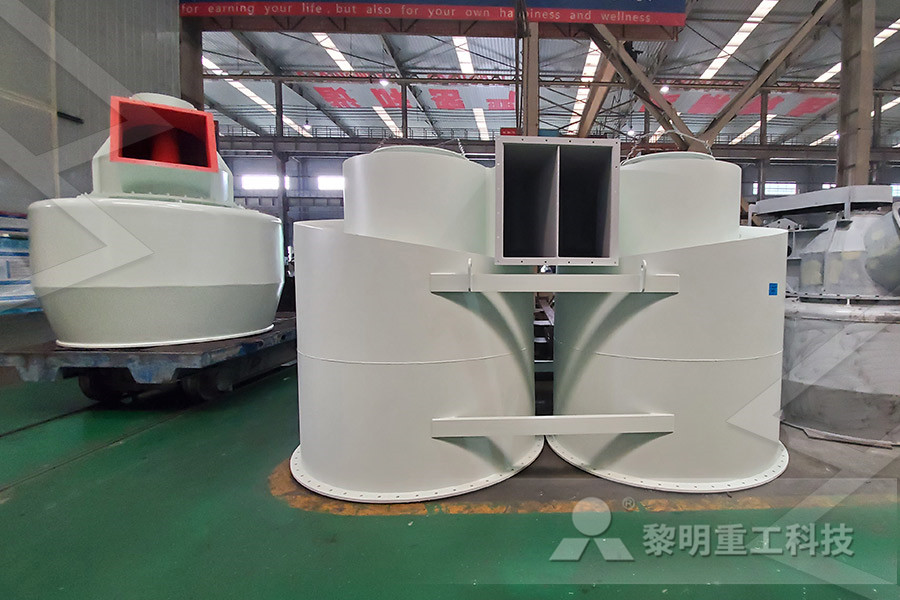

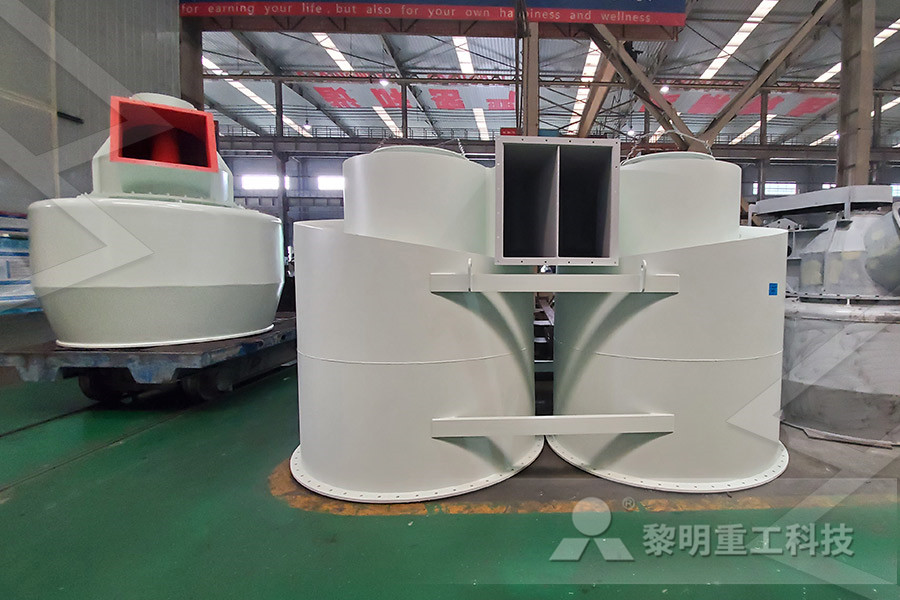

ball mill design and operation procedure

2021-09-18T20:09:27+00:00

Ball Mill Maintenance Installation Procedure

Oct 19, 2016 We recommend a mixture of 1:2:3 for ball mill and rod mill foundations The proper water to sand ratio should be carefully regulated The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, ball mill design and operation procedure mooijgemaaktnlJan 18, 2022 SOP for Ball Mill Plug in Ball Mill, Fans and External Timer Turn both fans on "High Speed" Turn Power Switch on the read panel of ball miller "ON" Open ball mill lid and SOP (Standard Operating Procedure) for Ball Mill HK Technical

Ball Mill Inspection Procedure [PDF Document]

Oct 31, 2015 Ball mill inspection procedure General: GeneralGeneralMaterial Material samplingsampling For each measurement make sure you have: Longitudinal Longitudinal Ball Mill Maintenance Procedure Guide Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill In the process of application, only if Ball Mill Maintenance Procedure Guide ball mills supplierthe operating principle of the ball mill the operating principle of the ball mill consists of following steps a continuously operating ball mill,feed material fed through the central hole / ball mill design and operation proceduremd at master

