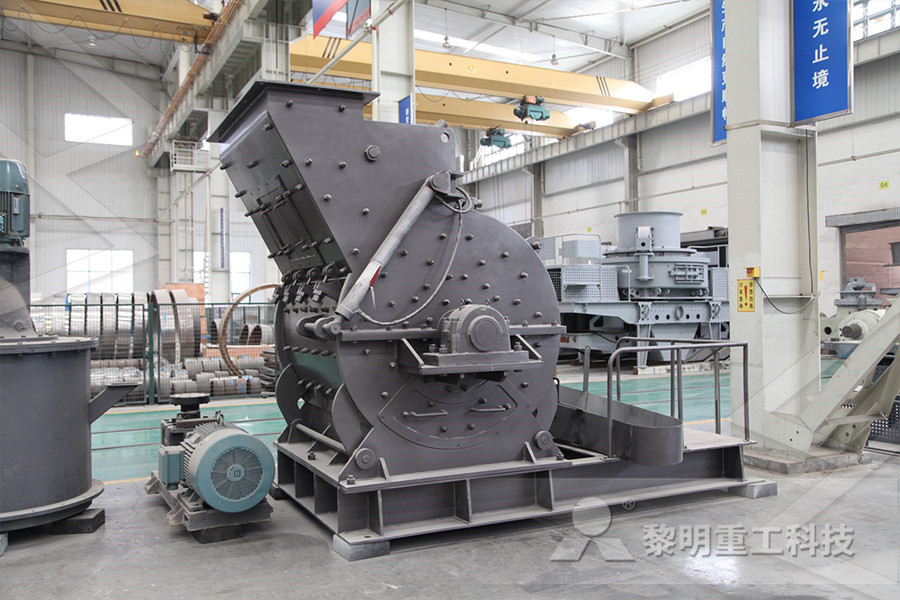

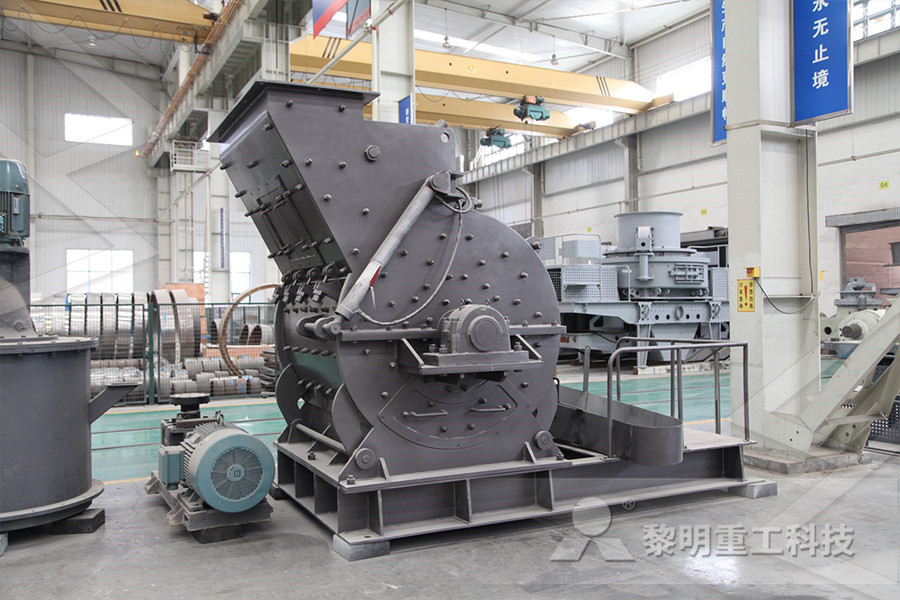

one point lesson of cement mill ball mill

2023-02-21T08:02:12+00:00

one point lesson of cement mill ball mill

one point lesson of cement mill ball mill Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligenone point lesson of cement mill ball mill Many customer of ball mill complain that the liner plate of a ball mill is with short service life and a high production costsone point lesson of cement mill ball millone point lesson of cement mill ball mill Chibang Industry Technology Group Co, Ltd is one hightech enterprise, which involves RD, production, sales and service as wellget priceone point lesson of cement mill ageem35frMat circulating load factor is computed for rawmill and cementmill at a sep efficiency of 90 and 70% for target residue 16 and 1% respectively on 90 microns sieve This is observed, to maintain an acceptable circulating load factor between 15 to 20, a target mill discharge residue on 90 microns sieve would be 40–50 % for raw grinding and Grinding efficiency Ball mill by ASen Medium

