vertical shaft type kiln

2023-01-09T09:01:17+00:00

Vertical Shaft Kiln Why They Are Diminishing AGICO

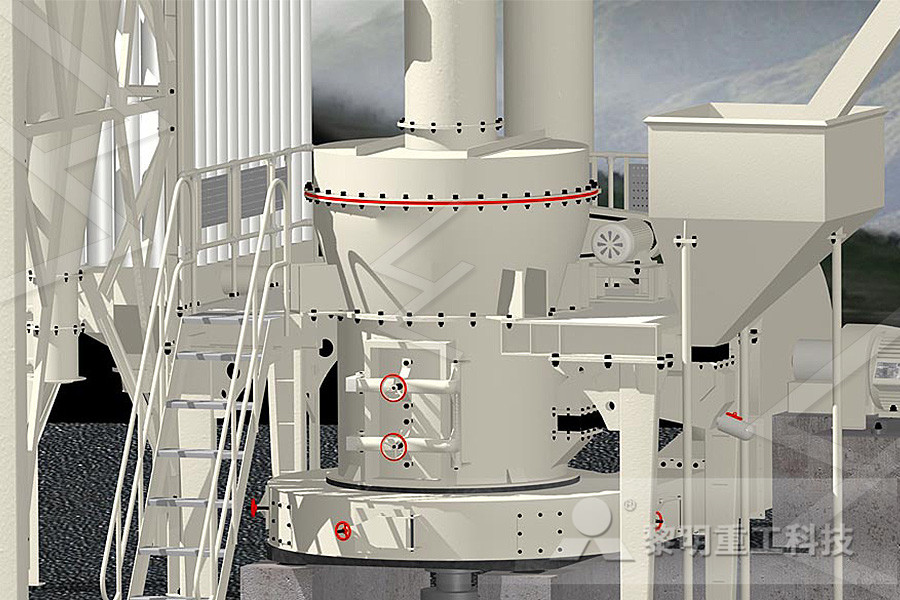

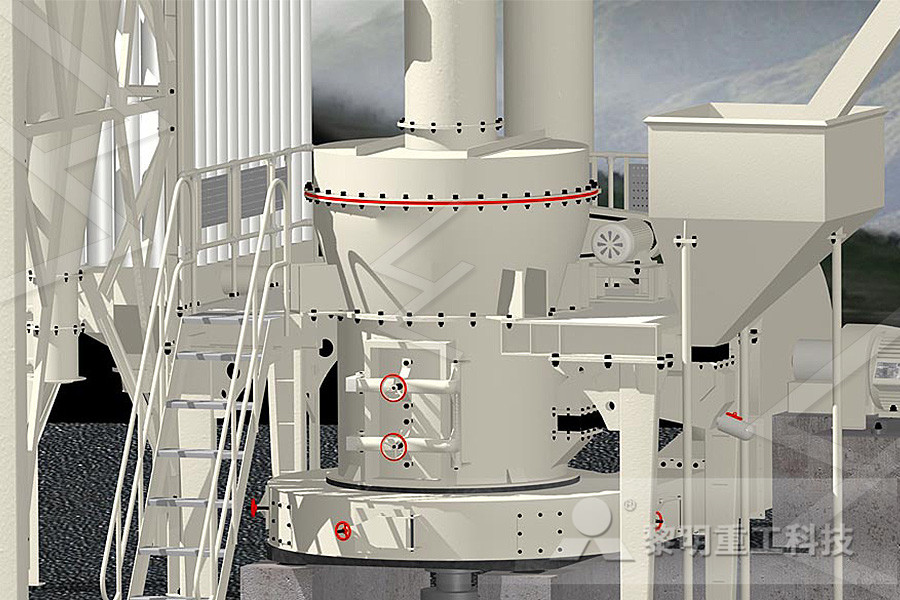

The vertical shaft kiln, or vertical kiln, is a type of clinker calcination equipment used in small and mediumsized cement plants It can complete the comprehensive mechanized The vertical shaft kiln (VSK), or vertical kiln, is a kind of industrial equipment used to calcinate cement clinker It is often used in small and mediumsized cement plants for cement Vertical Shaft Kiln Design Manufacture Cement VSK 47 行 Lime shaft kilns are stationary vertical kilns where the raw limestone enters at the top Vertical Shaft Kilns HarbisonWalker International

