wet ball mill balls for mineral processing industry

2022-05-22T07:05:37+00:00

Ball Mill Industry Grinding Mill Mineral Processing

Jul 07, 2020 The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used DOVE Ball Mills are used in supplied and applicable for wet and dry grinding applications within the following branches of industries: Mining, Hard Rock (primary deposit) Gold Mining Application, as well as Platinum base metals, Ball Mill Ball Mills Wet Dry Grinding DOVEJan 30, 2018 Ball Mills 【 Capacity 】 0290 T/H 【Advantages】 Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【 Max Ball Mills Industry Grinder for Mineral Processing JXSC

Ball Mill Balls Grinding Medium used in the Ball Mill for Cement

Feb 21, 2022 Ball mills are suitable for grinding various ores and other materials They are widely used in mineral processing, building materials and chemical industries They can be Wet ball mill and rod mill are commonly used in mineral processing production line, to grind various hardness ore materials Customers who need to grind iron ore, siderite, marble, kaolin, mica, feldspar and other ores have chosen our Ball Mill for Sale Mining and Cement Milling EquipmentWet Ball Mill It is mostly used in the industry production It is to increase the high grinding efficiency under the ball mill grinding and striking, Wear of vibration ball mill in wet Ball Mill Wet Grinding Technology Crusher Mills

