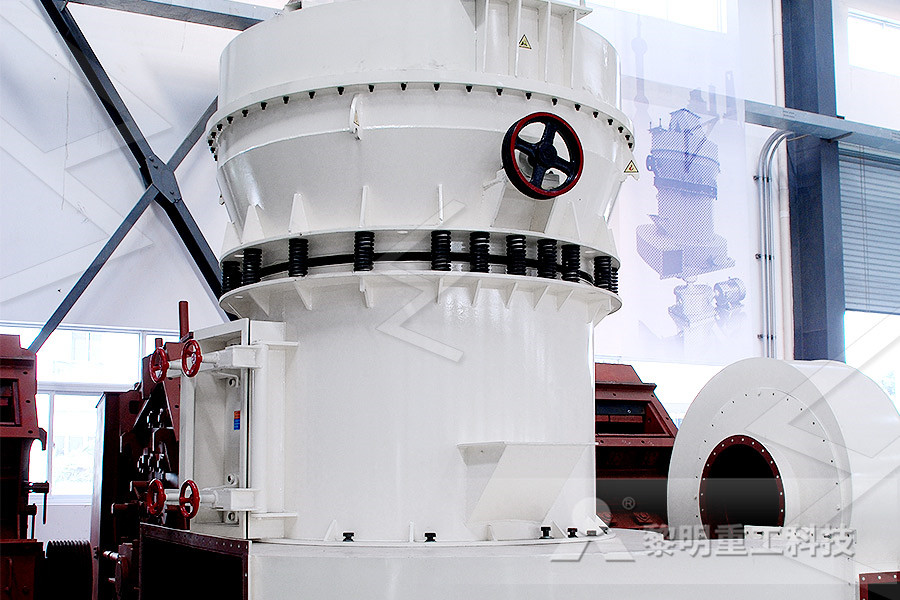

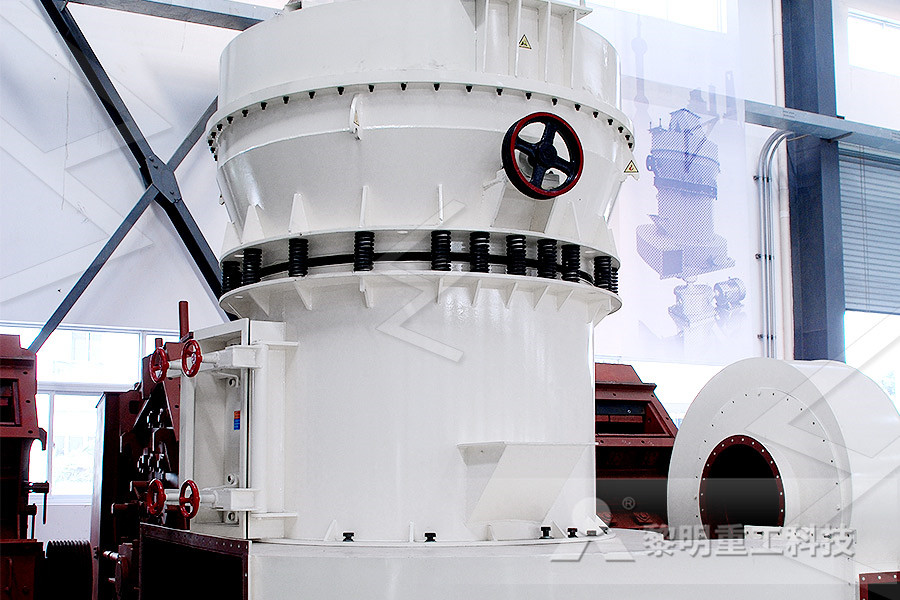

MAGNETIC SEPARATORS

A magnetic separator generating a high magnetic force of 26 T (26000 G) Used for weak magnetic substances which cannot be removed suffi ciently by a standard separator Aluminum items can be sorted and separated from noncombustible wastes and large crushed wastes effi cientlyMagnetic separation is the process of separating components of mixtures by using magnets to attract magnetic materials The process that is used for magnetic separation detaches nonmagnetic material with those that are magnetic This technique is useful for not all, but few minerals such as ferromagnetic (materials strongly affected by magnetic fields) and paramagnetic (materials that are Magnetic separation Wikipediamaterials and semifi nished products are called magnetic separation Kanetec off ers a wide variety of magnetic separators for use with lump materials, bulk materials, claylike materials and liquids A magnetic separator MAGNETIC SEPARATORS

Lims magnetic separators

Low intensity magnetic separators, Lims, are designed to recover magnetic material from nonmagnetic matter The separators are of modular design with several frames and process tank designs using a common magnetic Magnetic Separation We make permanent Magnetic Separation Equipment for any application, suitable for almost any industry; Metal Detection Designed to monitor gravityfed products, pneumatically conveyed materials on belts, liquids and slurries in pipes; Material Handling Equipment A large lineup of material handling equipment for the Recycling, Metal Gravity FreeFall Style Metal Separators – Recycling and Magnets are a key components in a powder process to ensure reliability, safety of the installation and safety of the product Magnetic separators allow to remove metal contaminants from bulk solids Magnet traps / metal separator for powder flow A guide