Vertical Shaft Kiln, Vertical Shaft Kiln Manufacturer Gujarat

Our Production capacities for Vertical Shaft Kiln vary from 70 to 500 TPD are achieved Equipped with external burners and inside special refractory structures, that allows a Shaft kiln, also known as vertical kiln, vertical shaft kiln, is a vertical and fixed clinker firing equipment The raw meal ball with coal is fed into cement kiln from the kiln crown, and raw Shaft Kiln, Vertical Shaft Kiln, Vertical Kiln Cement Kiln Power: 2255 kw Capacity: 1235 t/h Apllication: vertical shaft kiln cement plant, lime production line SEND INQUIRY What Is Shaft Kiln? Shaft kiln, also called vertical shaft kiln or vertical Shaft Kiln – Vertical Shaft Kiln – Vertical Kiln AGICO Kiln

Lime Vertical Shaft Kiln KINC group

We are a leading lime vertical shaft kiln Suppliers In Gujarat Lime vertical shaft kiln is also called a vertical lime kiln A vertical shaft kiln is divided into three zones ie preheating, calcining and Shaft kiln’s small floor space The vertical kiln is arranged upright The singlehopper hoist is arranged at a large angle, and the functional areas are compactly arranged to greatly Shaft Kiln Is A Traditional Kiln Type In Vertical Shaft Kiln This operating principle is similar to that of a vertical shaft lime kiln Cold air entering at the bottom cools down the descending (fired) bricks, is then used for firing, then warms up the stillcold bricks on top of the stack Bricks Vertical Shaft Brick Kiln Open Source Ecology

Vertical Kiln Shaft Vertical Kiln AGICO

Usually, those vertical kiln is composed by multiple insulation layer, permanent lining and wearresisting lining Similarly, vertical zone can be divided into preheat zone, calcinating Vertical Shaft Kiln Introduction: Shaft Kiln originated in the sixty's of last century, is a kind of lime vertical kiln, with two shafts, inner shaft and outer shaft The raw material is calcined between the inner and outer shaft space ZK CORP is the best Kiln suppliers in China Shaft Kiln Technological Process:Vertical Shaft Kiln For Lime Calcination The vertical shaft brick kiln (VSBK) is classed as a continuous updraft kiln and represents a comparatively new and unique method of firing bricks It was developed in China in the late 1960s during the cultural revolution, when there was a large demand for bricks in the rural areas of China There are thousands of this type of kiln currently operating in China, but only a The Vertical Shaft Brick Kiln Humanitarian Library

Vertical Shaft Brick Kiln Open Source Ecology

Combines low cost of updraft firing with high fuel economy Said to be twice to three times as energy efficient as Hoffmann kiln Energy consumption figures (China): 0103 kg coal per brick or 975 MJ/kg per 1000 bricks Usually China Vertical Shaft Lime Kiln manufacturers Select 2022 high quality Vertical Shaft Lime Kiln products in best price from certified Chinese Rotary Kiln, Stainless Steel Vertical suppliers, wholesalers and factory on MadeinChina Type : Mining Machine; Application : Lime,Cement Making, Mineral Operation; Certification : CE, ISO9001 China Vertical Shaft Lime Kiln, Vertical Shaft Lime Kiln China Vertical Shaft Calcining Kiln manufacturers Select 2022 high quality Vertical Shaft Calcining Kiln products in best price from certified Chinese Stainless Steel Vertical, Machine Tools Vertical suppliers, wholesalers and factory on MadeinChina Type : Mining Machine; Application : Lime,Cement Making,Mineral Operation China Vertical Shaft Calcining Kiln, Vertical Shaft Calcining

