ball mill grinding liner kenya

2022-07-04T08:07:31+00:00

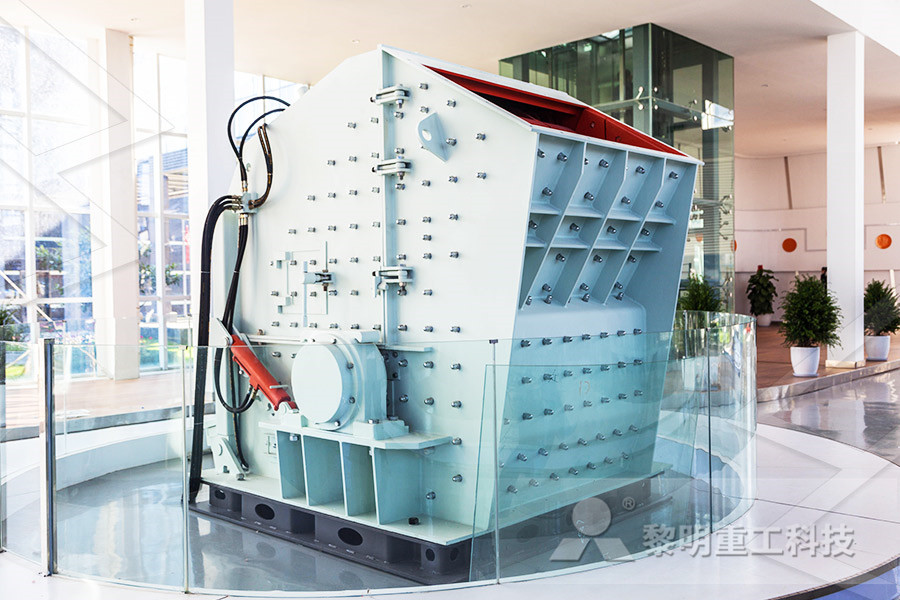

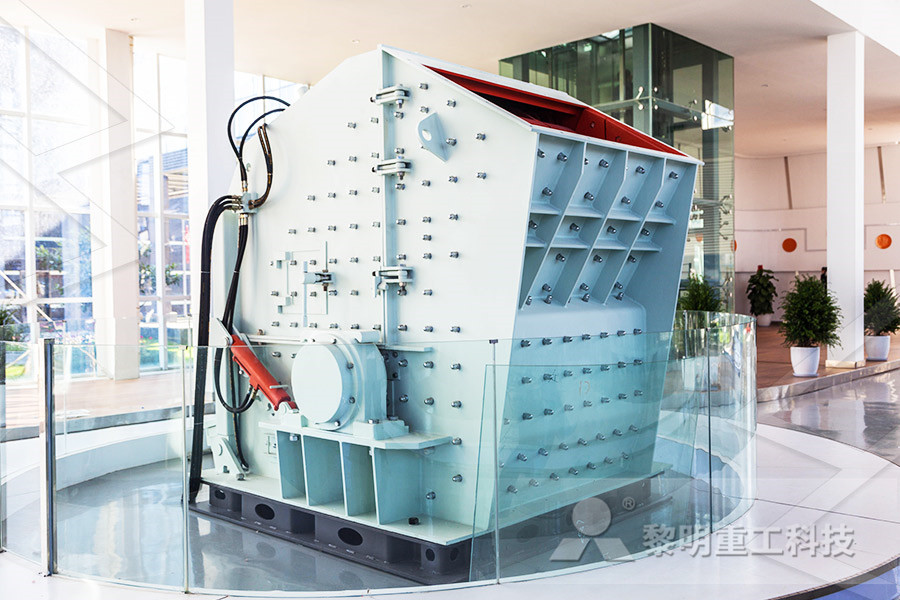

Ball mill liner Wear Parts For Industry Qiming Casting

Ball mill liners are the main replacement wear parts for ball mills These liners are manufactured by wearresistant material and rubble As a wearresistant foundry, Qiming Casting Uses of a Ball Mill Liner The role of a ball mill liner is to give the mill heads protection against wear and tear thus increasing their lifetime and creating optimal grinding efficiency The design of a ball mill liner depends on the drilling Ball mill liner Magotteaux There are three ways for grinding media to pulverize materials: 1 Rolling: the grinding media rolls in the grinding chamber and pulverizes the material by selfweight 2 Ball Mill Grinding Media – Grinding Media Balls Cylpebs

