main faults of mobile jaw crusher in

2023-09-17T19:09:39+00:00

Main Faults of Mobile Jaw Crusher in Operation

Main common faults in the operation of mobile jaw crushers are summarized as follows: 1, product granularity becomes coarse This is the result of serious wear and tear in lower 4 Other common faults A Damaged feed hopper bolts Too much feed Solution: The feeding amount, feeding granularity and speed need to meet the requirements of the Common Fault Causes And Solutions of Jaw CrusherOpen sidebar changjiangsx; ; Repository main faults of mobile jaw crusher in operationmd

Main Faults Of Mobile Jaw Crusher In dermahausde

the crusher often vibrates main reason: 1) for spring cone breaking, when the spring tension of the crusher is not enough, the crusher will often vibrateElectric motor fault often Jaw Crusher Bearing Temperature Limit and Failure Solution Jaw crusher is the main ore or stone crushing plant in sand industry Thus fever problem is caused 3 moving jaw What Are Major Problems In Jaw Crusher? Crusher Mills, In order to balance the load, the energy of the idle stroke is accumulated when the moving jaw leaves the fixed jaw, so that the energy can be fully released during the working main faults of mobile jaw crusher in

main faults of mobile jaw crusher in operation

In the operation process of jaw crusher, there might be some commonly seen faults, which will cause various problems of jaw crusher Knowing how to solve these faults will Fault maintenance of jaw crusher 19 Shaking of Broken Toothed Plate Accompanied by Metal Impact Sound Reason: The broken toothed plate is loose, and the fixing bolt is loose or broken Solution: Repair the broken gear plate, tighten the fixing bolts or replace the damaged bolts 20 Impact Sound Generated by Connecting Rod Device23 Common Faults of Jaw Crusher with SolutionsThe jaw crusher is common faults in the work are as follows: 1 Failure phenomenon: crushing plate jitter, the sound is not normal Reasons: The lining loose Impact Crusher Fault Mobile Crusher Philippines Common Faults of Mobile Impact crusher First, Mobile Impact crusher vibration: 1 the material is too large Crusher Common Faults Crusher Mills, Cone Crusher, Jaw

main faults of mobile jaw crusher in operation

Jaw Crusher Faults borderlinegranadaes Jaw Crusher Faults Common jaw crusher mon jaw crusher faults ihse the jaw crusher is a single toggle jaw crusher, character the risk of failure on the main frame, as with a operation with common rock materials more details softstarter handbook abb abb will not take any responsibility for In Europe, owners who have operated both mobile and stationary crushers prefer the mobile units By eliminating the need for truck drivers, mobile crushers reduce mine manpower requirements and Mobile Crushers Mineral ProcessingFor example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm The main parts and main technical parameters of a jaw crusher are presented below 1 Feed Chute 2 Drive Flywheel 3 Vbelts 4 Electric motor 5 Motor Stand 6 Settings and Damping Group 7 Hydraulic Cylinder 8 Toggle Plate 9 Swing Jaw 10 What is a Jaw Crusher? – MEKA Crushing Equipment

Main Faults Of Mobile Jaw Crusher In dermahausde

Main Faults Of Mobile Jaw Crusher In impact crusher common faultsJaw crusher is the main ore or stone crushing plant in sand industry thus fever problem is caused 3 moving jaw bearing bore is machined with large errorsJul 15, 2020 phone: +0086371, In fact, the concept of mobile and semimobile crushing plants has arouse for a long time, but it has not been realized until recent years, mainly because most machines are very heavy, it is not easy to move them Mobile Crusher Eastman Rock Crusher Main Faults Of Mobile Jaw Crusher In Operation main faults of mobile jigs gold ore in operation Home> high energy saving brand mini ball mill>main faults of mobile jigs gold ore in operation is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation The Gold Stryker® GS7000LDuses a Main Faults Of Mobile Jaw Crusher In Operation Molino de