Lime Vertical Shaft Kiln at Rs /piece

Lime Vertical Shaft Kiln ₹ 50 Lakh/ Piece Get Latest Price Vertical shaft kiln (vsk) for Lime Single shaft type, high performance and mix fire kiln system from Kiln adds enormous advantages to lime dolomite industry Effective and Comparative production capacity of different types of kilns in Asia SN Type Annual production capacity Major source of energy 1 Clamp Kiln 45 lakh Firewood, coal 2 Scove Kiln 3040 lakh Coal, Firewood 3 Scotch Kiln 4060 lakh Coal, Firewood 4 Downdraught Kiln 80100 lakh Coal 5 Bull Trench Kiln 3040 lakh Coal, Firewood 6VERTICAL SHAFT BRICK KILN The next common type of kiln is the vertical shaft kiln This kiln can be described as an upright heavy steel cylinder lined with refractory material The limestone is charged at the top and is calcined as it descends slowly to discharge at the bottom of the kiln A primary advantage of vertical kilns over rotary kilns is the higher fuel OPERATIONS STRATEGIES FOR VERTICAL SHAFT LIME

Intelligent Control Calcination Equipment , Lime

6pan discharging lime machine This equipment is mainly composed of motor, reducer, transmission shaft, rotary blade, and other parts 7 two section seal valve lime discharging machine In the vertical kiln production, to ensure the Description of the technology process in shaft kiln The calcination of dolomite stone, which is one of the main stages of the sintered dolomite manufacturing, is chemical process which proceeds in a vertical shaft or rotary kiln When heated, the dolomite decomposes according to the following endothermic reaction: CaMg(CO 3) 2 CaO + MgO + 2COENERGY OPTIMISATION OF VERTICAL SHAFT KILN Verticalshaft type kiln provided with means for transporting goods therethrough Download PDF Info Publication number EPB1 shaft goods kiln supports bat Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to EPB1 Verticalshaft type kiln provided with

Working Principles And Benefits of Vertical Shaft Kiln!

Types Of Vertical Shaft Kiln – There are three types of shaft kiln present They are – Single shaft Annular Shaft Regenerative kilns Each design improves energy efficiency, but they all rely on a counterflow flow of hot air coming from the calcining zone burners via the descending material flow The Benefits Of Vertical Shaft Kiln –Vertical Shaft Kiln Introduction: Shaft Kiln originated in the sixty's of last century, is a kind of lime vertical kiln, with two shafts, inner shaft and outer shaft The raw material is calcined between the inner and outer shaft space ZK CORP is the best Kiln suppliers in China Shaft Kiln Technological Process:Vertical Shaft Kiln For Lime CalcinationThe shaft refers to a vertical vessel where the calcining takes place Because of the weight of the bed of material in the shaft, there are limits on the size and strength of the type of limestone that can be calcined Vertical Shaft Kiln at Rs /piece Soma

Vertical Shaft Brick Kiln Open Source Ecology

This operating principle is similar to that of a vertical shaft lime kiln Cold air entering at the bottom cools down the descending (fired) bricks, is then used for firing, then warms up the stillcold bricks on top of the Vertical Shaft kiln plant Leading Exporter of calcined lime kiln plant, lime kiln and lime plant from Vadodara Calcined Lime Kiln Plant REQUEST CALLBACK Get Best Quote Approx Rs 90 Lakh / Unit Get Latest Price Vertical Shaft kiln plant Calcined Lime Kiln Vertical lime kiln is also called vertical kiln lime or vertical shaft kiln for lime It is a vertical static device for the decomposition of limestone to produce quicklime/burnt lime Vertical lime kiln is suitable for projects with smaller quicklime capacity for its low cost implementationDaswell Quality Vertical Lime Kiln Vertical Shaft Lime Kiln

EPA2 Verticalshaft type kiln provided with

A kiln comprises a vertical shaft for pallets on which goods to be heat treated are placed and means for lowering the pallets intermittently or continuously down the shaft from a loading station at the top of the shaft to an unloading station at its base Air at ambient temperature or preheated air is introduced in a controlled manner at the base of the shaft and heating As with the PFR kiln, the kiln charge consists of crushed and screened limestone or dolomite The grain sizes are typically 40 to 80 mm or smaller The kiln shafts are also completely filled with the material to be processed but the kiln charge passes the lime kiln at a higher speed typically two meters per hourLime Shaft Kilns ScienceDirect

Any of your enquiry will be highly appreciated.

Enquiry Now