Ball Mill Liners Selection and Design Ball Mill

The grinding mill liners are the main wearing part of the ball mill equipment The ball mill liner replacement should in time when the lining plate The manganese content of the ball mill liner is generally 1114%, and the carbon content is generally 090150%, most of which are above 10% At low impact loads, the Grinding Mill Liners AGICO CEMENTThe type of ball mill liner known as a shell liner, or The MVLTM, Magotteaux Variable Lift, covers a range of shell liners for everything from fine to coarse grinding These liners are efficient ball mill liner Magotteaux

ball mill liner Magotteaux

The type of ball mill liner known as a grate liner is designed for discharge efficiency It allows the discharge of ground materials via slots With the Magotteaux range of alloys and their Ball mills are the classic grinding plants: Around the world they are the most common installations Ball mills convince thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable Ball Mills Achelis Kenya 500 kgs per hour ball mill inside has liners can use over a lifetime good quality 55kw 11kw motor Ceramic Grinding Quartz Ball Mill In Kenya KSh 1 800 000 Energy saving ball mill Ball Mill Grinding Liner Kenya cafebliss

Grinding Mill Liners Mineral Processing

The high profile liner is designed to give the media the higher lift This type will be used in mills that are designed for primary grinding and as a result require the impact of the higher cascade Ball mills working as the secondary Qiming Machinery is one of the largest ball mill liner manufacturers in China Qiming Machinery’s ball mill liners are tailormade and developed in close collaboration with our customers Being the pioneer, Qiming Machinery ball mill liners are designed and produced based on the world’s largest bank of knowhow and experienceBall Mill Liner Qiming MachineryThe type of ball mill liner known as a shell liner, or The MVLTM, Magotteaux Variable Lift, covers a range of shell liners for everything from fine to coarse grinding These liners are efficient energy wise and make for low grinding media consumptionball mill liner Magotteaux

Ball mill liner Zimaksan Co

Ball mill liner One of the most common types of grinding machines used today in many industries is a ball mill This device works by using mass media balls made of solid materials, embedded in a compartment or container, in such a way that the material is crushed and powdered at the time of the cavity of the compartment on the material For ball mill work ribs are cast with the feed head liners to deflect the ball mass and minimize wear on the headliner itself In grate ball mill work there are no discharge head liners The discharge grates and grate assembly Ball Mill Liner Design Mineral Processing2 天前 In Recent Years, The Size Of The Lining Plate Of The Ball Mill Has Been Unified, The Width Is 314mm, The Length Of The Whole Lining Plate Is 500mm, The Half Lining Plate Is 250mm, The Thickness Is 4050mm, And The Mass Is About 4555kg Correlation ComparisonBall Mill Liner ( Rubber , Polyurethane ) Mill Rubber

Quality Grinding Media supplier Ball Mill Liners

HRC53 Ball Mill Liners For High Abrasion , 26m Grinding Media Balls Quick Details Nihard Discharge End Liners for Φ26m Rod Mill 1 Hardness: More than HRC53 2 International Standard: AS 20272002/Ni hard 1 Read More 09:20:31 Dia60mm High Cr Cast Balls Grinding Media for Minging Industry Contact Now 【 Grinding Media Ball 】 Steel ball, manganese, chrome, ceramic ball, etc 【 Common Steel Ball Sizes 】 40mm, 60mm, 80mm, 100mm, 120mm 【 Ball Mill Liner 】 Natural rubber plate, manganese steel plate, 50130mm custom thickness 【 Features 】 1 Effective grinding technology for diverse applications 2 Long life and minimum maintenance 3Ball Mills Industry Grinder for Mineral Processing JXSC Our ball mills for cement grinding deliver high grinding efficiency with reduced energy consumption and low maintenance 4000+ references worldwide Investors Ball Mill Liners brochure English PDF (3106KB) Download Energy efficient cement ball mill from