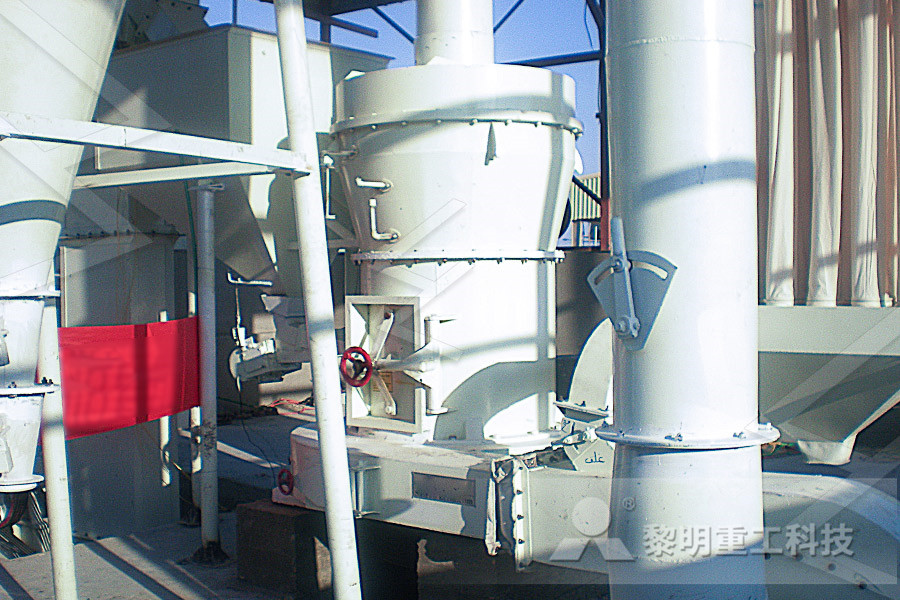

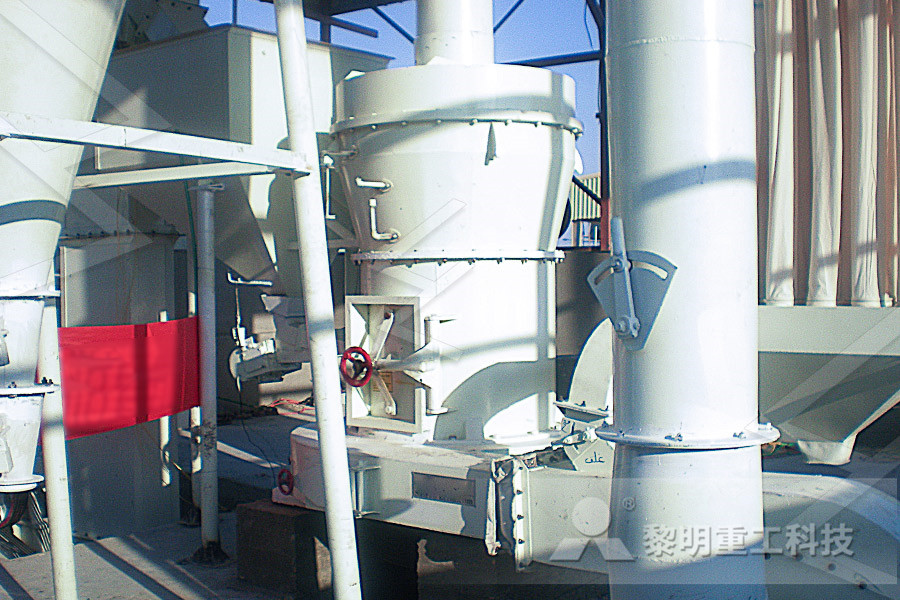

AG SAG Mill for Mineral Processing Wet Ball Mill for

Feeding size: ≤25mm Capacity: 065615t/h Output size: 0074089mm Applications: It is commonly used in the mineral processing industry and ferrous and nonferrous metal ore and nonmetal ore processing plants It can Jul 20, 2022 The wet ball mill has a low noise, and low environmental pollution The wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of a dry ball What Are the Differences between Dry and Wet Type Ball Wet Ball Mill Feeding size: ≤25mm Capacity: 065615t/h Motor power: 1854500kW Applications: It can deal with metal and nonmetal ores, including gold, silver, copper, phosphate, iron, etc The ore that needs to Wet Ball Mill for Metal Ores and Nonferrous Metals

Wet ball mills Yantai Jinpeng Mining equipment, ore

Ball mill is widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush processThe mill consists of feeding device, driving assembly, rotating assembly, Dec 05, 2010 Dec 5, 2010 PRLog wet cement Ball Mill for grinding various ores and other materials, is widely used in mineral processing, building materials and chemical industry can be divided into two kinds of dry and wet grinding methods According to different ways of discharge can be dividedwet cement Ball Mill role in the mineral processing equipmentOct 13, 2022 Wet grinding is economical and more commonly used than dry grinding From the perspective of the overall economic effect of ball mill grinding operations, wet grinding is generally used in mineral processing Wet ball mills are also the most widely used because of their advantages of strong adaptability to materials, continuous dry ball mill mineral processing,the difference between dry ball mill

Ball Mill Wet Grinding Technology Crusher Mills

Wet Ball Mill It is mostly used in the industry production It is to increase the high grinding efficiency under the ball mill grinding and striking, Wear of vibration ball mill in wet grinding at constant Powder Technology Volume 70, Issue 2, May 1992, Pages 153–161 Wear of vibration ball mill in wet grinding at constant temperature TA survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthto AMIT 135: Lesson 7 Ball Mills Circuits – Mining Ball Mill Industry Grinding Mill Mineral Processing The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or largescale beneficiation plant The feed can be dry with a water content of less than 3 to minimize the Ball Mill For For Mineral Processing

Industrial Mineral Processing Sag Mill Grinding Balls

Ag mill and sag mill feeding size 25mm capacity 065615th output size 0074089mm applications it is commonly used in the mineral processing industry and ferrous and nonferrous metal ore and nonmetal ore processing plants it can also be used in cement plant, refractory plant, fertilizer plant and smelting plantBall Mill For Mineral Processing Ball mill machine is widely applied in the industries, such as cement, silicate product, refractory, fertilizer, mineral processing of ferrous and nonferrous metal and glass ceramic, etc It is mainly used to make dry or wet powder grinding of various ores and other grindable materialsballs for mineral processing mills jsdhboskoviceczGrinding Mineral Processing The ball mill rolls grinding media together with the ore, as the ore grinds, these balls initially 510 cm in diameter but gradually wear out Grinding is always carried out under wet conditions, with about 70% solid mixture in water This procedure maximizes ore Grinding Mineral Processing, The ball mill mineral processing and wet ball mill in ore industry

Wet Ball Mill Balls Mineralball Mill grapheneshoppl

Ball Millball Mill Grinding Machinewet Grinding Machine Introduction of ball mill ball mill is a type of grinder used to grind materials into an extremely fine powder mainly for use in the mineral processing industry ball mills can grind various ores and other materials either wet or dry depending on requirements ball mills consist of a large cylinder which Alumina grinding balls for ball mills (Al2O3) have lower abrasion, high hardness, and impact resistance amongst their main characteristics But they’re also costeffective, as they increase grinding efficiency by 4060% (which lets you save energy and money); and ecofriendly, as they do not contaminate the environmentHigh Alumina Ceramic Balls Wet GrindingAMIT 135 Lesson 7 Ball Mills Circuits Mining Mill Wet Ball Mill = kg kWh = 016 A i 0015 033 Dry Ball Mill = kg / kWh = 0023A i 05 Replacement Ball Size Rowland and Kjos proposed the use of their equation for the determination of the initial and replacement media size Chat Online; Energy efficient cement ball mill fromconcrete wet ball mill frankston