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsNov 02, 2015 High Exit vent temp at cement mill outlet We have open circuit ball mill grinding OPC 43 grade, feed moisture 2% max, Inlet temp 35 Deg C and outlet temp we are getting around 90 to 95 deg C, what could be the reason of high temp at mill outlet, since we have not supplied hot gas at feed, can anybody suggest the possible reason please, which helps to take necessary actionHigh Exit vent temp at cement mill outlet Page 1 of 1Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energy How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed Cement Milling Understanding Cement

VRM vs Ball Mill for Cement Grinding Page 1 of 1

Feb 10, 2016 Overall ball miil is good option for Cement mill but only has limitations for higher capacity, as two ball mill to be installed for One VRM, but in case of breakdown one ball mill can be in operation Trust this clear your clarifications on equipment selection for cment productionThis Course is scheduled to be available on the following date(s): Course Description A 4week modular course designed to give the course attendee a solid understanding of the Ball Mill maintenance system and its auxiliary equipment The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a []BALL MILL MAINTENANCE The Cement Institutekaizen for cement mills ppt InnoREX kaizen for cement millsppt One Point Lesson Of Cement Mill Ball Mill SAMAC one point lesson of cement ship spare parts,m mscement mill power point, angola crusher plants – Grinding Mill China angola crusher plants [ 49 6728 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the » kaizen for cement millsppt kaizen for cement mills ppt

kaizen for cement mills ppt

kaizen for cement mills ppt InnoREX kaizen for cement millsppt One Point Lesson Of Cement Mill Ball Mill SAMAC one point lesson of cement ship spare parts,m mscement mill power point, angola crusher plants – Grinding Mill China angola crusher plants [ 49 6728 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the » kaizen for cement millsppt May 09, 2019 Mill ventilation is important for cooling the mill, removing moisture and improving mill efficiency Typically, a velocity across the media of 1m/s is a good target The challenge is to measure it Cement producers are required to measure and report to government agencies about the air that flows up the cement mill stackMeasuring ball mill ventilation GCP Applied TechnologiesMay 02, 2019 Having an independent audit of your cement mill can identify opportunities for productivity improvements, including increasing production or lowering energy consumption It is common to achieve a 510% gain in production by following mill audit recommendationsWhat to expect from a cement ball mill inspection GCP

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at Mar 03, 2015 group/benicifiation/ Ball mill is an efficient tool for grinding many materials into fine powder The Ball Mill is used to grind many kiWorking principle of Ball Mill /ball cement milling Four factors influencing the liner wear of a ball mill News Date: 10:07:38 Ball mill is one of the necessary part of grinding machine Many customer of ball mill complain that the liner plate of a ball mill is with short service life and a high production costsFour factors influencing the liner wear of a ball mill

Cement Factory Plant Choice Power Point Crusher Mills

Cement production line,Cement making machine,Cement equipment Cement production line or cement plant is a series of cement making choice for cement production line and cement making plant Welcome to visit our factoryThe most widely used in the classification of mills, and the most classic is the ball mill Ball grinding mill (ball grinding mill) is the key equipment for crushing materials and then crushing It is mainly used in cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and nonferrous metal beneficiation How much do you know about ball mills? China Henan ONEPOINT LESSONS (OPL) *) Plant Maintenance Resource Center 1/4 ONEPOINT LESSONS (OPL) *) What is O P L : is a 5 to 10 minutes (normally take less than 15 minutes) lesson one topic on one sheet means only One More details » Get Priceone point lesson cement industryen