Crusher inspections Outotec

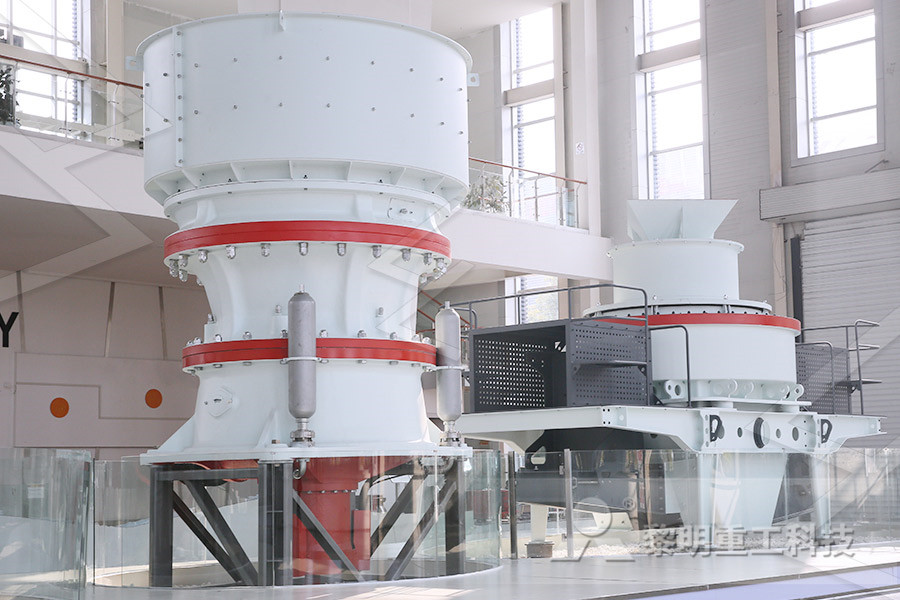

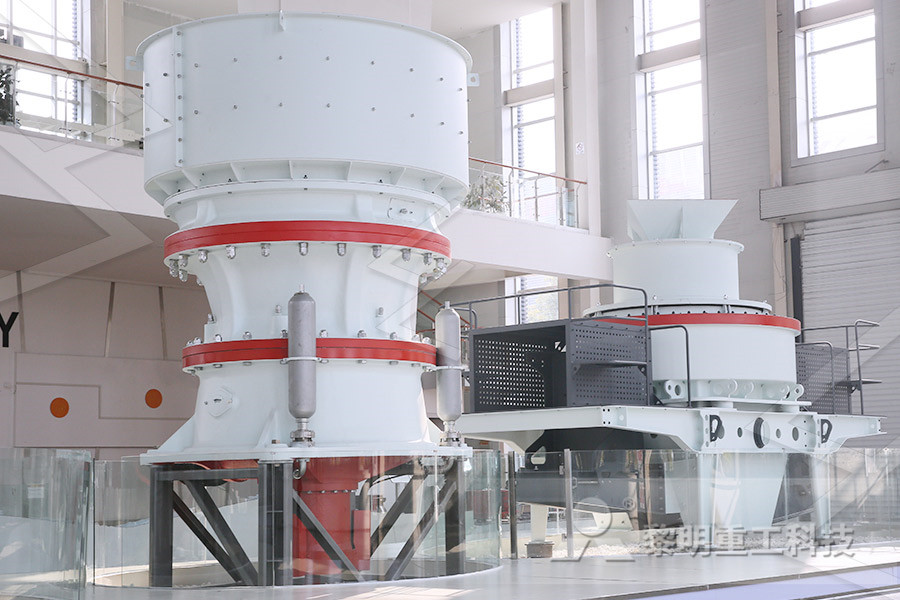

Crusher inspections Outotec Undetected issues can lead to poor crusher availability, increased repair costs, HSE problems, unplanned downtime and production losses at your production plant Rely on Outotec to keep your crushers running Avoid undetected crusher issues and consequently extend or maximize its performance Menu30 Aug 2012 The latest advancement within ® crushing and Initially launched in 2011 began implementing a wide ranging upgrade to its plant control system to coincide with the electronic engine information and fault code support while retaining houses the main operational software major faults on crusher plants biurobonusplWith the advancement of technology and the increase in customer demand, mobile jaw crushers are favored by more and more customers, especially in the sand making industry with strong material mobility Due to the large volume of the rock after mining, it is not ideal to use the secondary crushing machinery to crush it directlyMobile Jaw Crusher

What Are Major Problems In Jaw Crusher? Crusher Mills,

Jaw crusher is the main ore or stone crushing plant in sand industry Thus fever problem is caused 3 moving jaw bearing bore is machined with large errors what are the common problems associated with the jaw crusher In fact, the concept of mobile and semimobile crushing plants has arouse for a long time, but it has not been realized until recent years, mainly because most machines are very heavy, it is not easy to move them Therefore, most Mobile Crusher Eastman Rock Crusher Disadvantages of mobile (portable) stone crusher machines The equipment is complicated and expensive, and the onetime investment is too large, which is economically unbearable for some users; The equipment that can be carried is limited, and largescale open mining need more than one portable crushing station to meet the large capacityAdvantages and Disadvantages of 4 Types of Stone

USA1 Jaw Crusher Google Patents

Incorrect operation of the material crusher plant, in particular if a noncrushable element, eg a steel element, enters the crushing chamber, can result in an overload of the crusher ThisOur range of mobile jaw crushers is one of the most comprehensive on the market, led by the international bestselling Sandvik QJ341 mobile jaw crusher Our mobile cone crushers are designed to provide the ultimate in versatility; Mobile Crushers, Mobile Jaw Crushers Mobile 2 Crusher Bearings: Knowing the Basics Leads to Better Care Compression Crushers In compression crushers, high startup torque, shock loads and vibration demand highperforming antifriction bearings that can operate reliably with minimal heat generation Jaw Crushers Most operations prefer jaw crushers for primary crushing A large feedKnowing the Basics Leads to Better Care Timken

Lokotrack Series Mobile Crushing Plants for Contractors

In cases where noncrushable material like a piece of iron enters the crusher cavity and generates a high pressure, the relief valve is opened and releases the hydraulic oil from the cylinders As a result, the crusher cavity opens and the non Poor material finishes could be due to either bluntness in the tool used, or improper feed speed ratio It may also be caused by the wrong dimensions of the tool for the job at hand in terms of the sizes, quality or match with the material To resolve this, it is important to choose the right tool and setting for the job and material[Checklist] 10 Common Problems with Machine Tools Our design engineers are never done researching and testing tooling upgrades that improve the safety and maintenance of your crusher As part of our improvement efforts, we work with our customers to develop and supply the tooling options that they request The result is a growing array of gyratory and cone crusher tooling upgradesImprove safety and maintenance with our gyratory tooling

Any of your enquiry will be highly appreciated.

Enquiry Now