and operation and parts of gyratory crusher

2020-03-18T19:03:07+00:00

Gyratory Crusher an overview ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging openingThe Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil systemGyratory Crusher ComponentsSpare parts The primary crusher plays a crucial role in the size reduction process Even small improvements in uptime or throughput have a significant impact on the productivity of the entire operation Highquality primary gyratory crusher parts increase the crushing performance and reduce the unexpected downtimePrimary gyratory crusher parts

Gyratory Crushers

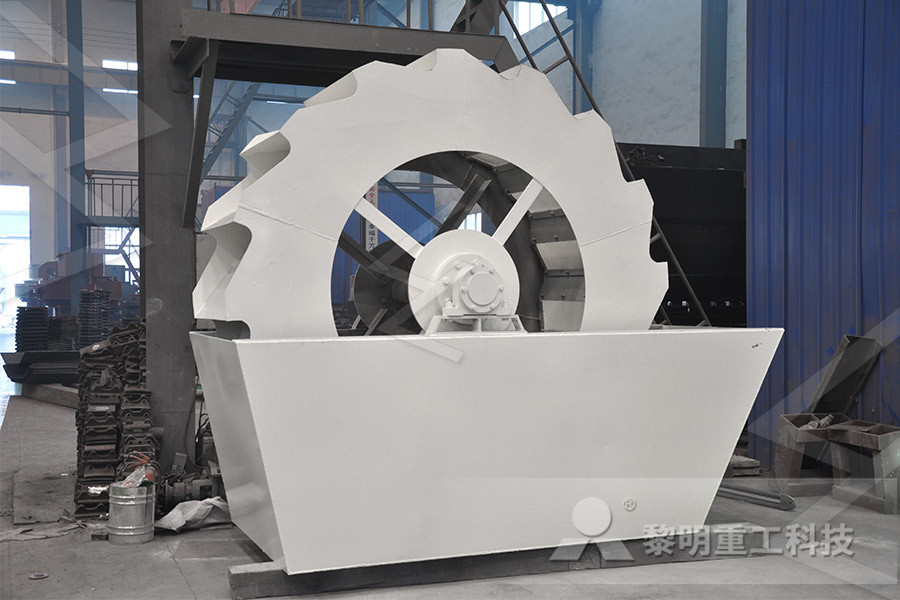

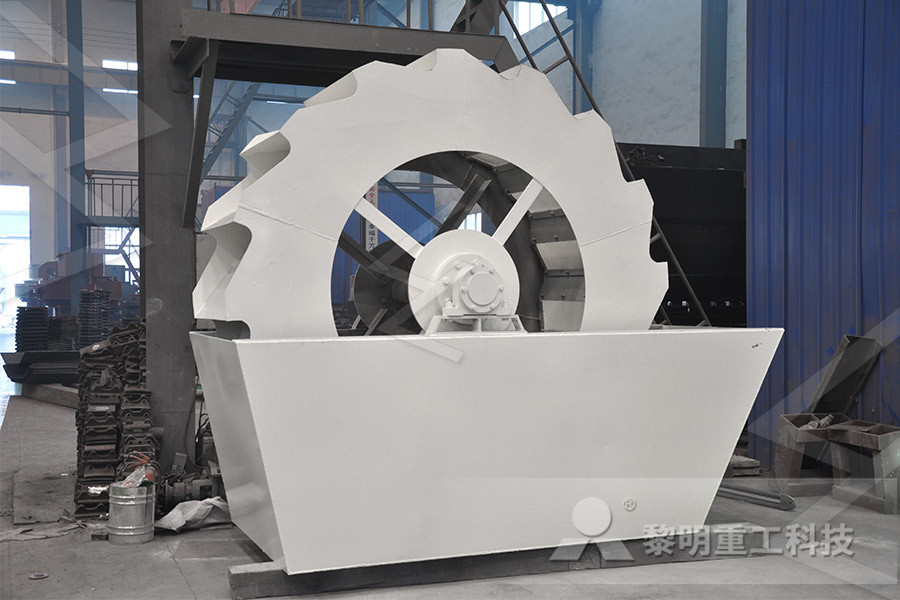

The below image shows a sectional view of a typical gyratory crusher This type of machine is, by virtue of chronological priority, known as the “standard” gyratory crusher Although it incorporates many refinements in design, it is fundamentally the same crusher that first bore the name of “gyratory”; its crushing chamber is very much the same shape; the motion is identically the same Lowest cost per tonne in operation and lowest total cost of ownership Through a combination of all these features, the TSUV Gyratory Crusher achieves the lowest cost per metric tonne in operation of any crusher on the market and gives you the lowest total cost of ownership This translates into a reduced environmental impactNew digitalenabled TSUV Gyratory Crusheroperation and parts of gyratory crusher crusher parts com 2020 6 2ensp0183enspprimary gyratory crusher parts the primary crusher plays a crucial role in the size reduction process even small improvements in uptime or throughput have a significant impact on the productivity of the entire operation high quality primary gyratoryOperation And Gyratory Crushing Equipment Parts

operation and gyratory crusher parts

operation and gyratory crusher parts 16239 yesweschoolit operation and parts of gyratory crusher operation and parts of gyratory crusher Crushing Equipments SAM stone crushing equipment is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone 01/01/2016 Gyratory crushers can accept 8–10% moisture in operation, but the fine content should be preferably less than 10% The crushing action in gyratory crushers is regarded as rings or ‘helics’ (spirals) of feed down through the crusher of which a single section may be regarded as similar to the jaw crusheroperation of a gyratory crusherCrusher wear studies for better productivity columbia steelCrusher wear studies by columbia steel take the guesswork out of cone liner jaw plate and gyratory wear part choices benefiting your operation with better production and less downtime crusher oems generally offer a limited choice of wear part designs and these are usually based on Gyratory Crusher Operation In Sri Lanka