Tin Process Equipments For Tin Ore Separator

Ausmelt Tin Magnetic Separatormagnetic Separator Milliconecrusher dry magnetic separator tin ore dry magnetic separator tin ore china mining equipment co ltd sidebar in the 1800s tin was an ordinary material particularly popular with the working class because of its low cost and bright luster dry magnetic separator manufacturers aggregate production dry process Magnetic seperator for tin metal process dray magnetic separator ore tin catalog Dray Magnetic Separator Ore Tin alog process crusher Get Price Wet low intensity magnetic separators Wet low intensity magnetic separators Iron ore processing General has produced several thousand Low In The magnetic separation dray magnetic separator ore tin alogNov 01, 2019 Effect of roasting parameters on the separation of tin during the calcium roasting followed by a magnetic separation process (tin content in magnetic materials) Table 4 Results New understanding on the separation of tin from magnetite

Electromagnetic Separation Of Tin Ores

Magnetic seperator for tin metal process,Tin ore the standard processing technique of tin ore is gravity separation As time goes by, magnetic separation seems within the tin ore processing plant Read more ore particles magnetic separationLow intensity magnetic separators, Lims, are designed to recover magnetic material from nonmagnetic matter The separators are of modular design with several frames and process tank designs using a common magnetic Lims magnetic separators Magnetic system is compounded of ferrite and permanent magnets; the average magnetic induction intensity of cylinder surface is 100~600mT The same cylinder can be equipped with three types of tank adapting to different dressing process Small area taken, good separation for magnetic mineral, reduce the load of next processEquipment Manufacturer of Magnetic Separator, Magnetic

Magnetic Separator Miningpedia

Dry or Wet Magnetic Separator? As a common beneficiation process, magnetic separation process separate minerals based on their magnetic difference, which widely used in the separation of black metals, nonferrous metals and rare metal Magnetic seperator for tin metal process dray magnetic separator ore tin catalog Dray Magnetic Separator Ore Tin alog process crusher Get Price Wet low intensity magnetic separators Wet low intensity magnetic separators Iron ore processing General has produced several thousand Low In The magnetic separation dray magnetic separator ore tin alogGravity Mining Diaphragm Mineral Jigger Separator For Metal Process Plant , Find Complete Details about Gravity Mining Diaphragm Mineral Jigger Separator For Metal Process Plant,Magnetic Separator For Magnetic Metal Separation,Multi Gravity Separator For Gold Ore Mineral,Diaphragm Mineral Jigger Separator Gravity Mining Diaphragm Mineral Jigger Separator For

Gravity FreeFall Style Metal Separators – Recycling and

Magnetic Separation We make permanent Magnetic Separation Equipment for any application, suitable for almost any industry; Metal Detection Designed to monitor gravityfed products, pneumatically conveyed materials on belts, liquids and slurries in pipes; Material Handling Equipment A large lineup of material handling equipment for the Recycling, Metal “Magnetic Separation Technology is the most important technology for any recycling industry” Magnetic Separation is the process, in which the “magnetically caused material is detached easily” by using a magnetic force From last many years, magnetic separators are used for various separation process Magnetic Separation Technology For A Recycling IndustryExtraction of tin consists of three parts, ie tin ore concentration, smelting and refining Cassiterite is the main source of tin ore, with specific gravity of 687g/cm 3, density larger than most of gangueTherefore, 90% of tin concentrate is mainly obtained from cassiterite through gravity separationExtraction of Tin/ StannumTin Metalcess

China Magnetic Separation, Magnetic Separation

China Magnetic Separation manufacturers Select 2020 high quality Magnetic Separation products in best price from certified Chinese Mining Separator manufacturers, Mineral Separator suppliers, Jan 23, 2017 Magnetic separation process can be of either the belttype or the drumtype In the drum type process, a permanent magnet is located inside a rotating shell Material passes under the drum on a belt A belt separator is similar except that the magnet is located between pulleys around which a continuous belt travels Magnetic separation process Steel Scrap and Scrap Sorting and Preparation Processes When you need magnetic separation the Reading range of magnetic separators has a wide range of proven, cost effective products Including wet high intensity, induced roll, rare earth roll, rare earth drum, low intensity and medium intensity magnetic separators the Reading range has a magnetic Magnetic Separation Mineral Technologies

Magnetic Separators, Separation Equipment Plates, Grates

Magnetic Separation equipment is used to remove ferrous tramp metal contaminants from dry particulate, liquids, and slurries in the process of grain, feed, sugar, cereal, chemical, mineral,

Any of your enquiry will be highly appreciated.

Enquiry Now