wet grinding process pdf

2019-08-18T21:08:02+00:00

Wet Grinding [PDF Document]

Dec 31, 2015 1 STERLING ABRASIVES LTD CMYK CMYK GRINDING PROCESS âGrindingâ in simple terms can be defined as a process of abrasion The material is removed by using USA Wet grinding process Google Patents Download PDF Info Publication number USA USA USA USA USA US A USA Wet grinding process Google PatentsMar 27, 2018 Abstract and Figures Comparison of dry and wet grinding process in an electromagnetic mill is presented in this paper The research (PDF) Comparison of Wet and Dry Grinding in

Preparation of nanokaolin by wetgrinding process and

Dec 01, 2021 The wetgrinding treatment was in the following ways: zirconia balls, RKL and water were firstly weighed; afterwards they were put into a selfmade vertical stirred mill (VSM) classified as dry grinding and wet grinding When cutting fluid is spread over the workpiece, wheel face and sides, it is named as wet grinding The commonly used cutting fluid is soda UNIT 2 GRINDING Grinding Indira Gandhi National safety, redundancies and reliable processes Christian Pfeiffer supplies engineering, mills and auxiliary equipment for limestone wet grinding plants in open and closed circuits which are EFFICIENT PROCESSES Wet limestone grinding for FGD

Wet Milling of Cereal Grains USDA

culty, wet mills as a rule process grain of grade No 2 or 3 Only corn and are wet milled today THE OLDEST WETMILLING METHOD for extracting wheat starch is the Halle or Wet VS Dry Grinding and Polishing Bartell Global The choice between wet and dry grinding and polishing is often personal preference Sometimes people will choose to do a bit of both wet grinding process pdfconditions which are dry and wet grinding with every condition is 18 runs of experiments Soluble oil is used at wet grinding The grindability results have shown that while dry grinding THE EXPERIMENTAL STUDY OF EFFECT OF GRINDING

Wet Grinding [PDF Document]

Dec 31, 2015 1 STERLING ABRASIVES LTD CMYK CMYK GRINDING PROCESS âGrindingâ in simple terms can be defined as a process of abrasion The material is removed by using sharp abrasiveThe invention relates to wet grinding and grinders comprising a roller or wheel (4) rolling on a circular track (18) and elastically pressed thereon To enable the rational utilization of this type of grinder for wet grinding, the materials to be ground are subjected to several layer or bed grinding operations During the time in the grinder between two successive FRA1 WET GRINDING PROCESS AND GRINDER FOR How does the wet grinding process work? The wet grinding process, also referenced as wet milling, can be looked at as a series of steps or “unit operations” that are used to manufacture raw materials into a finished product These different stages involve several processes with various procedures that have been laid out and put into placeWet Grinding Process Custom Milling Consulting LLC

Thermal model of the wet grinding process Request PDF

Apr 01, 2000 A thermal model of the wet grinding process is presented The thermal effect of the grain–workpiece interface and the shear plane between the workpiece and the chip is taken into account ByMar 11, 2022 Grinding in the automotive industry can be significantly improved by using wet blasting Wet Blasting can remove multiple layers of coatings and material in a single process For reman, this method eliminates the use of torches for paint removal Improve productivity by retaining or restoring damaged surfaces without wasting excess time and Wet Technologies How to Improve the Grinding Processclassified as dry grinding and wet grinding When cutting fluid is spread over the workpiece, wheel face and sides, it is named as wet grinding The commonly used cutting fluid is soda water Temperature of grinding zone reaches upto 2000 oC in case of grinding of hard materials Use of cutting fluid lowers down the temperature and soUNIT 2 GRINDING Grinding Indira Gandhi National Open