Gyratory Crusher Components

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil systemDec 11, 2020 Tips for process layout of gyratory crusher December 11, 2020 mindmingles Tipes 0 With the development of sand and gravel aggregate production in the direction of green, intelligent and largescale, the gyratory crusherTips for process layout of gyratory crusher SifetBaboThe below image shows a sectional view of a typical gyratory crusher This type of machine is, by virtue of chronological priority, known as the “standard” gyratory crusher Although it incorporates many refinements in design, it is fundamentally the same crusher that first bore the name of “gyratoryGyratory Crushers

Parts Of A Gyratory Crusher And Its Principle Of Operations

Parts Of A Gyratory Crusher And Its Principle Of Operations Jan 01, 2016 Figure 51 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of Jan 23, 2014 Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime Gyratory crushers can SafeSet Application: Gyratory CrusherJan 01, 2016 54 Gyratory Crusher Operation Most crushing operations are performed under dry conditions Water is only used occasionally as a lubricant to wash or flush the fines and sticking material on crusher surfaces Gyratory crushers can accept 8–10% moisture in operationGyratory and Cone Crusher ScienceDirect

Primary Gyratory Crusher Operation

Process Operation Of Gyratory Crusher Process operation of gyratory crusherThe primary gyratory crusher offers high capacity thanks to Secondary breakers Pit amp Quarry Equipment Operations Sep 02 Most operations will use a gyratory jaw or impact crusher The basis weight of gyratory crusher machine is usually 23 times of the weight of the main part, and the basis weight of jaw crusher machine is 510 times the weight of the machine itself; 3 It can be packed to the mine, and large gyratory crusher The Advantages and Disadvantages of Gyratory Crusher operation and parts of gyratory crusher crusher parts com 2020 6 2ensp0183enspprimary gyratory crusher parts the primary crusher plays a crucial role in the size reduction process even small improvements in uptime or throughput have a significant impact on the productivity of the entire operation high quality primary gyratoryOperation And Gyratory Crushing Equipment Parts

operation and gyratory crusher parts

operation and gyratory crusher parts 16239 yesweschoolit operation and parts of gyratory crusher operation and parts of gyratory crusher Crushing Equipments SAM stone crushing equipment is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher Construction of Gyratory Crusher Simpler operation and maintenance Construction of gyratory crusher: HGT gyratory crusher is a very largescale equipment In the design, it pays special Construction of Gyratory CrusherThe Qiming Casting primary gyratory crusher wear parts have the most important role in rock size reduction in mine operations as the crushing process starts from a primary crusher The highest Gyratory Crusher Wear Parts Wear Parts For Industry

Crusher Wikipedia

A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones A cone crusher breaks rock by Process Operation Of Gyratory Crusher Process operation of gyratory crusherThe primary gyratory crusher offers high capacity thanks to Secondary breakers Pit amp Quarry Equipment Operations Sep 02 Most operations will use a gyratory jaw or impact crusher Primary Gyratory Crusher OperationPrimary Gyratory Crushers In Operation Primary crushing with gyratory crushers The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening which provides a much larger area than that of the jaw crusher and the continuous operation principle while the reciprocating motion of the jaw crusher Primary Gyratory Crushers In Operation

Top service TSUV Gyratory Crushers Safer, smarter and more

Unlike other gyratory crushers, which require workers to get in underneath the crusher to perform maintenance tasks – a highrisk operation – the TS range allows service and maintenance to be Dec 11, 2020 Tips for process layout of gyratory crusher December 11, 2020 mindmingles Tipes 0 With the development of sand and gravel aggregate production in the direction of green, intelligent and largescale, the gyratory crusherTips for process layout of gyratory crusher SifetBabooperation and parts of gyratory crusher 2019 9 2ensp0183enspgyratory crusher a gyratory crusher uses a mantle that gyrates or rotates within a concave bowl as the mantle makes contact with the bowl during gyration it creates compressive force which fractures the rock the gyratory crusher Operation And Parts Of Gyratory Crusher

Cone Crusher Working Principle Animation Engineering

Aug 15, 2012 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less operation and gyratory crusher parts 16239 yesweschoolit operation and parts of gyratory crusher operation and parts of gyratory crusher Crushing Equipments SAM stone crushing equipment is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher operation and gyratory crusher partsMay 13, 2019 Cone and gyratory crusher considerations Make sure the cone crusher does not get ring bounce or chatter Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber Low oil temperature should prevent operation of the unit High oil temperature should stop the crusher Tips to maximize crushing efficiency Pit Quarry : Pit

Parts Of A Gyratory Crusher And Its Principle Of Operations

Parts Of A Gyratory Crusher And Its Principle Of Operations Jan 01, 2016 Figure 51 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of Jan 23, 2014 Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime Gyratory crushers can SafeSet Application: Gyratory CrusherGyratory Crusher Wear Parts The primary gyratory crusher wear parts have the most important role in rock size reduction in mine operations as the crushing process starts from a primary crusher The Gyratory Crusher Parts For Popular Brands, Aftermarket

Any of your enquiry will be highly appreciated.

Enquiry Now