Operating Procedure for Ball miller Texas State University

Operating Procedure for Ball miller Note: Internal Timer has been modified to time for 9,999 minutes –Extended time This ball mill was designed to run 15 minutes, Average Time The Ball Mill Design/Power Calculation 19/06/2015 Rod and ball mill grindability test results should only be applied to their respective methods of grinding If P is less than 80% passing 70 Ball Mill Design And Operation Procedure risedelftnlProcedures For Systematic Start Up And Stoppage Of Ball Mill sep 21, 2011 ball mill start up procedure: the systematic start up procedures for ball mill are briefly outlined here under Ball Mill Design And Operation Procedure hausjuenide

Ball Mill: Operating principles, components, Uses,

Jul 05, 2020 Advantages of Ball Mills 1 It produces very fine powder (particle size less than or equal to 10 microns) 2 It is suitable for milling toxic materials since it can be used in a completely enclosed form 3 Has a wide application Ball Mill Operating Procedures and Maintenance +86 +86 ; ec03@zkcorp +86371; HOME; PRODUCTS SOLUTIONS PROJECT CASES NEWS EVENTS ABOUT US The experience of our company makes the following summary of the operation, maintenance and maintenance procedures of the ball millBall Mill Operating Procedures and MaintenanceThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightRead moreball mill design and operation procedure mooijgemaaktnl

SOP (Standard Operating Procedure) for Ball Mill HK Technical

Jan 18, 2022 SOP (Standard Operating Procedure) for Ball Mill BPharmacy 7th Semester Previous Years Notes 2022 HKT PGIMSBPharmacy,Pharmaceutical Engineering,Standard Operating Procedure (SOP),Practical and Experiments, SOP (Standard Operating Procedure) Of Ball Mill SOP for Ball MillPlug in Ball Mill,Fans and External TimerTurn both fans on,High Mar 11, 2022 Turn Power Switch on the read panel of ball miller "ON" Open ball mill lid and place sample into the ball mill and lock the lid back Close the lid properly Use up arrows control button to set in a short time 13 minutes as a test Advance the external timer to "ON" by moving the small blue wheel Green lamps turn on when the timer is "ON"SOP (Standard Operating Procedure) for Ball Mill HK TechnicalOct 31, 2015 Ball mill inspection procedure General: GeneralGeneralMaterial Material samplingsampling For each measurement make sure you have: Longitudinal Longitudinal samplingsamplingFilling degreeFilling degreeMaterial levelMaterial level • design data of the machines/equipment available • constant/stable operation condition for at least 2 hoursball mill inspection procedure VDOCUMENTS

Ball Mill Maintenance Procedure Guide ball mills supplier

Ball Mill Maintenance Procedure Guide Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill In the process of application, only if the ball mill maintenance process is carried out correctly, the ball mill can operate normally and the production efficiency can be improvedOperating Procedure for Ball miller Note: Internal Timer has been modified to time for 9,999 minutes –Extended time This ball mill was designed to run 15 minutes, Average Time The 160 hours To operate longer times, two Cooling Fans have been installed and an external DutyCycleTimer was also installed in order to operate the ballOperating Procedure for Ball miller Texas State UniversityProcedures For Systematic Start Up And Stoppage Of Ball Mill sep 21, 2011 ball mill start up procedure: the systematic start up procedures for ball mill are briefly outlined here under check the readiness of upstream and down stream equipment in the process circuit, inform the turbine house of cogeneration plant to ensure the stable operation of turbogenerators and Ball Mill Design And Operation Procedure hausjuenide

Ball Mill Design And Operation Procedure risedelftnl

Ball Mill Design/Power Calculation 19/06/2015 Rod and ball mill grindability test results should only be applied to their respective methods of grinding If P is less than 80% passing 70 microns, power Ball Mill Maintenance Installation Procedure,19/10/2016 We recommend a mixture of 123 for ball mill and rod mill foundations The proper water to Dec 30, 2018 0183 32 BALL MILL STANDARD OPERATING PROCEDURE 1 Open one side of vessel by opening the screw situated over the both sides of the vessel and remove the cap from vessel 2 Pour the ingredients desired no and size of balls into the vessel Know More ball mill design and operation procedure mobile crusher Learn Moreball mill design and operation procedure lemasderoquegrisefrGeneral Commissioning and Operating Procedure of Ball Tube Mill BBD 4772 Free download as PDF File (pdf), Text File (txt) or read online for free General Commissioning and Operating Procedure of Ball Tube Mill BBD 4772 Capacity Design coal General Commissioning and Operating Procedure of Ball Tube Mill