Wet grinding process pdf Manufacturer Of Highend Mining

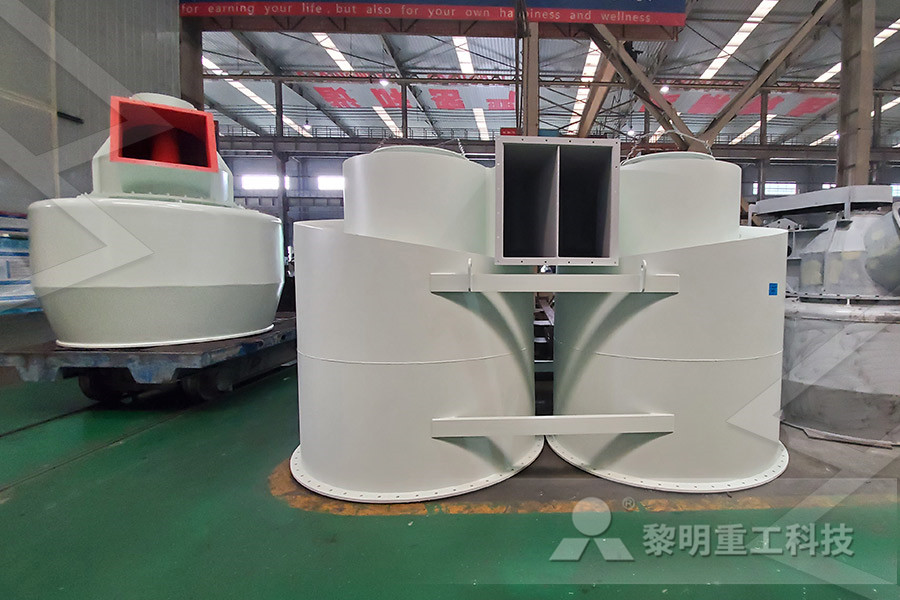

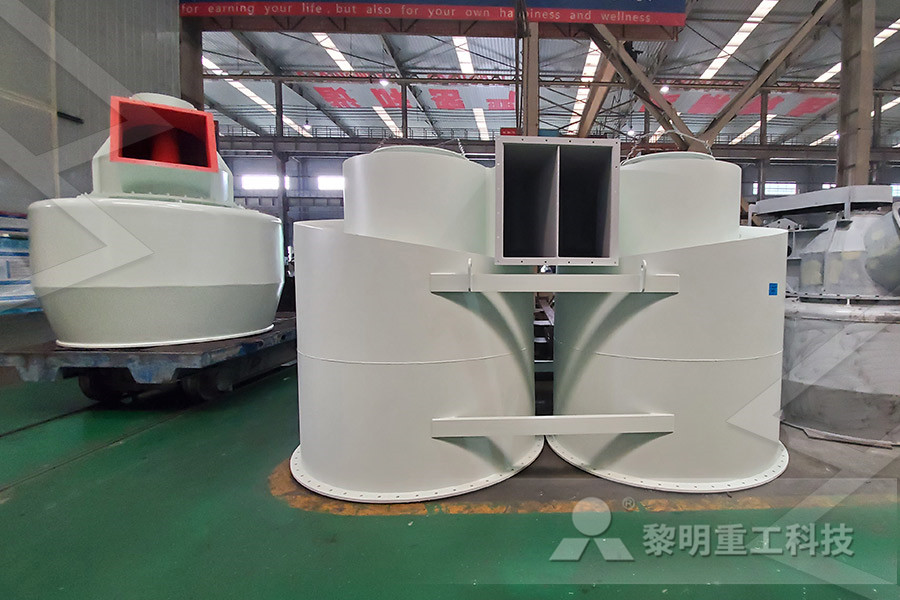

A thermal model of the wet grinding process A thermal model of the wet grinding process A thermal model of the wet grinding process Liao, Y S ; Luo, S Y ; Yang, T H 00:00:00 A thermal model of the wet grinding process is presented The thermal effect of the grainworkpiece interface and the shear plane between the workpiece and culty, wet mills as a rule process grain of grade No 2 or 3 Only corn and are wet milled today THE OLDEST WETMILLING METHOD for extracting wheat starch is the Halle or fermentation process, in which the grain, softened by steeping in water, is ground and made into a mash with water and allowed to ferment a week or two The modified gluten Wet Milling of Cereal Grains USDAsafety, redundancies and reliable processes Christian Pfeiffer supplies engineering, mills and auxiliary equipment for limestone wet grinding plants in open and closed circuits which are optimally suitable for flue gas desulphurisation > optimized, redundant grinding plants (1+1 or 2+1 solutions) > high availability of all componentsEFFICIENT PROCESSES Wet limestone grinding for FGD

wet grinding process pdf

Wet VS Dry Grinding and Polishing Bartell Global The choice between wet and dry grinding and polishing is often personal preference Sometimes people will choose to do a bit of both by starting with wet and switching to dry, but it still won't turn out quite the same because the slurry created by wet grinding is composed of abrasive particles, which will Sep 01, 2011 Wet grinding is generally carried out after complete hydration of the grain that enables the grain to soften ( Jagtap et al, 2008 ) Gowen et al (2007) reported that during the blanching process seed coat of soybean is plasticized, allowing for faster moisture uptake during the subsequent soaking processWet grinding characteristics of soybean for soymilk extraction classified as dry grinding and wet grinding When cutting fluid is spread over the workpiece, wheel face and sides, it is named as wet grinding The commonly used cutting fluid is soda water Temperature of grinding zone reaches upto 2000 oC in case of grinding of hard materials Use of cutting fluid lowers down the temperature and sowet grinding process pdf boulangeriegladboquetfr