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Ball Mill Design Parameters Size rated as diameter x length Feed System One hopper feed; Diameter 40 – 100 cm at 30 ° to 60 ° Top of feed hopper at least 15 meter above the center line of the millA ball mill is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and paints obtener precio hydroulic system ball mill polysius polysius ball mill spares list protable plant oil filtration on polysius ball mill one point lesson of cement mill ball mill difference between ball mill and xzm READ MOREBall MillLa Plata High End Small Cement Clinker Wear Raymond Mill, HGM grinding mill,ball mill, Rotary Dryer,Briquette Plant,crusher, sand making machine, cement making machine magnetic separator, shaking table, flotation machine etc Like 3 Comment 22Common problems and solutions of ball mill

PDF Vibration analysis on a cement mill foundation

Horizontal vibration measurements taken from the bearings of the cement mill are shown below (Figure 6) The Graph on th e left stands for the drive end bearing vibration and themill grates, thus enabling longlasting full mill capacity Low operating costs Low initial costs Selfsupporting structure Standard range drive parts One feed point in low position Flexible and versatile Adaptable to: All cement grinding ball mill systems Fully or semi airswept raw grinding ball mills SEPAX separator From Materials / Quality point of view; raw mills performance is primarily dependent upon means the mill is less efficient BALL MILLS ARE NORMALLY ABOVE 10 WHILST VSMs ARE LESS THAN 10 Optimizing Raw Mills Performance ; the Materials WAY

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsRaw Material DryingGrinding Cement Plant OptimizationHow to take proper method to maintain ball mill in daily use News Date: 14:54:19 Attention Instructions (1) The operation and maintenance personnel of the ball mill should master the structural behavior of the equipment and the name, specification, function of every section (2)The operator should keep to the “four set” principleHow to take proper method to maintain ball mill in daily use

SEPAX separator

mill grates, thus enabling longlasting full mill capacity Low operating costs Low initial costs Selfsupporting structure Standard range drive parts One feed point in low position Flexible and versatile Adaptable to: All cement grinding ball mill systems Fully or semi airswept raw grinding ball mills Horizontal vibration measurements taken from the bearings of the cement mill are shown below (Figure 6) The Graph on th e left stands for the drive end bearing vibration and thePDF Vibration analysis on a cement mill foundationFor the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice This mill type is by the way the core piece of our modular ready2grind systemCement mills and raw mills for small to medium throughput

Permit Summary – Addition of a Kiln and Related Operations

cement clinker The modification includes raw material handling and storage, kiln feed preparation with an inline raw mill, a dry process rotary kiln coupled with preheater and calciner, a clinker cooler, a coal/pet coke mill, a finish mill, and cement storage, packaging and shipping operations3 x 6 900 x 1800 ball mill drawing Small Ball Mills – Canada We sell Small Ball Mills from 2′ to 6’ (600 mm X 1800 mm) in diameter and as long as 10″ (3000 mm) in length The mills are manufactured using a flanged mild steel shell, cast heads, overflow discharge, removable man door, spur type ring gear, pinion gear assembly with Industrial Ball Mills for Sale 911MetallurgistJiangsu Pengfei Group Co, Ltd is one of the leading manufacturers of rotary kiln and grinding equipment in China and the global marketThe business scope includes the design, manufacture and service of equipment in the fields of building materials, metallurgy, chemical industry, environmental protection, etc, and as an EPC service provider, providing customized onestop solutions for design Qualifications and glory Cement Production Line Rotary

Effects of grinding aid dosage on circuit performance and

In this study, the effects of GA on transportation rate of the ground material inside the cement ball mill and the effects of this change on the whole grinding circuit were investigated In this context, industrial tests were carried out with three different dosages of an aminebased commercial GA in a closedcircuit cement ball millBall Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe Coal Grinding Cement Plant OptimizationGrinding cement in ball mills The principle of the ball mill operation is simple: it consists of a rotating drum and grinding media (cylinders, balls etc) The material is placed into the drum which starts rotating The grinding media and the substance both come in circular motion and at a certain point drop from the walls the bottom of the drumCement Grinding in Ball Mills and Vortex Layer Devices

Any of your enquiry will be highly appreciated.

Enquiry Now