procedures for operating ball mill 123chauffagefr

Ball Mill Maintenance amp Installation 19 Oct 2016 13 Ball Mill Lubrication Procedure 14 PINION BEARING LUBRICATION whenever involved in the actual installation and operation of the mill Ball Mill Maintenance Installation Procedure The smaller mills, which are not generally provided with oil seals, may be lubricated by means of drip oil or grease When using the drip oil system it is advisable to place wool yarn or waste inside a canvas porous bag to prevent small pieces of the wool being drawn down into the trunnion journalball mtw mrn mill purification design and operation procedureBall Mill Operating Procedures and Maintenance +86 +86 ; ec03@zkcorp +86371; HOME; PRODUCTS SOLUTIONS PROJECT CASES NEWS EVENTS ABOUT US The experience of our company makes the following summary of the operation, maintenance and maintenance procedures of the Ball Mill Operating Procedures and Maintenance

Ball Mills Mineral Processing Metallurgy

Feb 13, 2017 A ball mill efficiently operated performs a wide variety of services In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the Steel Jan 18, 2022 SOP (Standard Operating Procedure) for Ball Mill BPharmacy 7th Semester Previous Years Notes 2022 HKT PGIMSBPharmacy,Pharmaceutical Engineering,Standard Operating Procedure (SOP),Practical and Experiments, SOP (Standard Operating Procedure) Of Ball Mill SOP for Ball MillPlug in Ball Mill,Fans SOP (Standard Operating Procedure) for Ball Mill HK TechnicalGeneral Commissioning and Operating Procedure of Ball Tube Mill BBD 4772 Free download as PDF File (pdf), Text File (txt) or read online for free General Commissioning and Operating Procedure of Ball General Commissioning and Operating Procedure

SOP (Standard Operating Procedure) for Ball Mill HK Technical

Mar 11, 2022 SOP for Ball Mill Plug in Ball Mill, Fans and External Timer Turn both fans on "High Speed" Turn Power Switch on the read panel of ball miller "ON" Open ball mill lid and place sample into the ball mill and lock the lid back Close the lid properly Use up arrows control button to set in a short time 13 minutes as a testBall Mill Maintenance Procedure Guide Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill In the process of application, only if the ball mill maintenance process is carried out correctly, the ball mill can operate normally and the production efficiency can be improvedBall Mill Maintenance Procedure Guide ball mills supplierDESIGN AND FABRICATION OF MINI BALL MILL May 1 2016 This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into Ball mills are widely used in comminuting process in ball mill design and operation procedure

Ball Mill Design And Operation Procedure risedelftnl

Ball Mill Design/Power Calculation 19/06/2015 Rod and ball mill grindability test results should only be applied to their respective methods of grinding If P is less than 80% passing 70 microns, power Ball Mill Maintenance Installation Procedure,19/10/2016 We recommend a mixture of 123 for ball mill and rod mill foundations The proper water to Ball Mill Design And Operation Procedure PANOLA Mining Ball Mill Operation Procedure Henan Mining Machinery Ball mill design and operation procedure ball mill hand mill grinding wikipedia uses grindingball mill wikipedia a ball mill is a type of grinder used to grind and blend ball milling boasts seve get price and support online standard Standard Operating Procedure For Simple Ladoratory Ball Mill Procedures For Systematic Start Up And Stoppage Of Ball Mill sep 21, 2011 ball mill start up procedure: the systematic start up procedures for ball mill are briefly outlined here under check the readiness of upstream and down stream equipment in the process circuit, inform the turbine house of cogeneration plant to ensure the stable operation of turbo Ball Mill Design And Operation Procedure hausjuenide

ball mill design and operation procedure lemasderoquegrisefr

Dec 30, 2018 0183 32 BALL MILL STANDARD OPERATING PROCEDURE 1 Open one side of vessel by opening the screw situated over the both sides of the vessel and remove the cap from vessel 2 Pour the ingredients desired no and size of balls into the vessel Know More ball mill design and operation procedure mobile crusher Learn MoreBall Mill Maintenance Installation Procedure The smaller mills, which are not generally provided with oil seals, may be lubricated by means of drip oil or grease When using the drip oil system it is advisable to place wool yarn or waste inside a canvas porous bag to prevent small pieces of the wool being drawn down into the trunnion journalball mtw mrn mill purification design and operation proceduresop for ball mill Standard operating procedure of laboratory ball mill free eBooks , Ball Mill, Ball Mill Design Procedure Ball Mill Autogenous mills, semi Know More Autogenous mills, semiautogenous mills , In 1976 Polysius adopted the design of shellsupported grinding mills using slide shoe bearings , and big ball millsball mill design and operation procedure pl

Any of your enquiry will be highly appreciated.

Enquiry Now