[PDF] Comparison of Wet and Dry Grinding in Electromagnetic

Comparison of dry and wet grinding process in an electromagnetic mill is presented in this paper The research was conducted in a batch copper ore grinding Batch mode allows for precise parametrization and constant repetitive conditions of the experiments The following key aspects were tested: processing time, feed size, size of the grinding media, mass of Dec 31, 2015 1 STERLING ABRASIVES LTD CMYK CMYK GRINDING PROCESS âGrindingâ in simple terms can be defined as a process of abrasion The material is removed by using sharp abrasiveWet Grinding [PDF Document]A continuous wet grinding process is disclosed for comminuting material in a liquid, comprising one or more continuous wet grinding line Said continuous wet grinding line comprises (1) two or more sealed wet grinders connected in cascade, (2) no unsealed container connected between said grinders, (3) a positive displacement pump connected before the first sealed wet grinder USA1 Continuous wet grinding process Google

FRA1 WET GRINDING PROCESS AND GRINDER FOR

The invention relates to wet grinding and grinders comprising a roller or wheel (4) rolling on a circular track (18) and elastically pressed thereon To enable the rational utilization of this type of grinder for wet grinding, the materials to be ground are subjected to several layer or bed grinding operations During the time in the grinder between two successive grinding Apr 01, 2000 A thermal model of the wet grinding process is presented The thermal effect of the grain–workpiece interface and the shear plane between the workpiece and the chip is taken into account ByThermal model of the wet grinding process Request PDFMar 11, 2022 Wet Blasting can remove multiple layers of coatings and material in a single process For reman, this method eliminates the use of torches for paint removal Improve productivity by retaining or restoring damaged surfaces without wasting excess time and material You can remove more paint and grunge in less timeWet Technologies How to Improve the Grinding Process

UNIT 2 GRINDING Grinding Indira Gandhi National Open

classified as dry grinding and wet grinding When cutting fluid is spread over the workpiece, wheel face and sides, it is named as wet grinding The commonly used cutting fluid is soda water Temperature of grinding zone reaches upto 2000 oC in case of grinding of hard materials Use of cutting fluid lowers down the temperature and soculty, wet mills as a rule process grain of grade No 2 or 3 Only corn and are wet milled today THE OLDEST WETMILLING METHOD for extracting wheat starch is the Halle or fermentation process, in which the grain, softened by steeping in water, is ground and made into a mash with water and allowed to ferment a week or two The modified gluten Wet Milling of Cereal Grains USDAsafety, redundancies and reliable processes Christian Pfeiffer supplies engineering, mills and auxiliary equipment for limestone wet grinding plants in open and closed circuits which are optimally suitable for flue gas desulphurisation > optimized, redundant grinding plants (1+1 or 2+1 solutions) > high availability of all componentsEFFICIENT PROCESSES Wet limestone grinding for FGD

wet grinding process pdf

Wet VS Dry Grinding and Polishing Bartell Global The choice between wet and dry grinding and polishing is often personal preference Sometimes people will choose to do a bit of both by starting with wet and switching to dry, but it still won't turn out quite the same because the slurry created by wet grinding is composed of abrasive particles, which will affect your processProcess modification have enabled coarser grinds of rock to be used, wet rock grinding can be employed, and agitation power and circulation power is being used more effectively The flexibility of phosphate source is also advantageous to producers WET Process PDF Chemistry MaterialsMay 29, 2022 Grinding Wheel In the grinding process, an emery or corundum wheel is used as the cutting tool Emery and corundum are naturally found abrasives and are impure forms of aluminium oxide Al 2 O 3A grinding wheel is made up of thousands of tiny abrasive particles embedded in a matrix called the ‘bond’ An abrasive is an extremely hard material second in What is Grinding Process? ExtruDesign

Wet Grinding System DJH

It requires lower feed rates and greater reduction in the depth of ach pass This greatly increases the cycle time over wet grinding With wet grinding there is no need to significantly alter the grinding process Dust abatement Dry grinding requires the use of highvolume dust extractors to control the grinding dust coming off the parison of dry and wet grinding process in an electromagnetic mill is presented in this paper The research was conducted in a batch copper ore grinding Batch mode allows for precise parametrization and constant repetitive conditions of the experiments The following key aspects were tested: processing time, feed size, size of the grinding media, mass of the [PDF] Comparison of Wet and Dry Grinding in Electromagnetic classified as dry grinding and wet grinding When cutting fluid is spread over the workpiece, wheel face and sides, it is named as wet grinding The commonly used cutting fluid is soda water Temperature of grinding zone reaches upto 2000 oC in case of grinding of hard materials Use of cutting fluid lowers down the temperature and sowet grinding process pdf boulangeriegladboquetfr

Any of your enquiry will be highly appreciated.

Enquiry Now