Wet Ball Mill for Metal Ores and Nonferrous Metals

Wet Ball Mill Feeding size: ≤25mm Capacity: 065615t/h Motor power: 1854500kW Applications: It can deal with metal and nonmetal ores, including gold, silver, copper, phosphate, iron, etc The ore that needs to Wet ball mills Ball mill is widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush processThe mill consists of feeding device, driving assembly, rotating Wet ball mills Yantai Jinpeng Mining equipment, ore Dec 05, 2010 Dec 5, 2010 PRLog wet cement Ball Mill for grinding various ores and other materials, is widely used in mineral processing, building materials and chemical industry can be divided into two kinds of dry and wet grinding methods According to different ways of discharge can be dividedwet cement Ball Mill role in the mineral processing equipment

dry ball mill mineral processing,the difference between dry ball mill

Oct 13, 2022 (1) Wet ball mill has better performance, higher grinding efficiency, low requirement for ore moisture content, and can process ore with high moisture content and mud content (2) Wet ball mill has less auxiliary equipment and simple material transportation device, so the investment is about 5%10% lower than that of dry ball millBall Millball Mill Grinding Machinewet Grinding Machine Introduction of ball mill ball mill is a type of grinder used to grind materials into an extremely fine powder mainly for use in the mineral processing industry ball mills can grind various ores and other materials either wet or dry depending on requirements ball mills consist of a large cylinder which Wet Ball Mill Balls Mineralball Mill grapheneshopplApr 16, 2021 Angle of nip does not explain the findings In wetbatch ball milling with ore charges from 200 to 35 pounds (about 75 pounds of ore was required to fill the interstices of the balls at rest) and speeds from 30 to 80 percent critical, the slow speed gave the same type of grinding as high speedBall Mill Grinding Metallurgist Mineral Processing Engineer

Ball Mill For For Mineral Processing

Ball Mill Industry Grinding Mill Mineral Processing The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or largescale beneficiation plant The feed can be dry with a water content of less than 3 to minimize the A gupta, ds yan, in mineral processing design and operation, 2006 121 an alkaline slurry from a bauxite grinding mill was scheduled to be classified using a spiral classifier at the underflow rate of 1100 tday the width of the classifier flight was 13 m and the outside diameter of the spiral flights was 12 mIndustrial Mineral Processing Sag Mill Grinding BallsBall Mill For Mineral Processing Ball mill machine is widely applied in the industries, such as cement, silicate product, refractory, fertilizer, mineral processing of ferrous and nonferrous metal and glass ceramic, etc It is mainly used to make dry or wet powder grinding of various ores and other grindable materialsballs for mineral processing mills jsdhboskovicecz

Ball Mill In Polymer Industry

Ball Mills Mineral Processing Metallurgy Feb 13, 2017 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15 x 21 to 8 x 12 Industry Overview Grinding Balls ball mill in polymer industry Sep 02, Grinding in Ball Mills Ball mill ball mill is the key equipment which uses to smash material after it is crushed it is widely used in industries such as cement, silicate products, new building materials, refractory material, fertilizer, mineral processing of ferrous metal and nonferrous metal, glass ceramics, etc it can do the dry or wet grinding for variousGrinding Balls For Ball Mill In Mineral Processing And FilterGrinding Mineral Processing The ball mill rolls grinding media together with the ore, as the ore grinds, these balls initially 510 cm in diameter but gradually wear out Grinding is always carried out under wet conditions, with about 70% solid mixture in water This procedure maximizes ore Grinding Mineral Processing, The ball mill mineral processing and wet ball mill in ore industry

Environmental Protection Ball Mill Machine For Mineral Processing Industry

High quality Environmental Protection Ball Mill Machine For Mineral Processing Industry from China, China's leading Grinding Mill Machine product market, With strict quality control Grinding Mill Machine factories, Producing high quality Environmental Protection Ball Mill Machine For Mineral Processing Industry productsAMIT 135 Lesson 7 Ball Mills Circuits Mining Mill Wet Ball Mill = kg kWh = 016 A i 0015 033 Dry Ball Mill = kg / kWh = 0023A i 05 Replacement Ball Size Rowland and Kjos proposed the use of their equation for the determination of the initial and replacement media size Chat Online; Energy efficient cement ball mill fromconcrete wet ball mill frankston

Any of your enquiry will be highly appreciated.

Enquiry Now