Ball Mills MechProTech

UP to 80% Critical speed and 40% Ball charge at maximum grinding power for shell BiDirectional Prolongs liner life by up to 70% without losing performance All cost effective and commercially available equipment, specialized and readily available Up to 13 MW on a single modular skid base FULLY MODULAR – PLUG PLAYBall Mill Working Principle And Main Parts Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder ball mill grinding liner kenya restaurantlespinsfr Ball mill liner is to protect the cylinder shell from the direct impact and friction of the grinding media and material Order Online Chat Now Download Brochure Share Get solution and support: I am interested in , raw material is , the production capacity is t/h, send to (*) Name: (*) Phone: Country: ProcessTechnology AdvantagesBall mill liner for ball mill ,Ball mill liner ,Ball mill steel liner

Ball Mills Industry Grinder for Mineral Processing JXSC

【 Grinding Media Ball 】 Steel ball, manganese, chrome, ceramic ball, etc 【 Common Steel Ball Sizes 】 40mm, 60mm, 80mm, 100mm, 120mm 【 Ball Mill Liner 】 Natural rubber plate, manganese steel plate, 50130mm custom thickness 【 Features 】 1 Effective grinding technology for diverse applications 2 Long life and minimum We have advance production facility and unique technology that creates efficient mill liner products and services Our mill liner has unit weight of 10 – 1200kg/ piece, with ApproRa50 surface finish and has longer liner wear life that is capable in increasing the mill’s volumetric capacityResminer Ball Mill Liner Supplier in China Ware Resistance Ball mill is a key equipment for grinding materials thus grinding ball mills are widely used in the mining beneficiation process, and it has a wide range of suitable grinding mineral and can works on wet and dry grinding processing our JXSC's ball mills are perfectly used for ores such as gold, iron, zinc ore, copper, etcBall Mill for Sale Grinding Machine JXSC Mining

SAG and Ball Mill Liner EB Castworld

Ball mills are smaller in diameter than length and can be used in either primary, secondary or tertiary grinding applications to reduce material from ~20mm to very fine product sizes measured in microns or mesh SAG and Ball Mill Liner system serves two purposes:UP to 80% Critical speed and 40% Ball charge at maximum grinding power for shell BiDirectional Prolongs liner life by up to 70% without losing performance All cost effective and commercially available equipment, specialized and readily available Up to 13 MW on a single modular skid base FULLY MODULAR – PLUG PLAYBall Mills MechProTechLiners optimized for your specific mill Features Fast reline as a liner covers up to 8 m² A Megaliner™ element integrates multiple lifter and plate rows and has a minimum number of attachment points In some cases, the lining consists of up to 80% fewer parts It covers a large area of up to 8 m² and is lightweight in relation to sizeMegaliner™ mill liners Outotec

Ball Mill Grinding Liner Kenya jawatourspl

Ball Mill Grinding Liner Kenya Grinding mill liners huaminsh (2)Light weight, thin thickness, energy saving and electricity saving The thickness of magnetic liner is very thin It is about 4050% of high manganese steel liner It can effectively reduce the load of ball mill, reduce the consumption of ball mill and increase The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 Lcapacity grinding chamber made of an abrasionresistant elastomer, put in vibrating motion by hightensile steel springs [28] (PDF) Grinding in Ball Mills: Modeling and Ball mill is one of the most commonly used mills for the crushing and grinding of mineral ore It is generally used to grind material down to the particle size of 20 to 75 μm and can vary in size from a small batch mill up to a mill with outputs of hundreds of tonnes per hourImpact energy of particles in ball mills based on DEM

Any of your enquiry will be highly appreciated.

Enquiry Now